High-cold-resistant synthetic leather and preparation method of the high-cold-resistant synthetic leather

A synthetic leather and cold-resistant technology, which is applied in the preparation of high cold-resistant synthetic leather and the field of high cold-resistant synthetic leather, can solve the problems of brittleness, hardening and breaking of synthetic leather

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

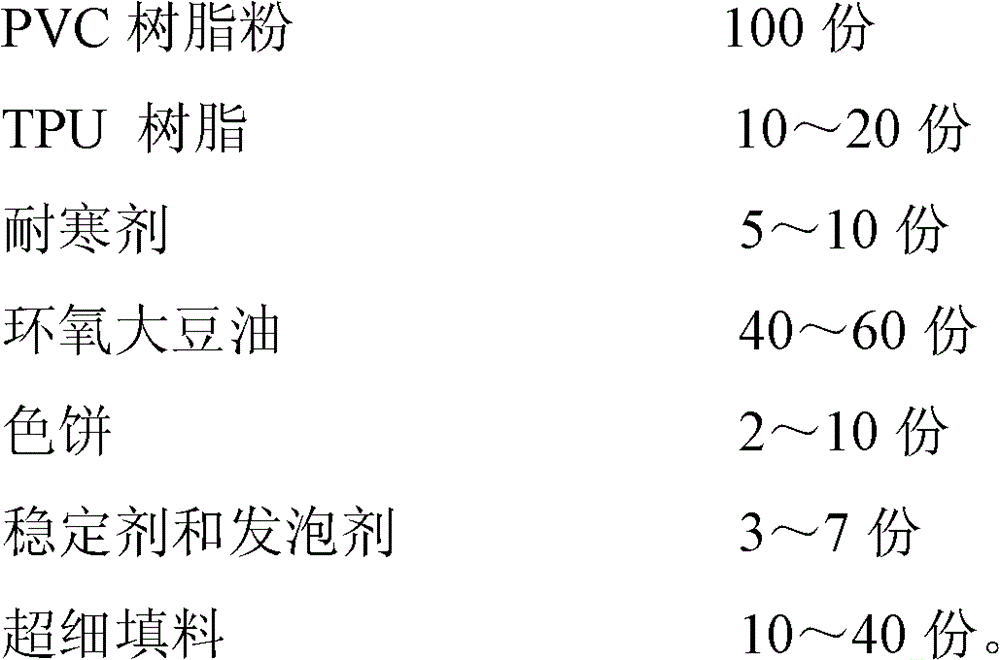

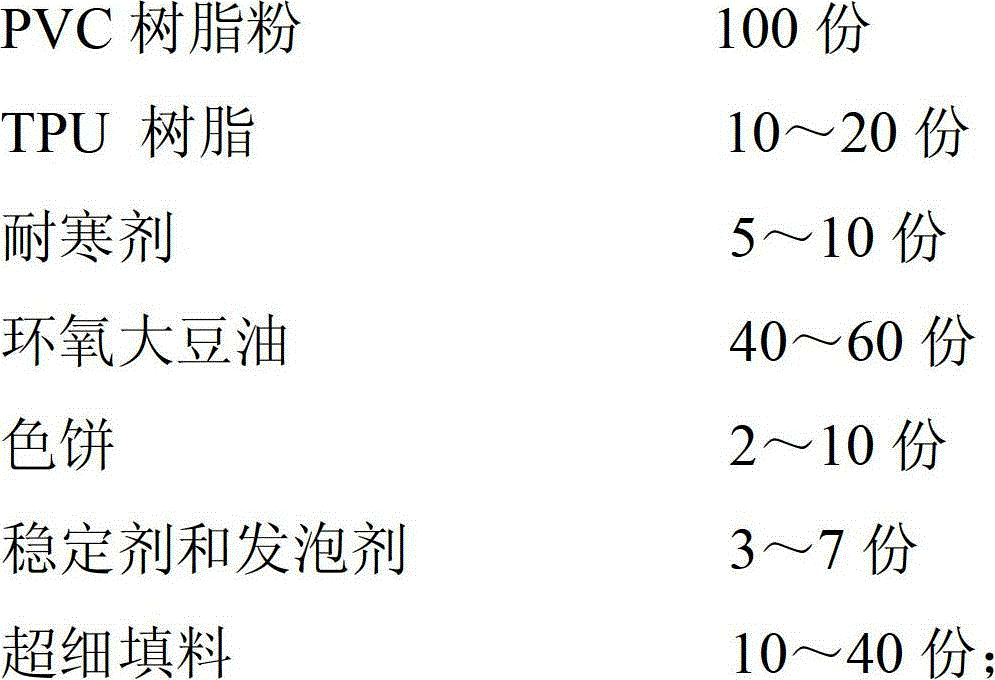

[0020] The raw materials of the high cold-resistant slurry and their proportions by weight are: 100 parts of PVC resin powder, 15 parts of TPU resin, 8 parts of cold-resistant agent DOA, 50 parts of epoxy soybean oil, 5 parts of color cake, 2 parts of potassium zinc stabilizer, 2 parts of azodicarbonamide, 30 parts of 2000 mesh superfine calcium carbonate.

[0021] According to the ingredients, the above-mentioned materials measured are input into the high-speed mixer through the pulse feeder, and the temperature is controlled at 100-150 ° C. After fully stirring, they enter the internal mixer, and the temperature is controlled at (150 ° C) for several minutes; After the base material (various fabrics) is opened, apply PU slurry (150°C), combine the fully mixed material with the