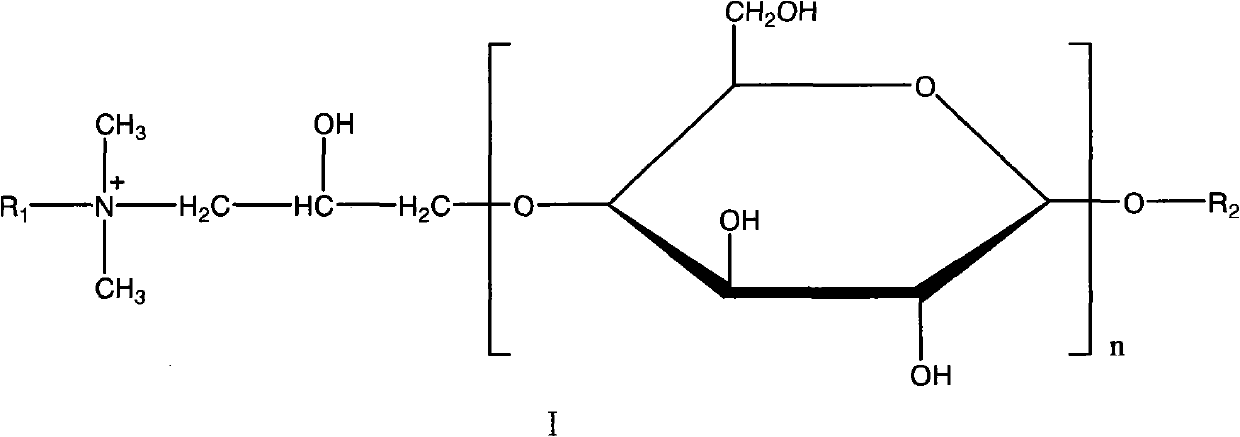

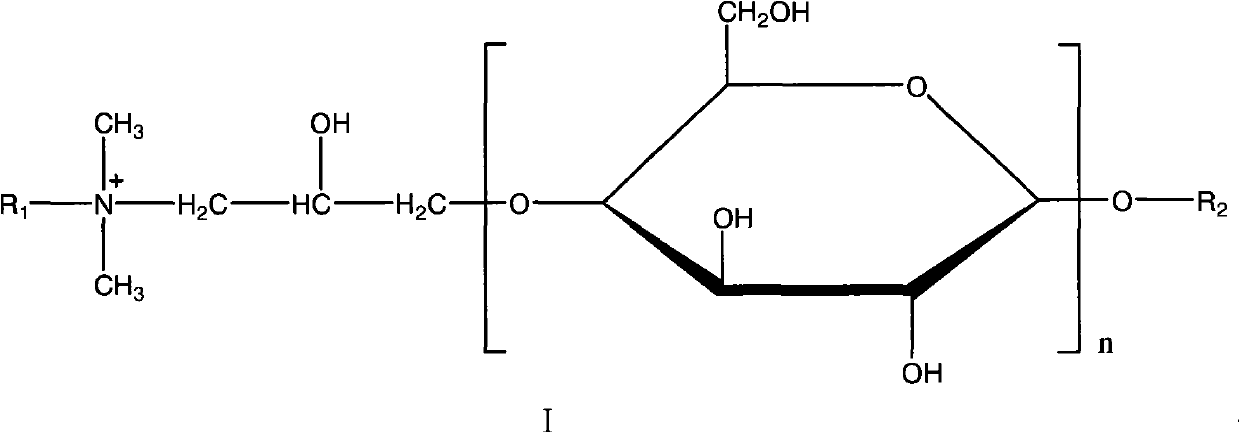

Method for preparing cationic alkyl polyglycoside surfactant

An alkyl polyglycoside and surfactant technology, which is applied in the field of preparation of cationic alkyl polyglycoside surfactants, can solve the problems of not fully realizing the excellent performance of the product, difficult to obtain monomers, difficult to control the reaction, etc. The effect of equipment investment and energy saving, low equipment requirements and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1: in the 250ml four-necked flask that has thermometer, stirrer, condenser tube, add the 50% dodecyl dimethyl tertiary amine hydrochloride aqueous solution of 99.81g, the epichlorohydrin of 11.10g Place in a separatory funnel, raise the temperature to 50°C, and slowly add epichlorohydrin dropwise while stirring. After 1 hour, the dropwise addition is completed, and the reaction is continued for 2 hours, cooled to room temperature, filtered with suction, washed with ethanol, and dried to obtain N-(3 -Chloro-2-hydroxypropyl)-N,N-dimethyl-N-dodecylammonium chloride cation intermediate.

[0024] In a 250ml four-neck flask with a thermometer, a stirrer, and a condenser tube, add 58.14g of N-(3-chloro-2-hydroxypropyl)-N,N-dimethyl-N-dodecyl Ammonium chloride cationic intermediate and 58.14g of deionized water, 55.46g of dodecyl polyglucoside with a degree of polymerization of 1.2 was made into a 60% solution and placed in a separatory funnel, heated to 60°C, and sl...

Embodiment 2

[0025] Embodiment 2: in the 250ml four-necked flask that has thermometer, stirrer, condenser, add the 50% tetradecyl dimethyl tertiary amine hydrochloride aqueous solution of 111.1g, the epichlorohydrin of 14.81g Place in a separatory funnel, raise the temperature to 60°C, and slowly add epichlorohydrin dropwise while stirring. After 2 hours, the dropwise addition is completed, continue the reaction for 3 hours, cool to room temperature, filter with suction, wash with ethanol, and dry to obtain N-(3 -Chloro-2-hydroxypropyl)-N,N-dimethyl-N-tetradecylammonium chloride cation intermediate.

[0026] In a 250ml four-necked flask with a thermometer, a stirrer, and a condenser, add 55.5g of N-(3-chloro-2-hydroxypropyl)-N,N-dimethyl-N-tetradecyl Ammonium chloride cationic intermediate and 55.5g of deionized water, 48.3g of tetradecyl polyglucoside with a degree of polymerization of 1.6 to form a 40% solution is placed in a separatory funnel, heated to 80°C, and slowly added dropwise w...

Embodiment 3

[0027] Embodiment 3: in the 250ml four-necked flask that has thermometer, stirrer, condenser, add the 50% hexadecyl dimethyl tertiary amine hydrochloride aqueous solution of 61.1g, the epichlorohydrin of 9.25g Place in a separatory funnel, raise the temperature to 80°C, and slowly add epichlorohydrin dropwise while stirring. After 1 hour, the dropwise addition is completed, and the reaction is continued for 2 hours, cooled to room temperature, filtered with suction, washed with ethanol, and dried to obtain N-(3 -Chloro-2-hydroxypropyl)-N,N-dimethyl-N-hexadecyl ammonium chloride cation intermediate.

[0028] In a 250ml four-neck flask with a thermometer, a stirrer, and a condenser, add 39.8g of N-(3-chloro-2-hydroxypropyl)-N,N-dimethyl-N-dodecyl Ammonium chloride cationic intermediate and 39.8g of deionized water, 65.5g of cetyl polyglucoside with a degree of polymerization of 2.4 to make a 30% solution is placed in a separatory funnel, the temperature is raised to 85°C, and sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com