Rubber with fluorescence response to pH value and preparation method thereof

A fluorescent response and rubber technology, applied in the direction of fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of physical, chemical and mechanical performance limitations, and achieve the effect of wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

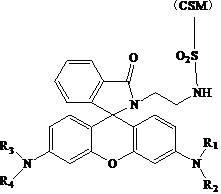

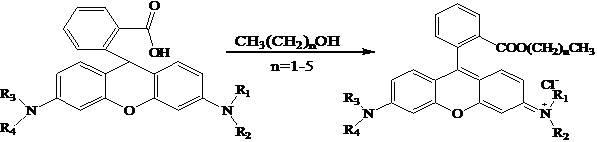

[0032] 1. Preparation of Rhodamine Ester

[0033] Measure 125mL of acetyl chloride and slowly add it dropwise to 500mL of absolute ethanol solvent containing 10g of rhodamine B. 2 Under protection, the reaction was incubated at 50° C. for 2 hours. Ethanol was distilled off under reduced pressure to obtain a crude product. The crude product was dissolved in 1000 mL of water, washed with ethyl acetate (3×500 mL), and the water was evaporated under reduced pressure to obtain 10.6 g of rhodamine B ethyl ester with a yield of 90%.

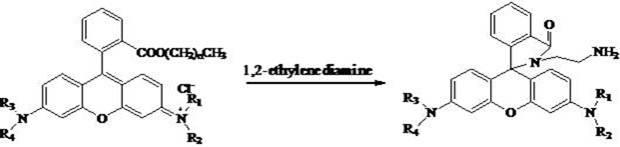

[0034] 2. Preparation of ethylenediamine substituted rhodamine

[0035] Dissolve 10 g of rhodamine B ethyl ester in 200 mL of 30°C methanol, and add 30 mL of ethylenediamine. The reaction mixture was heated to reflux for 1 hour, cooled to room temperature, and the methanol solvent was removed under reduced pressure. Add 1000mLCCl 4 , 2000mL of water, collected the organic layer, washed with water twice. The organic phase was dried with anhydrous s...

Embodiment 2

[0039] 1. Preparation of Rhodamine Ester

[0040] Measure 145mL of acetyl chloride and slowly add it dropwise to 500mL of anhydrous butanol solvent containing 13g of rhodamine B. 2 Under protection, the reaction was incubated at 35° C. for 3 hours. Butanol was distilled off under reduced pressure to obtain the crude product. The crude product was dissolved in 1000 mL of water, washed with ethyl acetate (3×500 mL), and the water was evaporated under reduced pressure to obtain 12.6 g of rhodamine B butyl ester with a yield of 86.3%.

[0041] 2. Preparation of ethylenediamine substituted rhodamine

[0042]Dissolve 12g of rhodamine B butyl ester in 230mL of 45°C methanol, and add 35mL of ethylenediamine. The reaction mixture was heated to reflux for 2 hours, cooled to room temperature, and the methanol solvent was removed under reduced pressure. Add 1000 mL of ethyl acetate and 2000 mL of water, collect the organic layer and wash with water twice. The organic phase was dried ...

Embodiment 3

[0046] 1. Preparation of Rhodamine Ester

[0047] Measure 140mL of acetyl chloride and slowly add it dropwise to 500mL of anhydrous pentanol solvent containing 12g of Rhodamine B, 2 Under protection, the reaction was incubated at 45° C. for 2.5 hours. The amyl alcohol was distilled off under reduced pressure to obtain a crude product. The crude product was dissolved in 1000 mL of water, washed with ethyl acetate (3×500 mL), and the water was distilled off under reduced pressure to obtain 12.6 g of rhodamine B amyl ester with a yield of 91.3%.

[0048] 2. Preparation of ethylenediamine substituted rhodamine

[0049] Dissolve 11 g of rhodamine B amyl ester in 200 mL of methanol at 45° C., and add 33 mL of ethylenediamine. The reaction mixture was heated to reflux for 1.5 hours, cooled to room temperature, and the methanol solvent was removed under reduced pressure. Add 1000mL cyclohexanone and 2000mL water, collect the organic layer and wash with water twice. The organic ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com