Water-based high-temperature-resistant oxidation-resistant inorganic paint and preparation method thereof

An inorganic coating and high-temperature-resistant technology, which is applied in the field of water-based high-temperature-resistant and anti-oxidation inorganic coatings and its preparation, can solve the problems of low anti-oxidation temperature, lack of universal applicability, and high cost of coatings, and achieve no pollution to the environment, preparation and coating process Simple and convenient, the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

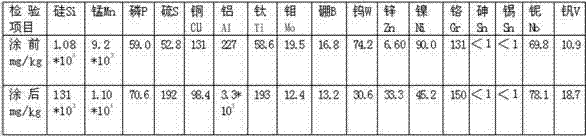

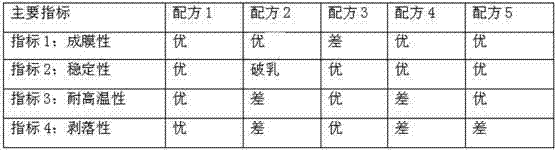

Image

Examples

Embodiment 1

[0033] Embodiment 1: The coating of the present invention is composed of the following components by weight ratio: 15 parts of water-based inorganic aluminum sol resin, 10 parts of alumina, 25 parts of bauxite, 15 parts of kaolin, 2 parts of silicon-acrylic emulsion, 32 parts of deionized water , 1 part of inorganic bentonite.

[0034] The preparation method is as follows: add 32 parts of deionized water, 15 parts of water-based inorganic aluminum sol resin, 10 parts of alumina, 25 parts of bauxite, and 15 parts of kaolin into a mixing pot in sequence, and stir at high speed for 30 minutes to obtain a mixture; Put the good mixture into a grinder for grinding. The fineness of the ground mixture is less than 50 microns, and then put it into the reaction kettle, slowly add 2 parts of silicon acrylic emulsion dropwise under low-speed dispersion, and control the temperature at 75°C. Keep warm for 2.5 hours, lower the temperature, add 1 part of inorganic bentonite at a low speed and...

Embodiment 2

[0036] Embodiment 2: The coating of the present invention is composed of the following components by weight ratio: 20 parts of water-based inorganic aluminum sol resin, 10 parts of alumina, 23 parts of bauxite, 8 parts of kaolin, 2 parts of styrene-acrylic emulsion, 35 parts of deionized water , 2 parts of hydroxypropyl methylcellulose.

[0037] The preparation method is as follows: add 35 parts of deionized water, 20 parts of water-based inorganic aluminum sol resin, 10 parts of alumina, 23 parts of bauxite, and 8 parts of kaolin into a mixing pot in sequence, and stir at high speed for 45 minutes to obtain a mixture; Put the good mixture into the grinder for grinding, the fineness of the ground mixture is less than 50 microns, then put it into the reaction kettle, slowly add 2 parts of styrene-acrylic emulsion dropwise under low-speed dispersion, the temperature is controlled at 60°C, after the dropwise addition is completed Keep warm for 3 hours, lower the temperature, add ...

Embodiment 3

[0039] Embodiment three: the coating of the present invention is made up of the following components by weight ratio: 30 parts of water-based inorganic aluminum sol resins, 15 parts of alumina, 15 parts of bauxite, 12 parts of kaolin, 10 parts of acetic acid tertiary carbonate emulsion, deionized water 15 parts, 3 parts sodium alginate.

[0040] The preparation method is as follows: add 15 parts of deionized water, 30 parts of water-based inorganic aluminum sol resin, 15 parts of alumina, 15 parts of bauxite, and 12 parts of kaolin into a mixing pot in sequence, and stir at high speed for 50 minutes to obtain a mixture; Put the good mixture into the grinder for grinding, the fineness of the ground mixture is less than 50 microns, then put it into the reaction kettle, slowly add 10 parts of acetic acid tertiary carbonate emulsion dropwise under low speed dispersion, control the temperature at 80°C, add dropwise After completion, keep warm for 2.75 hours, lower the temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com