Ultraviolet avalanche diode imaging array pixel, application method thereof and avalanche transistor imaging array

An imaging array and application method technology, applied in the direction of radiation control devices, etc., can solve the problems of high defect density, low yield, difficult manufacturing of GaN and AlGaN avalanche tubes, etc., and achieve the effect of increasing the photosensitive area and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Such as Figure 3A Shown is a schematic diagram of the imaging array pixel of the ultraviolet avalanche tube of the present invention.

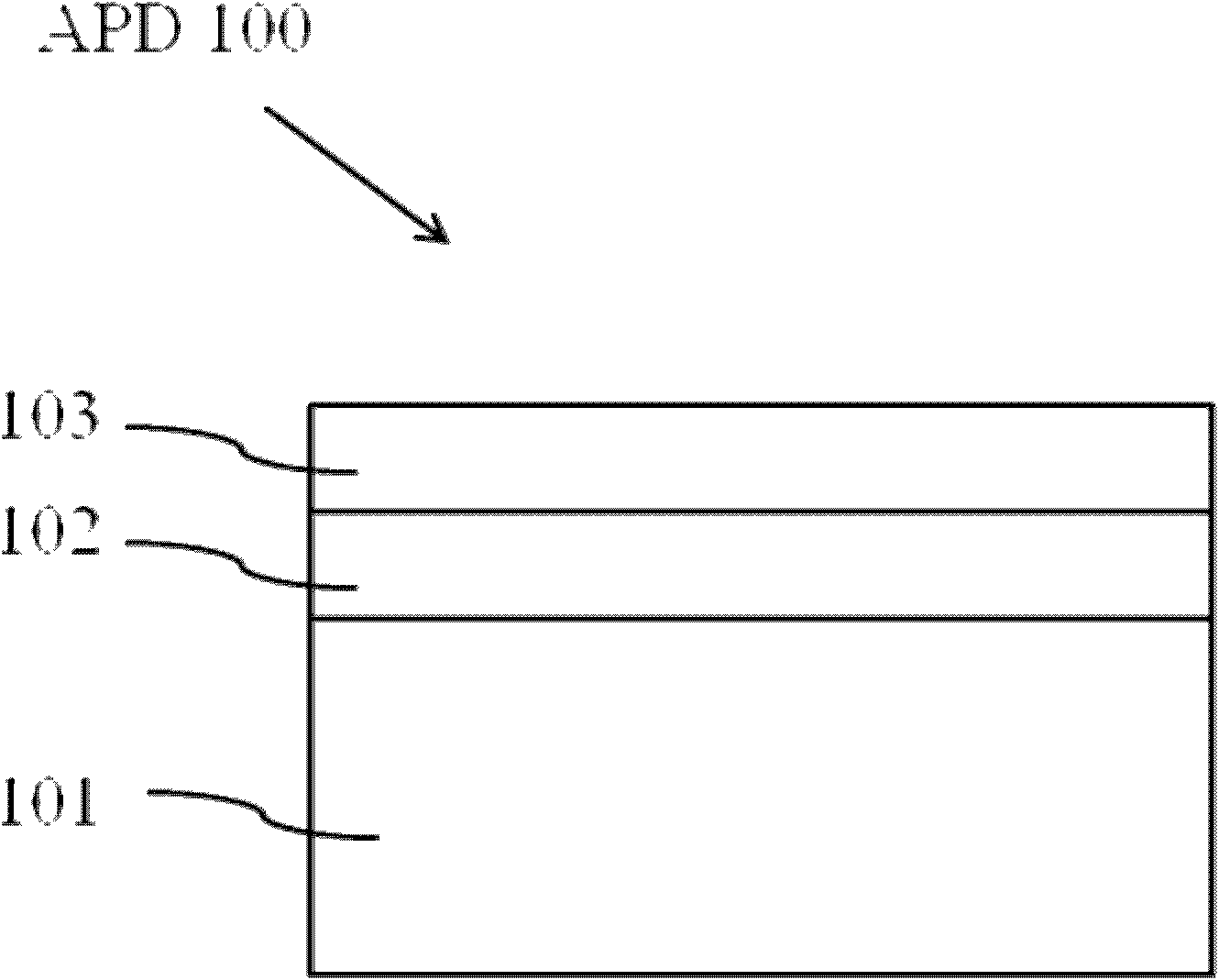

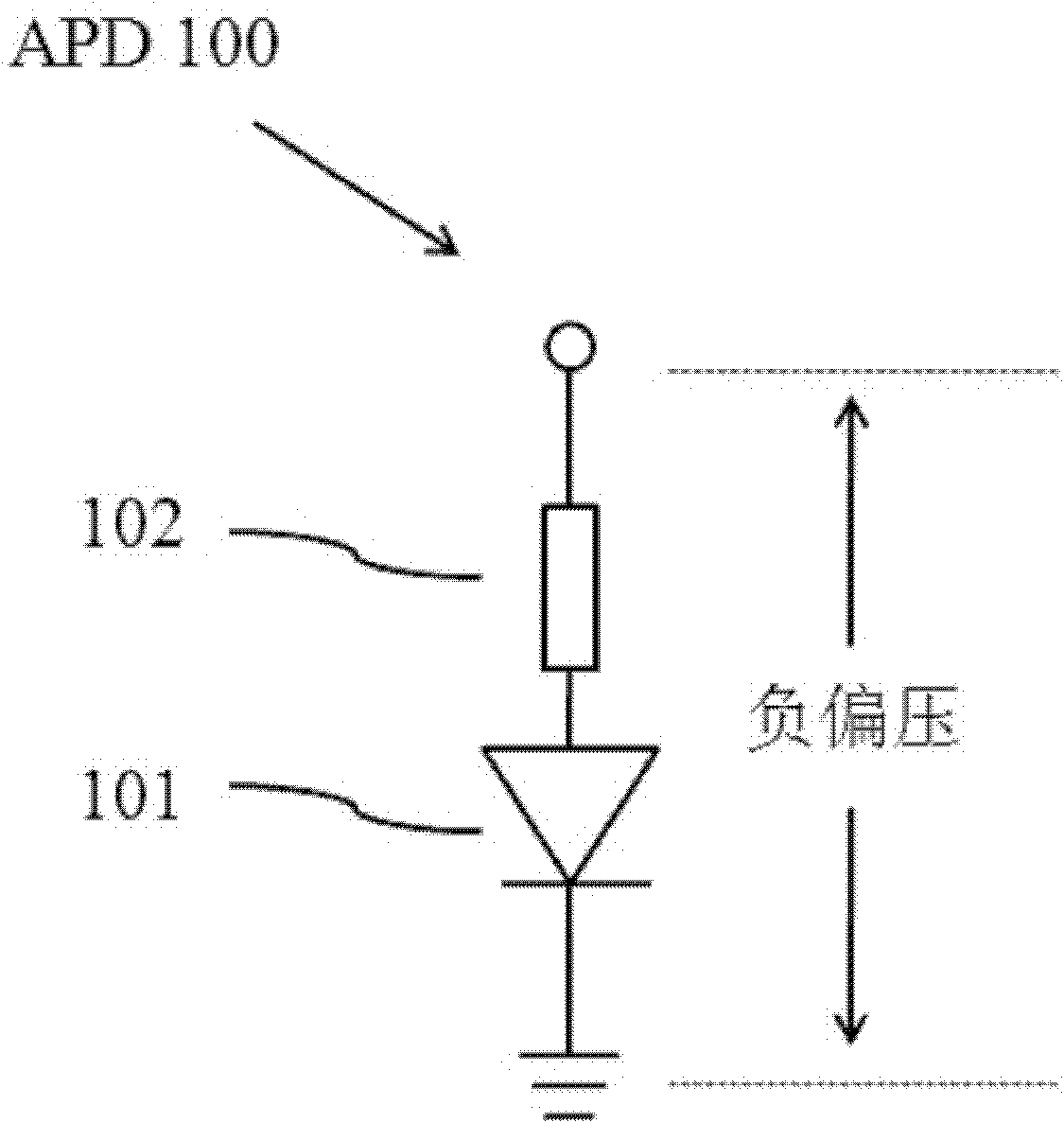

[0051] If the ultraviolet avalanche tube imaging array pixel UV-APD 300 is composed of a plurality of basic units UV-APD 200 (such as Figure 3B ) in parallel configuration, the radius of the UV-APD 200 can be 1 μm to 50 μm. exist Figure 3B Among them, we can form the substrate 201 from bottom to top. The substrate 201 can be made of materials such as SiC, sapphire, and silicon substrates, but the substrate is required to be transparent; the materials of the n-type semiconductor 202 and the p-type semiconductor 204 can be GaN, For materials such as AlN and AlGaN, n-type semiconductor 202 and p-type semiconductor 204 can be epitaxially grown by MOCVD, which also has a buffer layer, thereby reducing lattice dislocations in the material and reducing defect density; then etching the p-type semiconductor to expose Part of the n-type sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com