Photovoltaic curtain wall and manufacturing method thereof

A curtain wall and photovoltaic technology, applied in the field of photovoltaic curtain wall and its production, can solve the problems of energy saving, heat preservation, and no good infrared blocking effect, and achieve good thermal insulation and sound insulation performance, reduce heat exchange, and reduce heat radiation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Photovoltaic curtain walls are integrated into buildings, also known as Building Integrated Photovoltaics (BIPV). In the existing BIPV buildings, most of the photovoltaic curtain walls are of five-layer laminated structure, and the photovoltaic curtain wall of the five-layer laminated structure is not good in terms of heat insulation and sound insulation; in addition, there is also a hollow photovoltaic curtain wall, so Although the above-mentioned hollow photovoltaic curtain wall has good heat insulation and sound insulation performance, it does not have a good infrared barrier effect, so the indoor and outdoor environments can still exchange heat through thermal radiation, which is not conducive to achieving the purpose of energy saving and heat preservation.

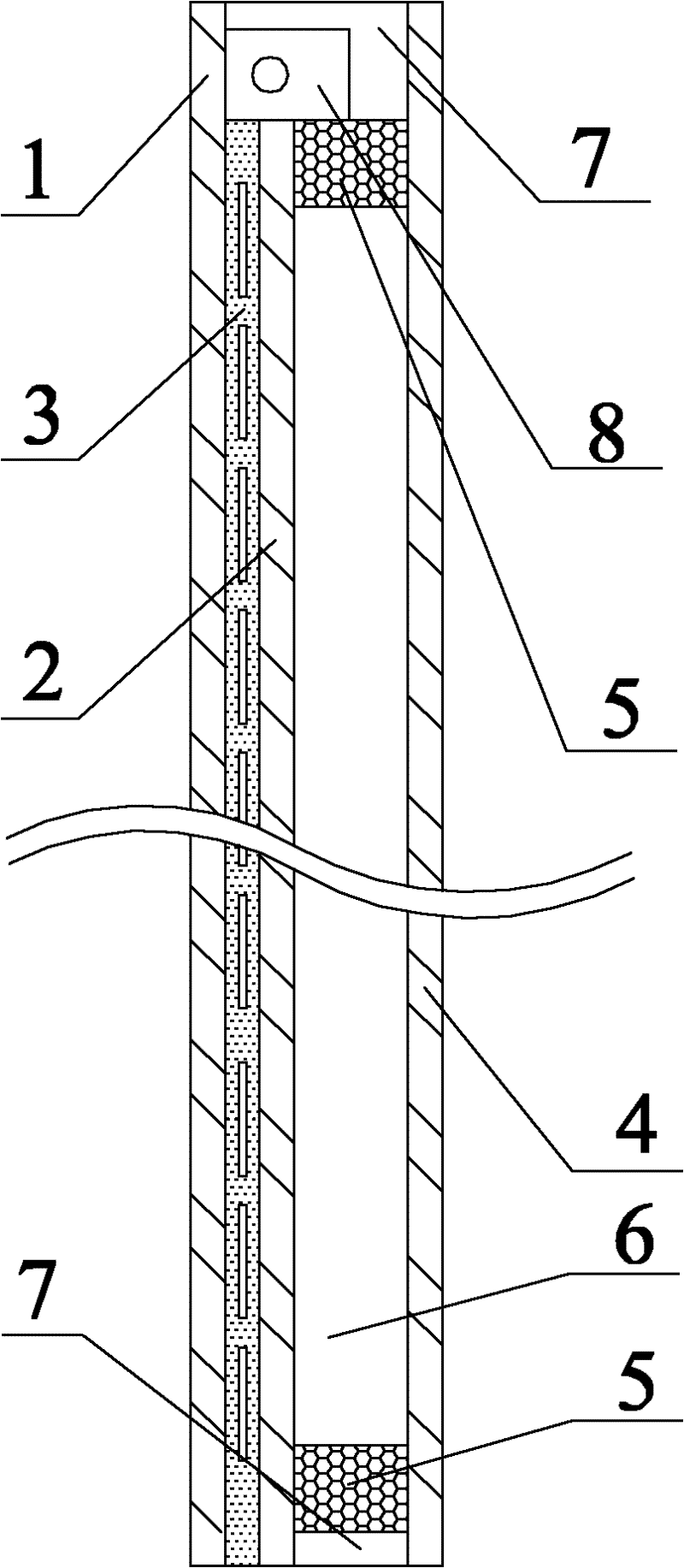

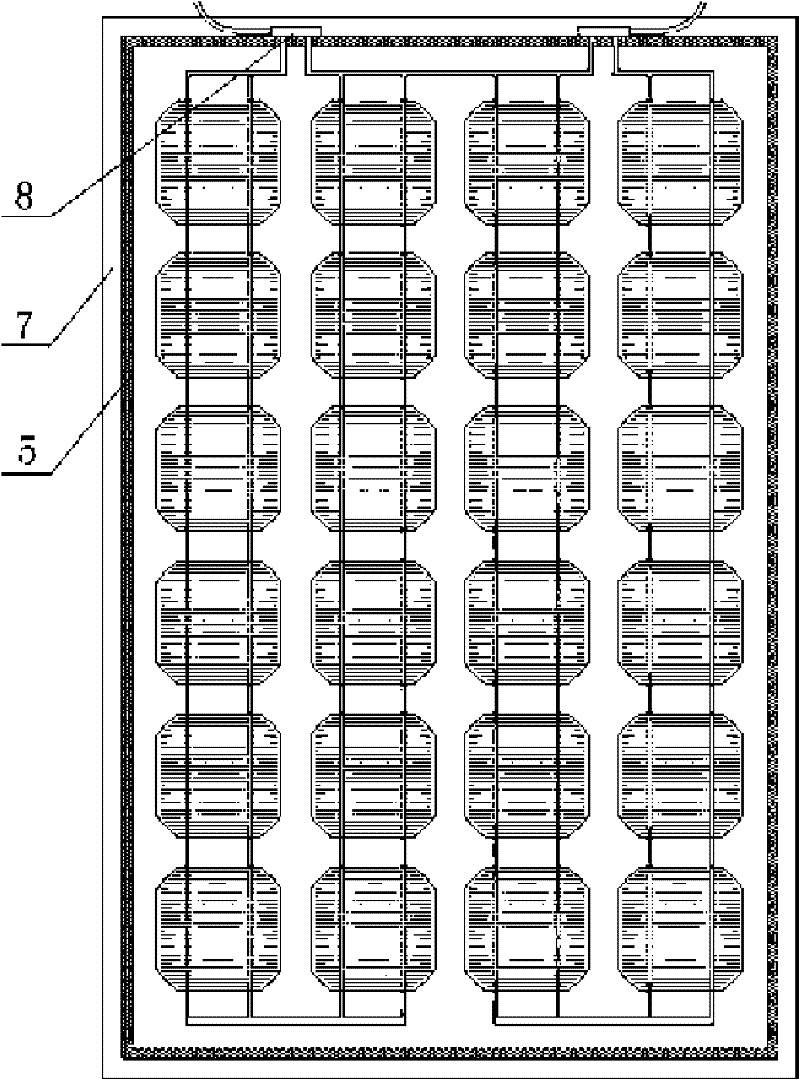

