Solvent-free compound virtual simulation experimental system

A technology of virtual simulation and experimental system, applied in general control systems, control/regulation systems, simulators, etc., can solve the problems of infeasible, unrealizable, and difficult to meet the needs of CNC system manufacturers, saving teaching The effect of investment, improving the ability to deal with faults, saving production costs and test space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the drawings and embodiments.

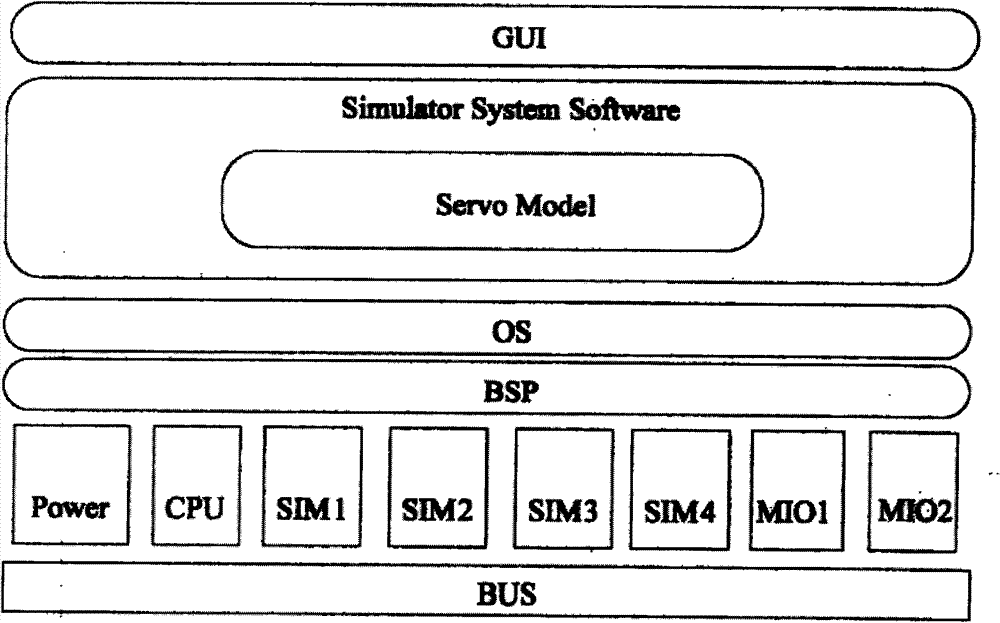

[0018] Such as figure 1 As shown, the system of the present invention is based on industrial PC technology, adopts an embedded Linux system, writes a driver, forms a board-level support package, builds an embedded operating system, and designs a servo motor virtual dedicated hardware-a servo virtual unit SIM, no solvent The electrical virtual unit of the compound machine is one I / O unit, the mathematical modeling of the common features of various servo motor models is extracted, the Linux driver is designed for the special hardware, the special graphical user interface, and finally the above is verified through the virtual simulation experiment system of the compound machine The various modules of the system are unified and integrated to provide users with a simple and flexible solvent-free composite virtual simulation experiment system.

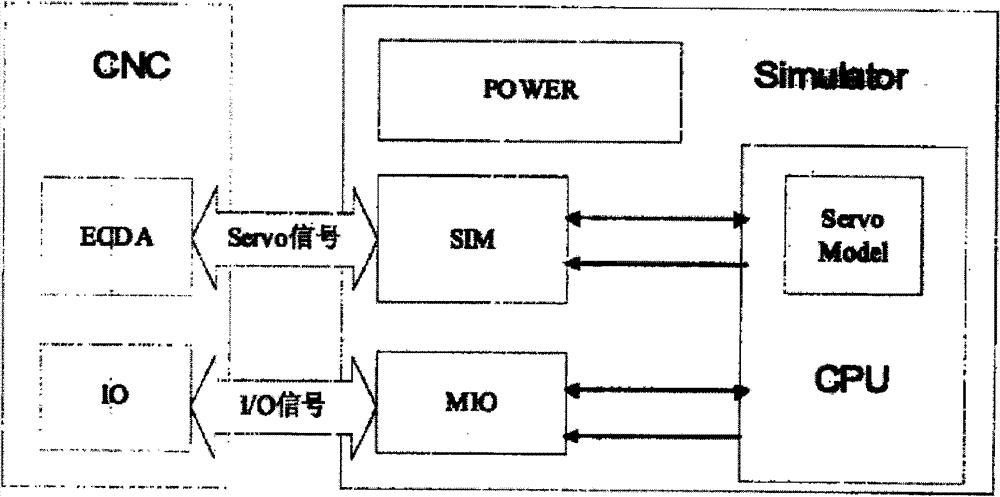

[0019] Such as figure 2 As sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com