Rubber for non-stub-bar mandril rubber hoop and preparation method of rubber hoop

A technology without material head and rubber, applied in the field of rubber products, can solve the problems of difficult disassembly and installation, fast thermal conductivity of iron hoops, heavy iron hoops, etc., and achieves the effect of convenient disassembly and installation, flat end and accurate size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

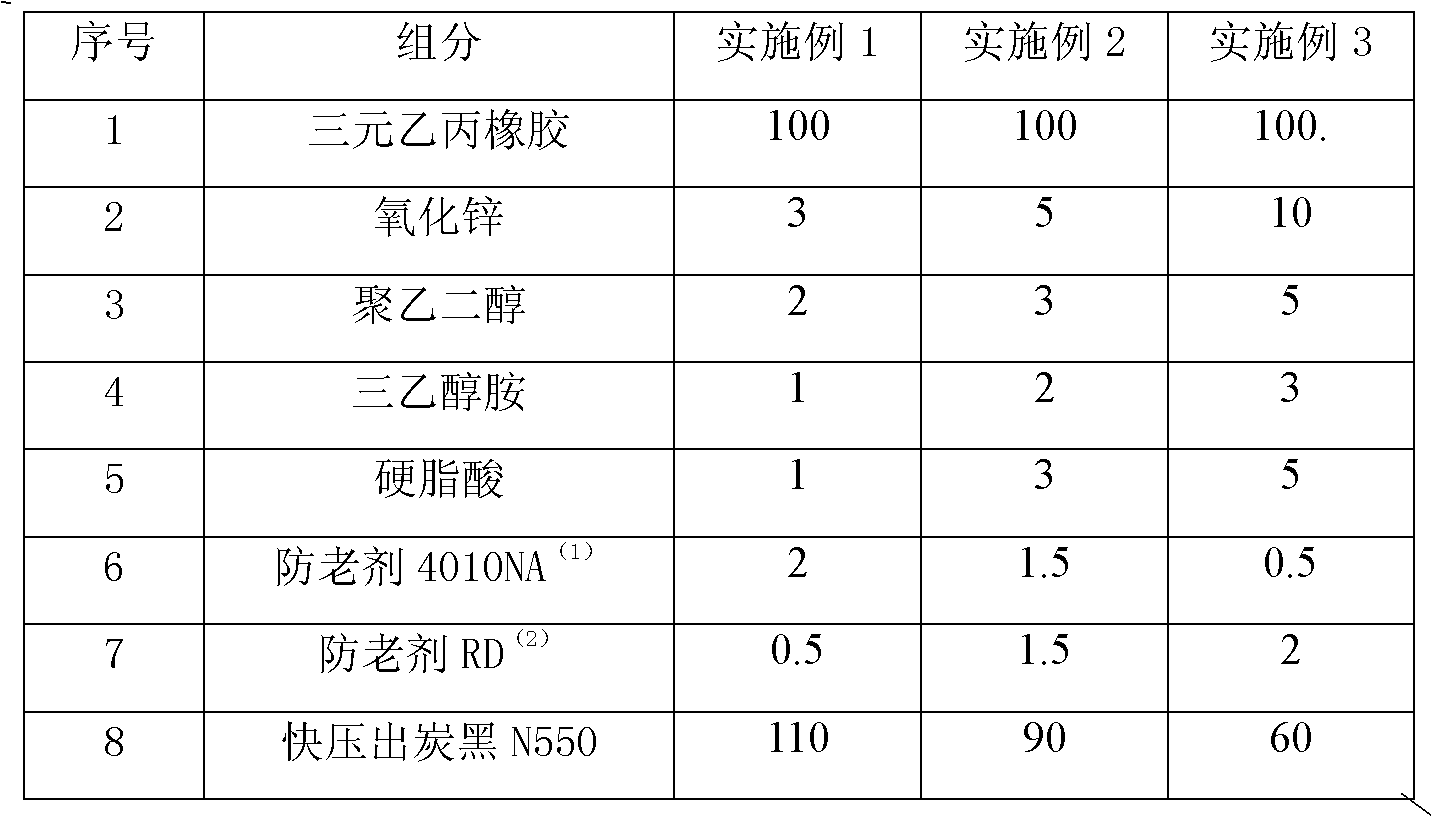

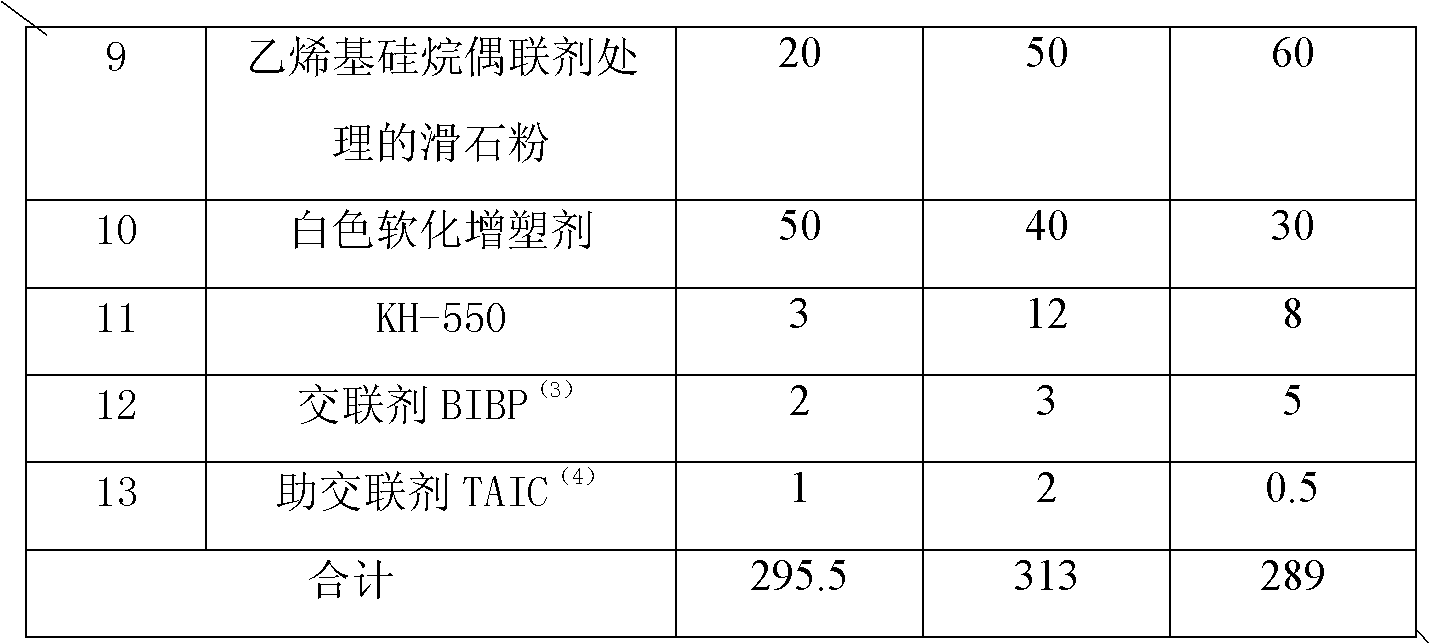

[0025] Based on the mass parts of each component

[0026]

[0027]

[0028] Manufacturing method of rubber band:

[0029] 1. Mixing: According to the formula of Examples 1, 2 and 3, put the raw rubber and large and small auxiliary materials into the internal mixer to fully mix. The process step is to add raw rubber and a small auxiliary material (including plasticizer, anti-aging Agents, coupling agents and neutralizers, etc.), adding carbon black, oiling, lifting the suppository high, and degumming. When the temperature reaches 120~123℃, the high position of the lift bolt (the high position of the lift bolt refers to the lifting of the top bolt in the internal mixer to a high position, and there is sufficient space for the rubber in the mixing chamber to act on the rotor of the mixer Turn down to make the rubber compound and auxiliary materials fully mixed). When the temperature reaches 180~185℃, the rubber will be discharged. The rotor speed of the internal mixer is 30-40r / min t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com