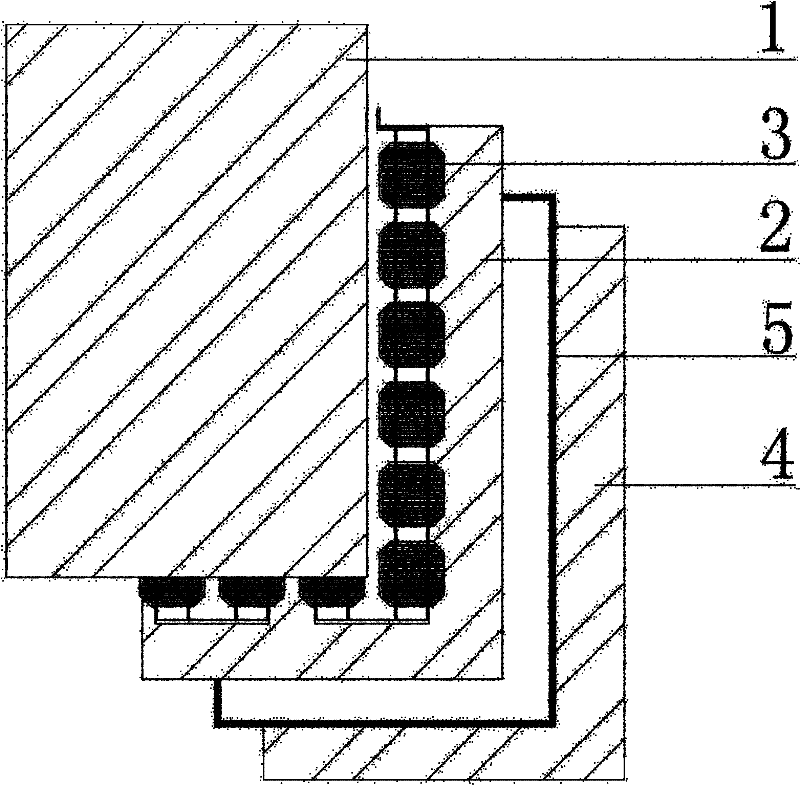

[0039] Based on this, the present invention provides a kind of photovoltaic curtain wall, with reference to figure 1 , the photovoltaic curtain wall includes: a double glass assembly and a laminated glass 4; th...

Embodiment 2

[0049] The present invention also provides a method for making a photovoltaic curtain wall, referring to Figure 4 , the method specifically includes the following steps:

[0050] Step S1: making a double glass assembly through a lamination process, the double glass assembly including top glass and bottom glass.

[0051] This step may further include steps S11-S15, specifically as follows:

[0052] Step S11: providing top glass.

[0053] The top glass is the first layer of glass for making double glass components. After the photovoltaic curtain wall is installed on the building, the top glass is the glass seen from the outside, and it can also be called the front of the photovoltaic curtain wall. Glass.

[0054] Step S12: Laying a first sealant on the top glass.

[0055] Step S13: laying solar battery sheets on the first sealant.

[0056] In this step, a solar cell layer is laid on the first sealant, and solar cell layers of different shapes or patterns can be laid accord...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com