Catalyst for preparing polyalkyl glycol allyl amyl ether and preparation method thereof

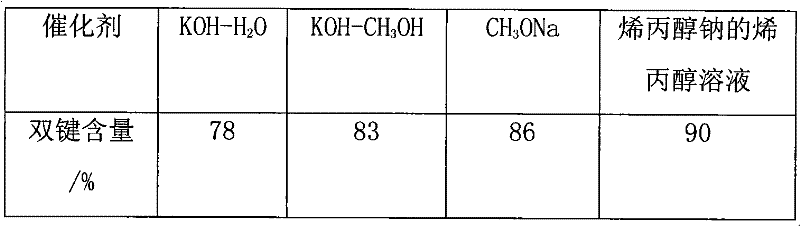

A technology of allyl polyoxyalkylene alkenyl ether and catalyst, applied in the field of catalysts, can solve the problems of reducing the purity of allyl polyoxyalkylene alkenyl ether and cannot be completely removed, and achieves the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

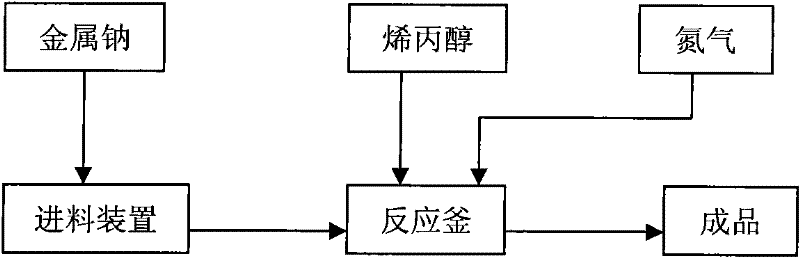

Method used

Image

Examples

Embodiment 1

[0027] Put 40Kg of allyl alcohol into a 100L reactor, cut 0.8Kg of sodium metal into small pieces and put it into the feeding device, feed nitrogen to replace the air in the reactor, keep the vent valve open and feed nitrogen, and feed the condenser Cool the water, open the feeding device, feed once every 10 minutes, 0.16Kg once, close the feed valve after adding the metal sodium, and continue the reaction until the reaction solution has no bubbles. The mass percent concentration of sodium allylate in the obtained allyl alcohol solution of sodium allylate is 7%.

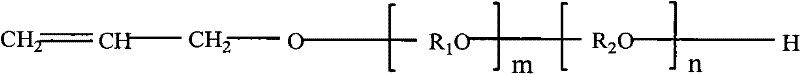

[0028] Add 348g of the above-mentioned catalyst into 2.0Kg allyl alcohol, drop into a 50L autoclave while stirring, and feed N 2 Substitute three times, raise the temperature to 100°C, introduce 1.5Kg of ethylene oxide, raise the temperature to 160°C, react for about 30 minutes, continue to add 16.7Kg of ethylene oxide, keep the reaction temperature at 160°C, and carry out polymerization under the pressure of 0.3Mpa....

Embodiment 2

[0032] Put 40Kg of allyl alcohol into a 100L reactor, cut 1.6Kg of sodium metal into small pieces and put it into the feeding device, feed nitrogen to replace the air in the reactor, keep the vent valve open and feed nitrogen, and feed the condenser Cool the water, open the feeding device, feed once every 10 minutes, 0.16Kg once, close the feed valve after adding the metal sodium, and continue the reaction until the reaction solution has no bubbles. The mass percent concentration of sodium allylate in the obtained allyl alcohol solution of sodium allylate was 13%.

[0033] Add 174g of the above catalyst into 2.0Kg allyl alcohol, drop into a 50L autoclave while stirring, feed N 2 Replace three times, raise the temperature to 100°C, introduce 2.0Kg of ethylene oxide, raise the temperature to 160°C, react for about 30 minutes, continue to add 28.4Kg of ethylene oxide, keep the reaction temperature at 160°C, and carry out polymerization under the pressure of 0.3Mpa. After 2 hours ...

Embodiment 3

[0037] Put 40Kg of allyl alcohol into a 100L reactor, cut 2.4Kg of sodium metal into small pieces and put it into the feeding device, feed nitrogen to replace the air in the reactor, keep the vent valve open and feed nitrogen, and feed the condenser Cool the water, open the feeding device, feed once every 10 minutes, 0.16Kg once, close the feed valve after adding the metal sodium, and continue the reaction until the reaction solution has no bubbles. The mass percent concentration of sodium allylate in the obtained allyl alcohol solution of sodium allylate was 19%.

[0038] Add 174g of the above-mentioned catalyst into 2.0Kg allyl alcohol, drop into a 100L autoclave while stirring, and feed N 2 Replace three times, raise the temperature to 100°C, introduce 5Kg of ethylene oxide, raise the temperature to 160°C, react for about 30 minutes, continue to add 71Kg of ethylene oxide, keep the reaction temperature at 160°C, and carry out polymerization under the pressure of 0.25Mpa, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com