Food quality testing system and method based on laser ultrasound erosion mechanism

A laser ultrasonic and quality inspection technology, applied in the generation of ultrasonic/sonic/infrasonic waves, etc., can solve problems affecting the health of workers, harsh testing environment, long testing time, etc., to achieve easy real-time online testing, without manual intervention, The effect of increasing excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

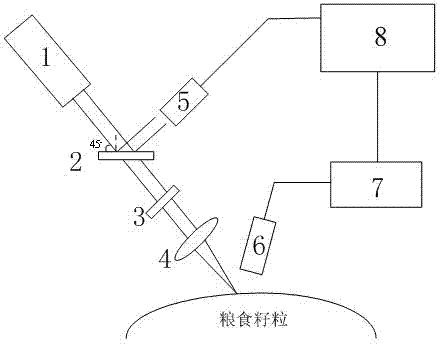

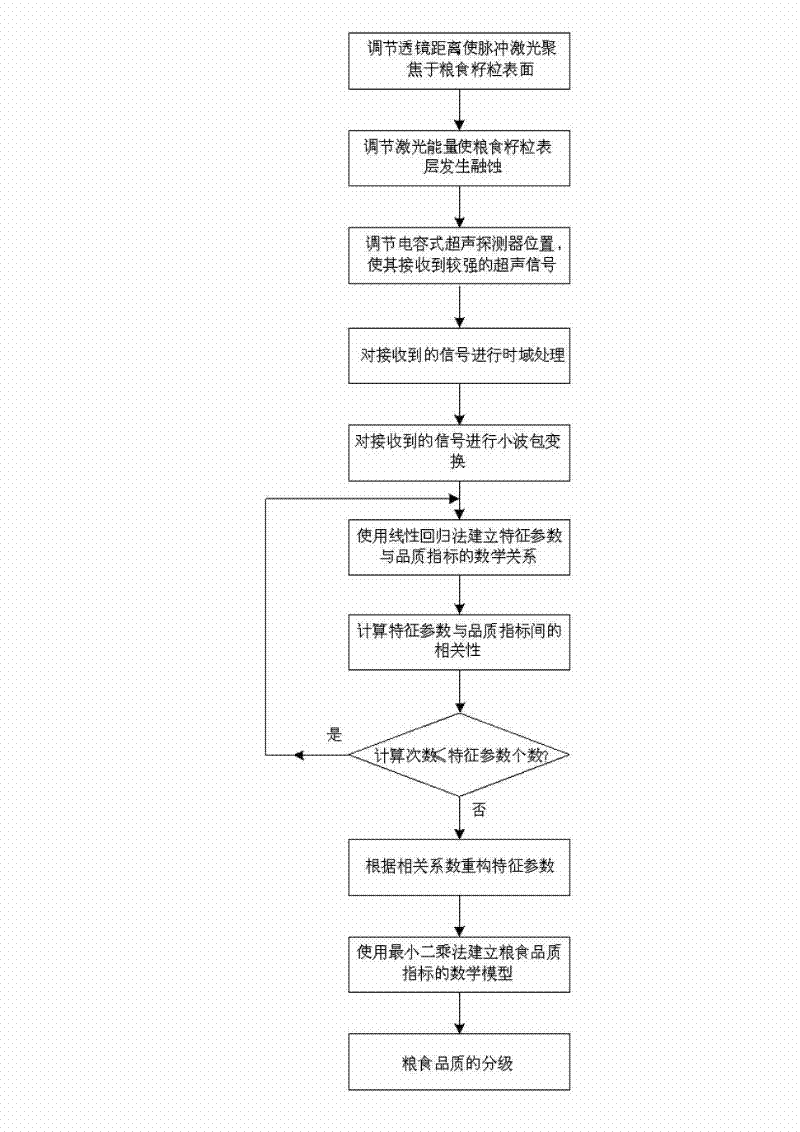

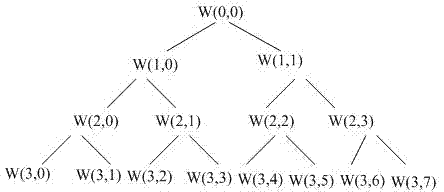

[0033] Such as figure 1 As shown, the food quality detection system based on the laser ultrasonic ablation mechanism of the present invention includes a laser 1, a beam splitter 2, an attenuation sheet 3, a lens 4, a photodiode 5, an amplifier 6, a computer 8 and an ultrasonic detector 7, and the ultrasonic detector The output end of device 7 is connected to the input end of amplifier 7, the output of amplifier 7 is connected to the input end of computer 7, amplifier 7, photodiode 5 are wired with computer 8 respectively, beam splitter 2, attenuation plate 3 and lens 4 are followed by Set on the optical axis of the laser 1, the beam splitter 2 is set horizontally, the optical axis of the beam emitted by the laser 1 and the beam splitter 2 form an incident angle of 45°, the attenuation sheet 3 and the lens 4 are perpendicular to the optical axis of the laser 1, and the photodiode 5 is placed on the optical axis of the light beam reflected by the beam splitter 2, and the photodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com