NPN-structure-based laser photovoltaic cell and preparation process thereof

A laser photovoltaic cell, photovoltaic cell technology, applied in photovoltaic power generation, sustainable manufacturing/processing, circuits, etc., can solve problems such as increasing manufacturing cost and increasing material growth time, reducing costs, saving process time, and reducing consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

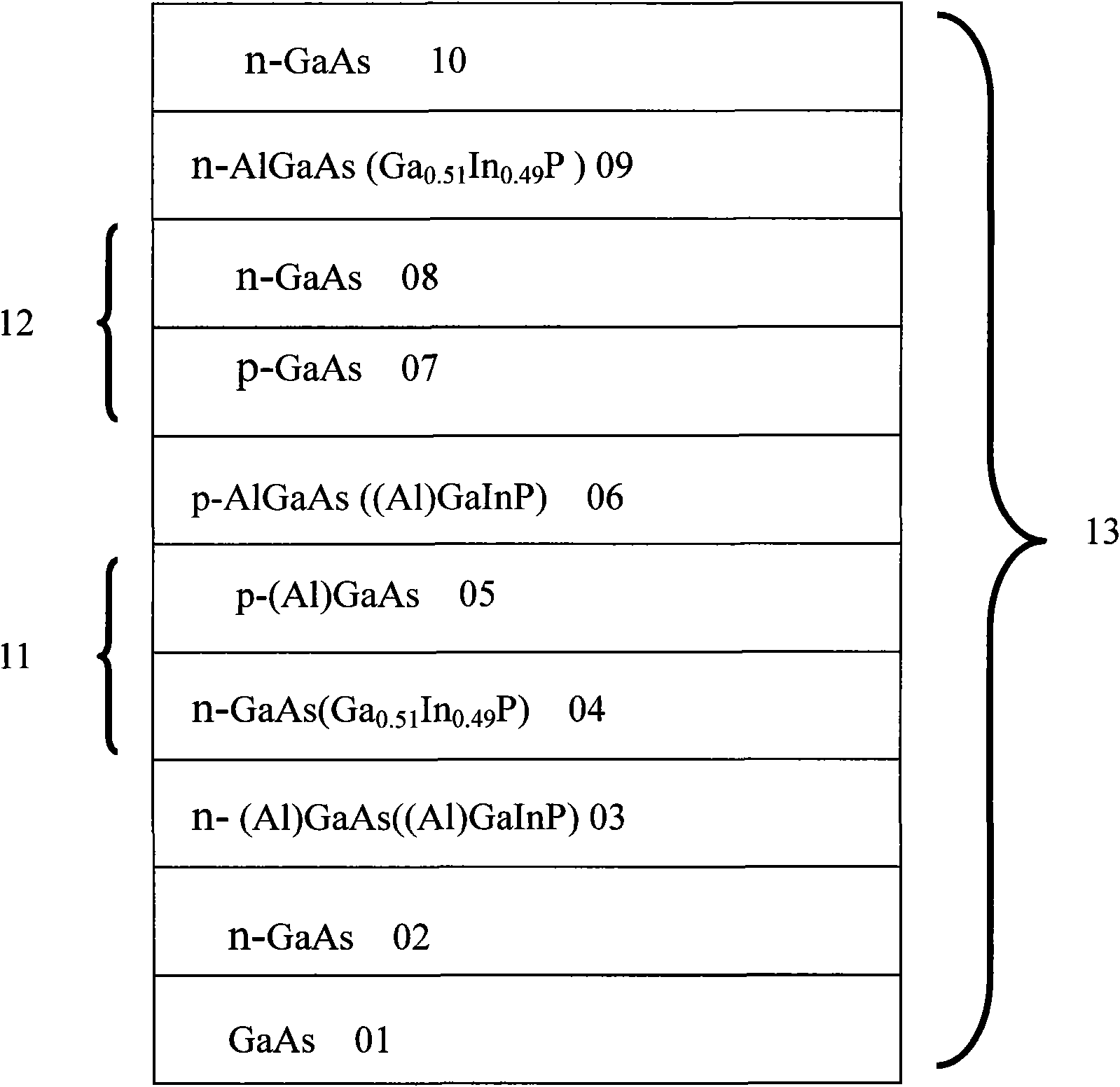

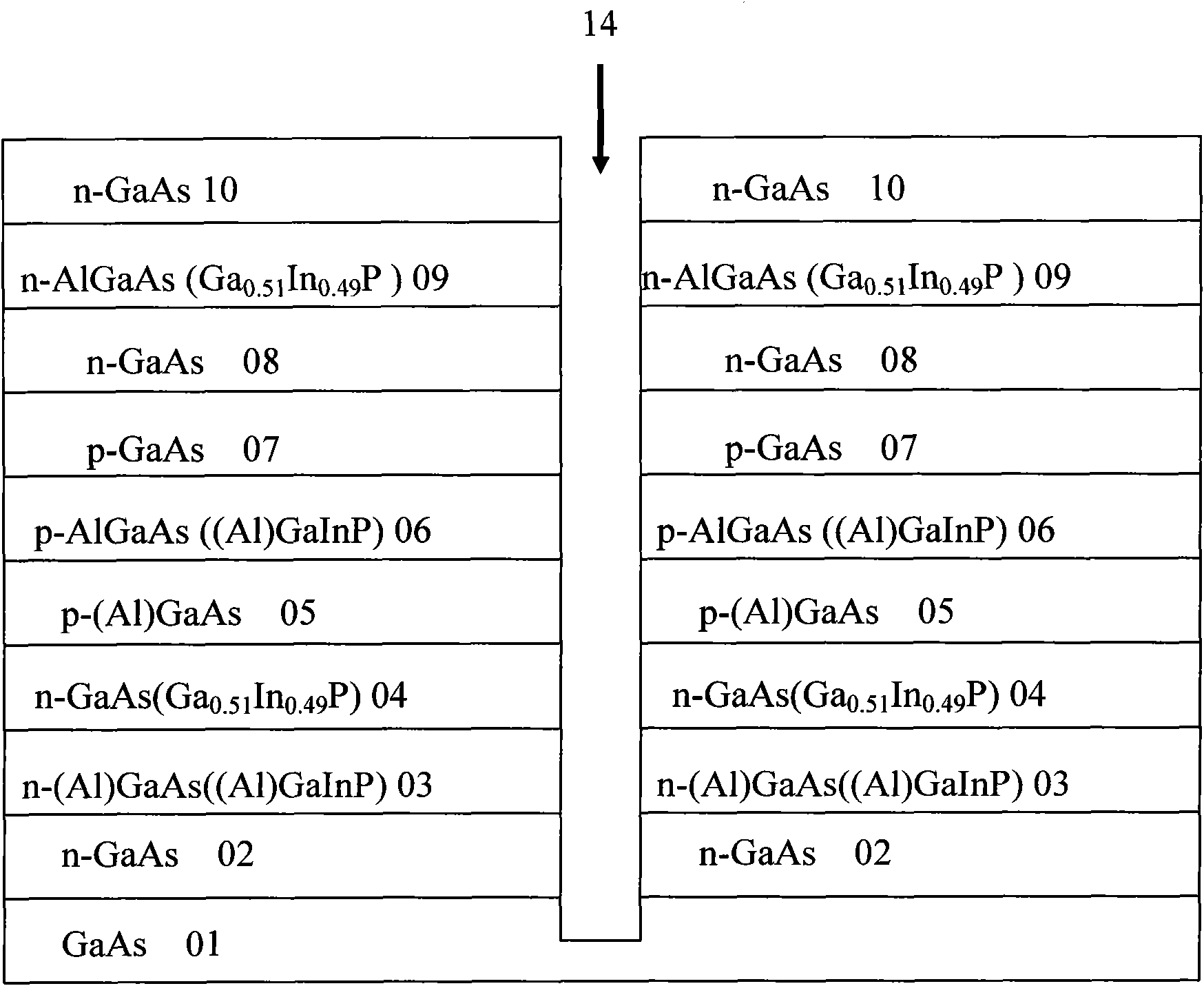

