Selenylation furnace for treating and preparing CIGS (Copper Indium Gallium Diselenide) solar cell absorbing layer and manufacturing method thereof

A technology for solar cells and selenization furnaces, applied in coatings, circuits, electrical components, etc., can solve problems such as long processing cycle, high technical difficulty, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

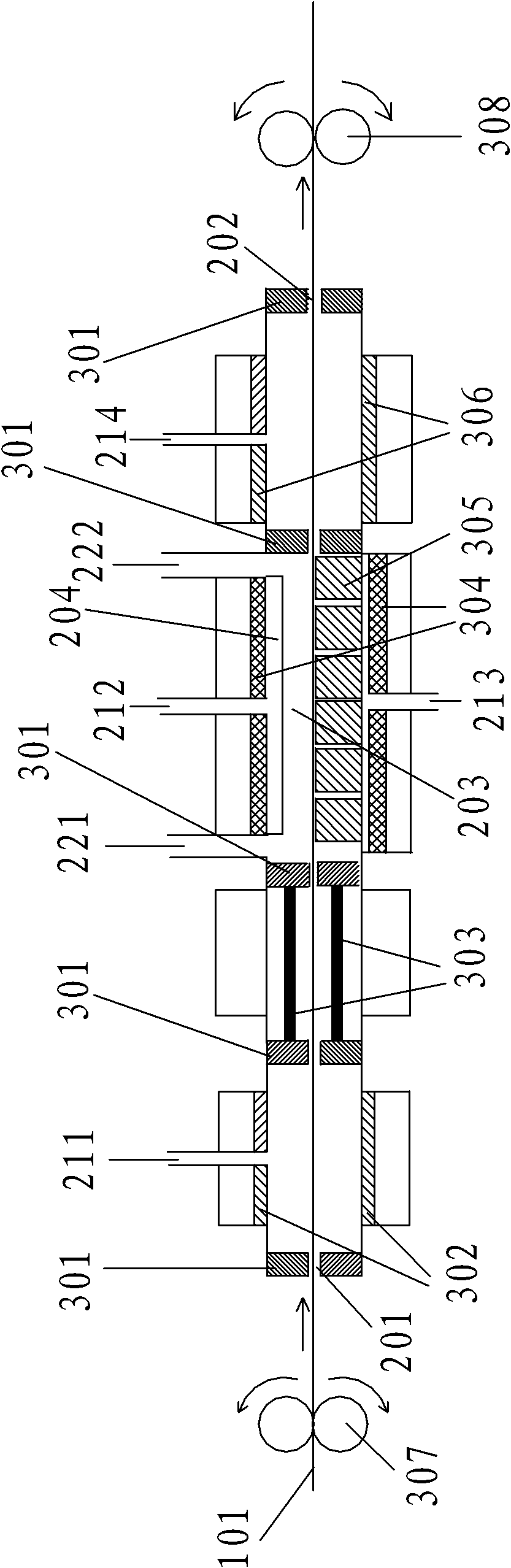

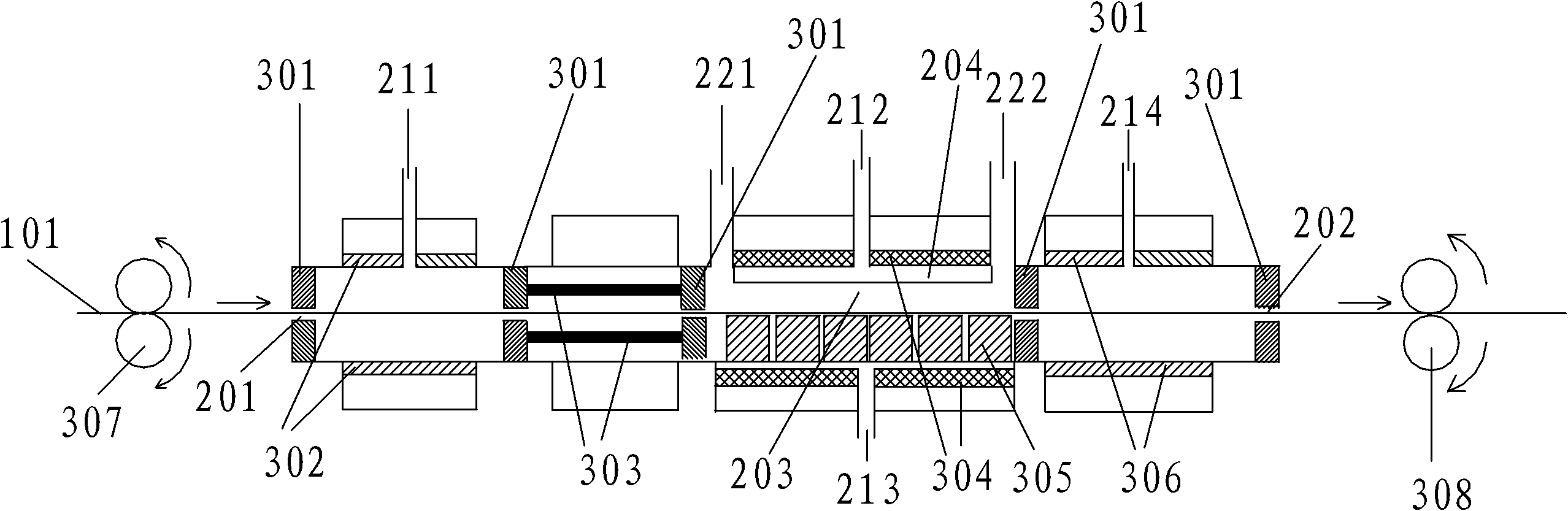

[0027] see figure 1 The main body of the selenization furnace of the present invention mainly consists of a transition section, a rapid heating section, a selenization reaction section and a cooling section. A slit formed by a baffle 301 is provided at the joint of the segments. The transition section, the selenization reaction section and the cooling section are provided with a transition section gas inlet pipe 211, a selenium vapor inlet 212, an air inlet pipe 213 for the selenization reaction section, and an air inlet pipe 214 for the cooling section, which communicate with the furnace chamber. The gas in the selenium vapor inlet 212 first enters the interlayer chamber formed by the interlayer 204 , and then passes into the reaction chamber 203 through the small through holes distributed irregularly on the interlayer 204 . A graphite pad 305 is provided at the lower part of the reaction chamber 203 , and the inert gas in the inlet pipe 213 of the selenization reaction sect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com