Rotary flash drying system

A spin-flash evaporation and drying system technology, applied in the direction of drying solid materials, drying gas arrangement, drying, etc., can solve the problems of insufficient utilization of heat medium, unsuitable drying of viscous materials, large shape changes, etc., and achieve saving Steam consumption, good dust removal effect, and the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

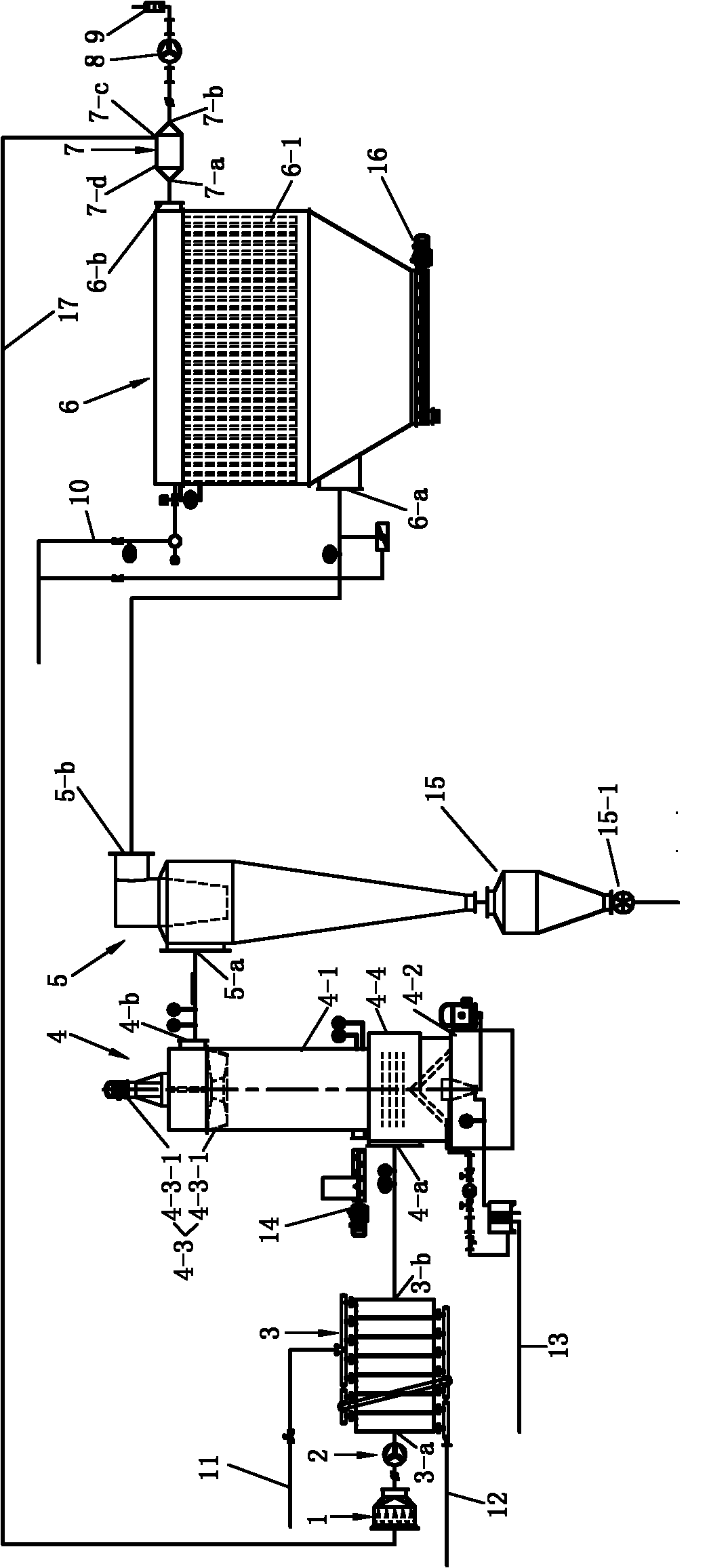

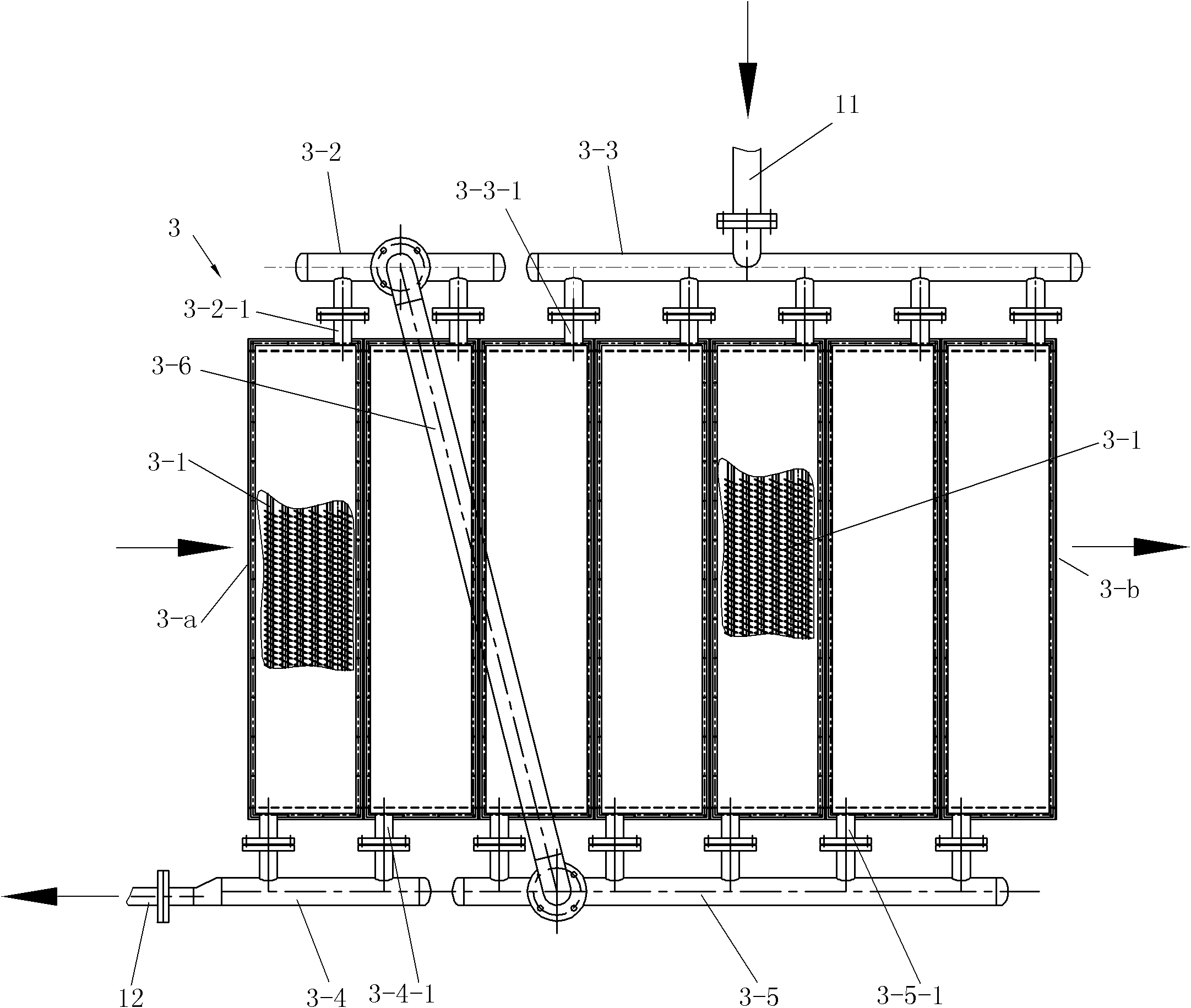

