Method for preparing billet yarns into color yarns

A grey yarn and colored technology is applied in the field of yarn manufacturing to achieve the effects of reducing production costs, saving water and saving heat energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Embodiment: 32S / 2 cotton yarn dyeing

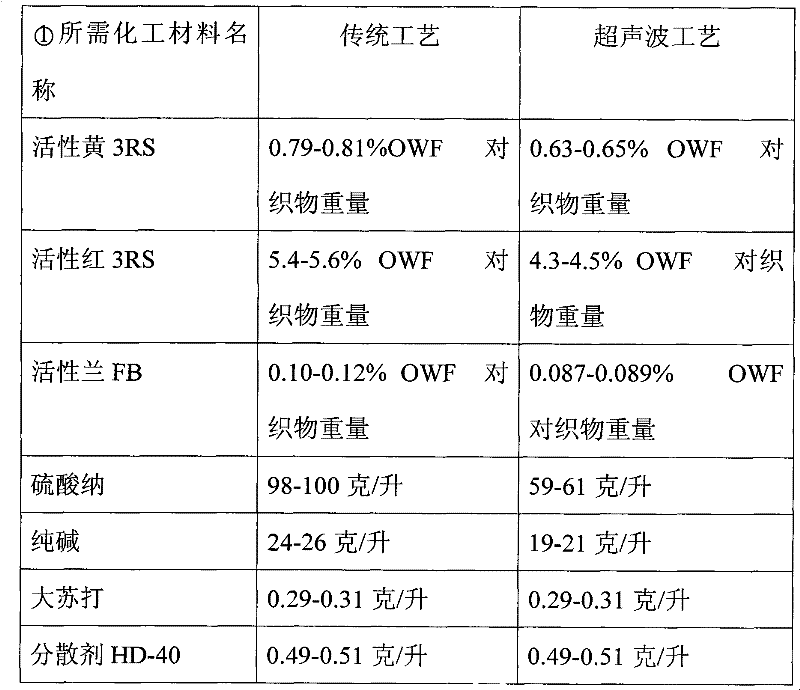

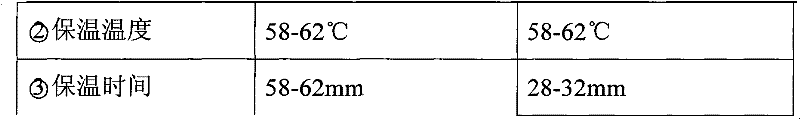

[0037] 1. A method for making gray yarn into colored yarn, the method comprising the following formulas and processes:

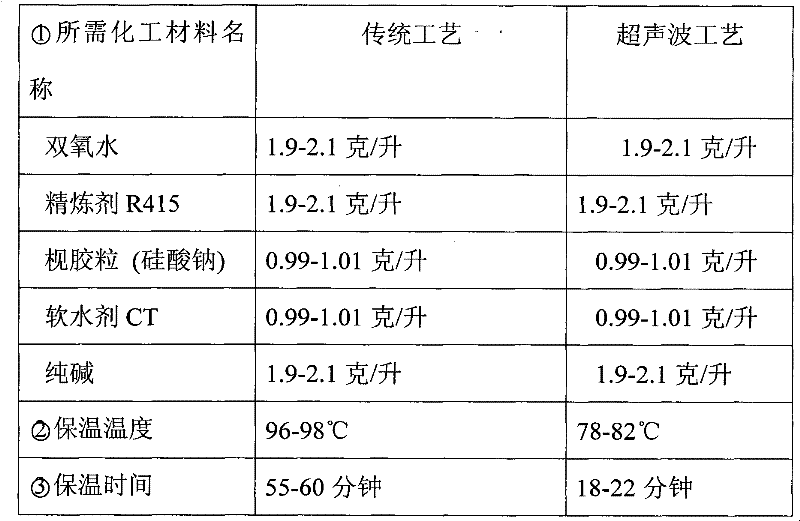

[0038] (1) Degreasing and bleaching formula and process

[0039] Degreasing and bleaching solution formula: In addition to water, it also contains the following substances: 2 g / L of hydrogen peroxide, 2 g / L of refining agent R415, 1 g / L of soap particles, 1 g / L of water softener CT and 2 g / liter of soda ash;

[0040] Degreasing and bleaching process: inject degreasing and bleaching solution equivalent to 15 times the weight of the gray yarn into the equipment with a frequency of 25K / HZ and a strength of 0.375W / CM 2 Put the gray yarn into the cabinet-type liquid flow hank yarn dyeing machine of the ultrasonic generating device, start the ultrasonic wave and the heating device, keep it warm at 80°C for 20 minutes, and degrease and bleach the above gray yarn;

[0041] (2) Washing process

[0042] Turn off the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com