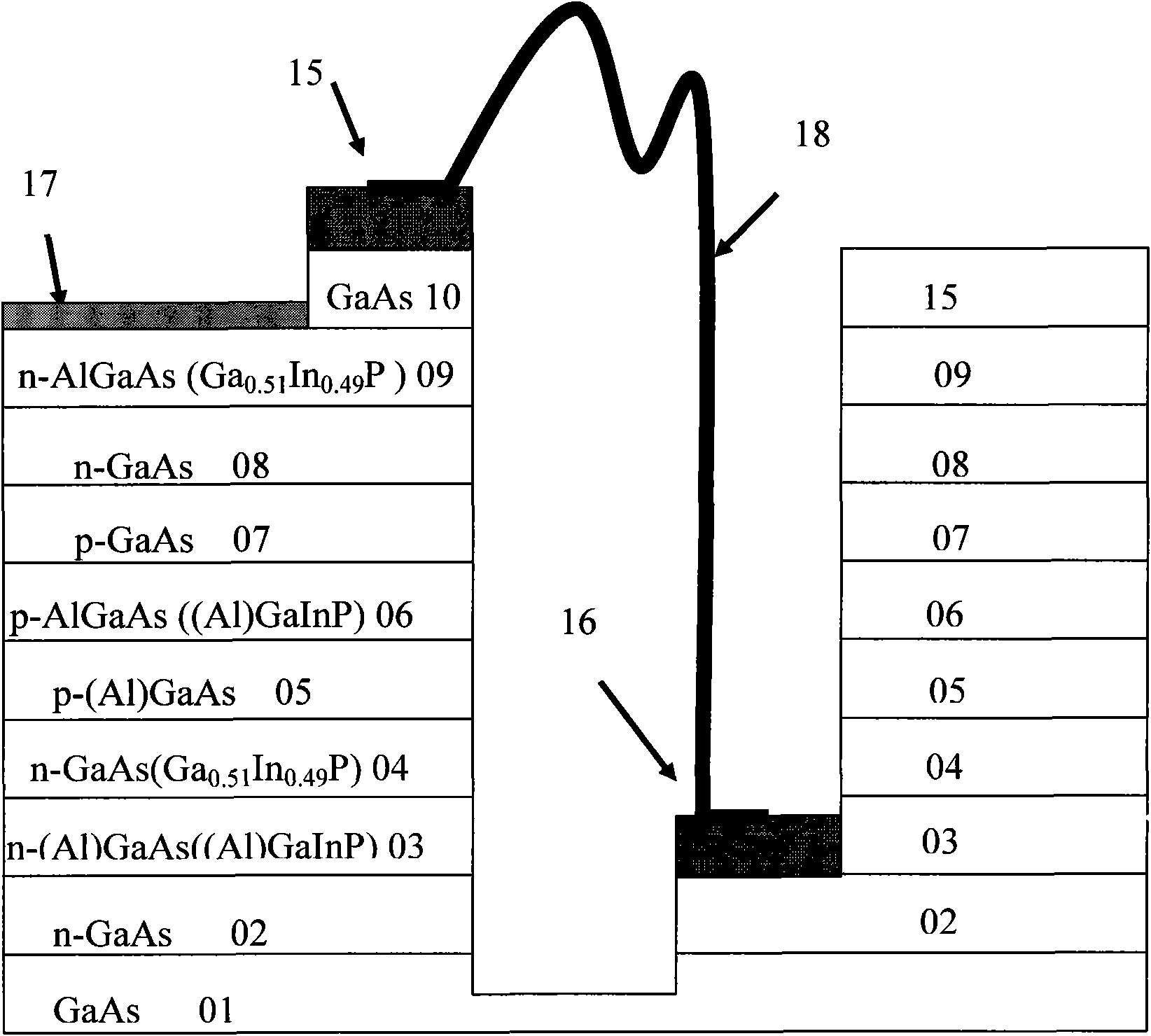

[0048] The aforementioned preparation method of the laser photovoltaic cell based on the NPN structure comprises the following steps:

[0049] (1) On the semi-insulating GaAs substrate, the N-type doping concentration is grown by epitaxial growth and other methods at 1×10 18 cm -3 The above GaAs conductive layer;

[0050] (2) On the N-type GaAs conductive layer, the doping concentration is grown at 1×10 18 cm -3 For the above N-type AlGaAs ((Al)GaInP) barrier layer, this step can also be omitted;

[0051] (3) On the above-mentioned barrier layer, the N-type doping concentration is grown at 1×10 19 cm -3 Above GaAs(Ga 0.51 In 0.49 P) layer, the re-growth doping concentration is 1×10 19 cm -3 The above P-type layer of (Al)GaAs forms a tunnel junction, and the thickness of the P-type and N-type regions is greater than 10nm;

[0052] (4) On the above-mentioned tunnel junction, the doping concentration is grown at 1×10 18 cm -3 The above P-type AlGaAs ((Al)GaInP) barrie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com