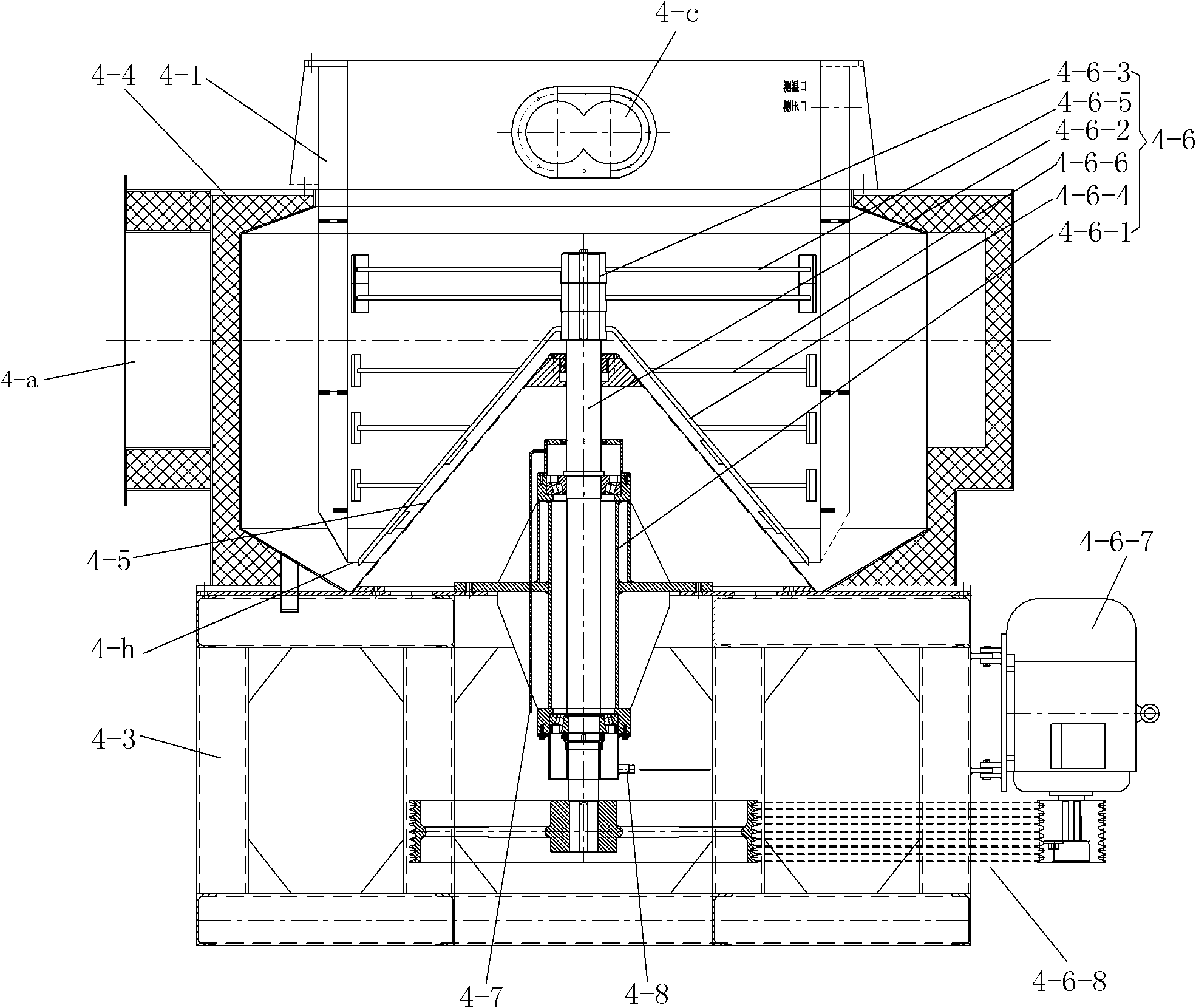

[0021] See the accompanying drawings, this embodiment has an air filter 1, blower 2, air heater 3, spin flash drying tower 4, cyclone separator 5, bag filter 6, air preheater 7, induced draft fan 8, muffler 9 and steam total supply pipe 11 and steam total return pipe 12. The feeding port 4-c of the flash drying tower 4 is provided with a feeder 14, the discharge port of the cyclone separator 5 is provided with a feed bin 15, and the discharge port of the feed bin 15 is provided with an unloader 15-1, and a bag filter 6 The discharge port is provided with a screw discharge device 16.

[0022] The air preheater 7 adopts a plate heat exchanger 7, and the hot plate heat exchanger is a new type of high-efficiency heat exchanger formed by stacking a series of metal sheets with a certain corrugated shape. Thin rectangular channels are formed between various plates, and heat is exchanged through half plates. Compared with conventional shell-and-tube heat exchangers, its heat transfer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com