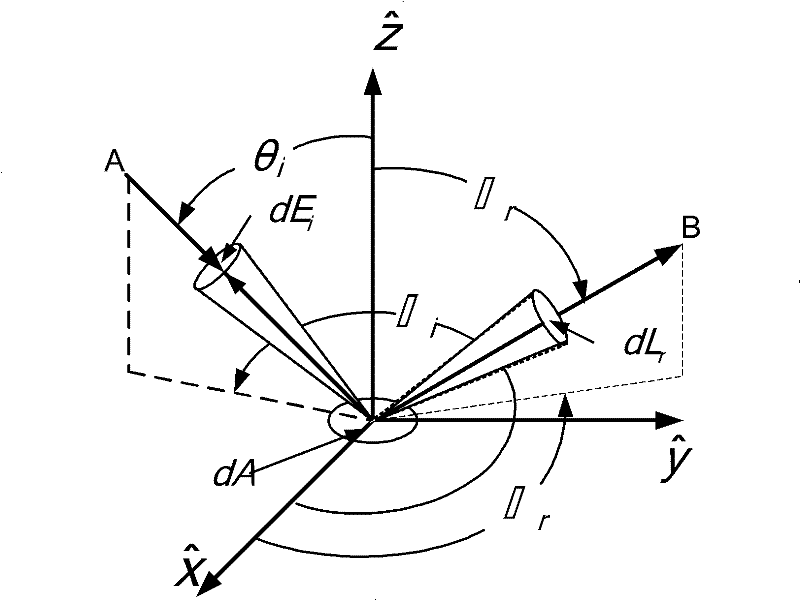

Measuring device of continuous spectrum bidirectional reflectance distribution function

A technology of bidirectional reflection distribution and measuring device, applied in the field of spectroscopy, can solve problems such as measuring continuous spectrum BRDF, etc., and achieve the effects of economical and feasible measuring device, simple device and high measuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

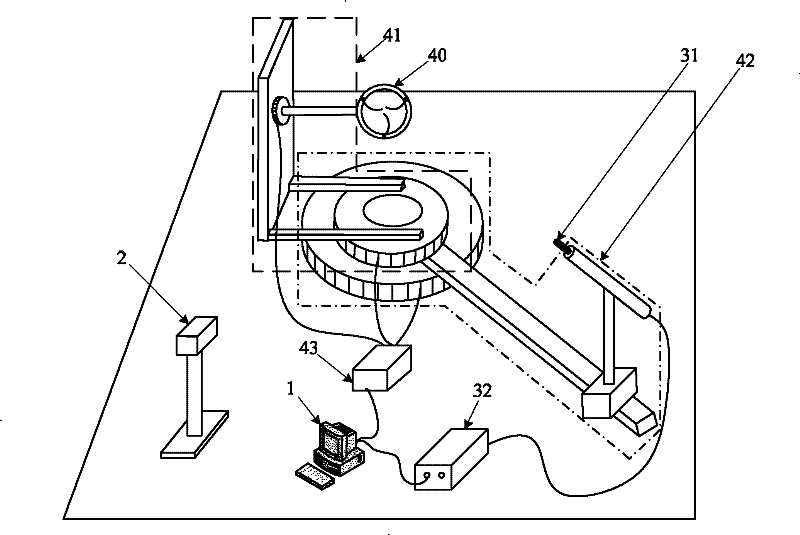

[0017] Specific implementation mode one: combine figure 2 Describe the present embodiment, the continuous spectrum bidirectional reflectance distribution function measuring device in the present embodiment, it comprises light source assembly 2, detector assembly, measuring frame assembly and control and data processing PC machine 1; Detector assembly comprises optical fiber probe 31 and spectrometer 32. The measuring frame assembly includes a sample ring 40, a sample horizontal and vertical rotation bracket 41, a detector position adjustment bracket 42 and a rotation controller 43; the sample ring 40 is installed on the sample horizontal and vertical rotation bracket 41, the The center point of the sample ring 40 is the center of rotation, and the horizontal and vertical rotation brackets 41 of the sample are used to drive the sample ring 40 to rotate on the horizontal plane and the vertical plane perpendicular to the horizontal plane with the center of rotation as the center ...

specific Embodiment approach 2

[0018] Specific implementation mode two: combination figure 2 and Figure 4 Describe this embodiment. The first difference between this embodiment and the specific embodiment is that the detector position adjustment bracket 42 includes a detector horizontal direction electric control rotation table 421, a guide rail 422, a slider 423, a detector pillar 424 and a detector adjustment frame 425 ; The detector horizontal direction electric control rotary table 421 is placed horizontally on the plane, and the detector horizontal direction electric control rotary table 421 is used to drive the detector to rotate on the horizontal plane; one end of the guide rail 422 is connected to the detector horizontal direction electric control rotary table 421 on the horizontal direction of the detector, and is linked with the electronically controlled rotary table 421 in the horizontal direction of the detector. A slider 423 is installed on the guide rail 422. The slider 423 is used to adjust...

specific Embodiment approach 3

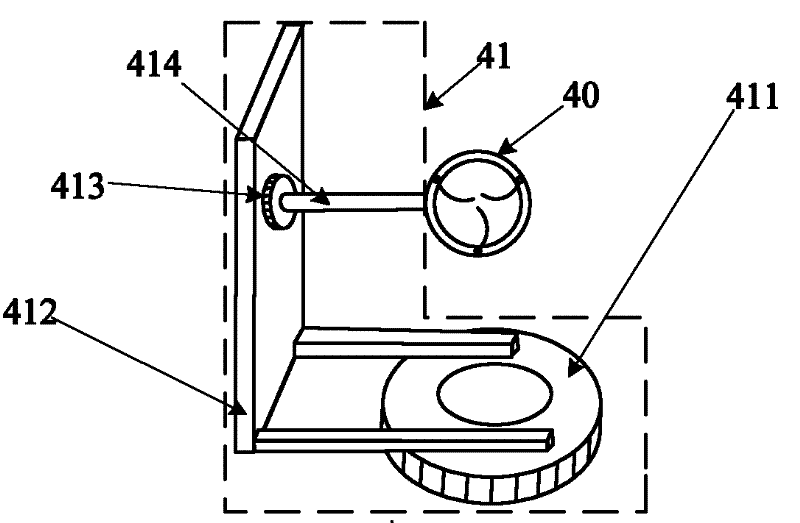

[0019] Specific implementation mode three: combination figure 2 and image 3 Describe this embodiment, the difference between this embodiment and specific embodiment 2 is that the sample horizontal and vertical direction rotation support 41 includes the sample horizontal direction electric control rotation table 411, the L-shaped connecting plate 412, the sample vertical direction electric control rotation table 413 and the sample holder 414; the sample horizontal direction electric control rotary table 411 is horizontally arranged on the upper part of the detector horizontal direction electric control rotary table 421, and the rotation axis of the sample horizontal direction electric control rotary table 411 coincides with the detector horizontal direction electric control rotary table 421 The electronically controlled rotary table 411 in the horizontal direction of the sample and the electronically controlled rotary table 421 in the horizontal direction of the detector rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com