base material with PU slurry, enter the second rolling mill (160°C) for kneading, and then After entering the four-roll calender (temperature 160-190°C) and calendering, it is cooled to room temperatur...

Embodiment 2

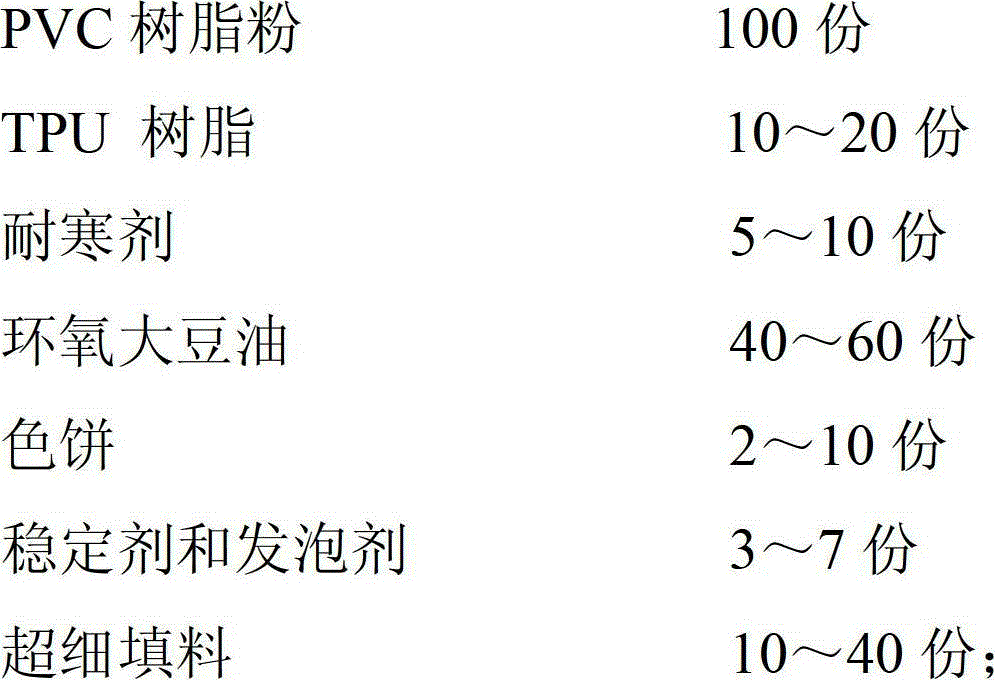

[0025] The raw materials of the high cold-resistant slurry and their weight ratios are as follows: 100 parts of PVC resin powder, 18 parts of TPU resin, 6 parts of DOZ cold-resistant agent, 25 parts of epoxy soybean oil, 8 parts of color cake, and 3 parts of barium-zinc stabilizer , 2 parts of azodicarbonamide, 20 parts of 2000 mesh superfine calcium carbonate.

[0026] According to the ingredients, the above-mentioned materials measured are input into the high-speed mixer through the pulse feeder, and the temperature is controlled at 100-150 ° C. After fully stirring, they enter the internal mixer, and the temperature is controlled at (160 ° C) for several minutes; After the base material (various fabrics) is opened, apply PU slurry (150°C), combine the fully mixed material with the base material with PU slurry, enter the second rolling mill (160°C) for kneading, and then After entering the four-roll calender (temperature 160-190°C) and calendering, it is cooled to room tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com