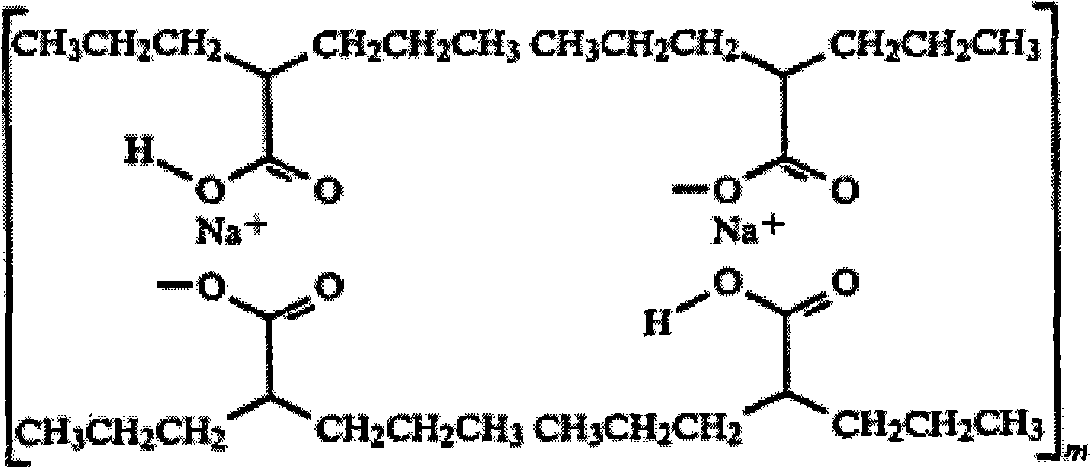

Stabilized divalproex sodium coated granules, preparation method and solid preparation thereof

A technology of divalproex sodium and coated granules, which is applied in the direction of medical preparations of non-active ingredients, pill delivery, and pharmaceutical formulations, which can solve the problem of increasing operating costs, which is not conducive to the work of preparation production personnel, divalproex sodium Instability in the storage process and other problems, to achieve the effect of good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

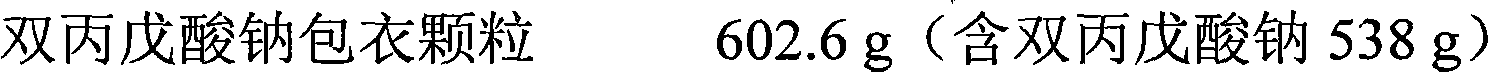

Embodiment 1

[0045] Divalproex sodium is pulverized to obtain 1 kg of powder whose particle size D (90) is 327 μm; 100 g of hypromellose (E5) is dissolved in 1900 g of purified water to prepare a solution of 5% concentration; 1 kg of pulverized divalproex Sodium valerate and 20g of micropowder silica gel are placed in the ENGER fluidized bed of the model WBF-III, and the mode of bottom spray coating is adopted, and the air inlet flow rate is set to 80m 3 / h, the inlet air temperature is 50°C, after the fluidized state is formed in the fluidized bed, the hypromellose solution is sprayed into the material surface of the fluidized bed through the peristaltic pump, the atomization pressure is 150kPa, and the peristaltic pump speed is 25rpm, after the hypromellose solution is sprayed, the air inlet temperature is raised to 65°C for drying, and when the drying weight loss of the material measured by the infrared moisture analyzer is ≤3.0%, the drying is stopped to obtain the hydroxypropyl methylc...

Embodiment 2

[0047] Divalproex sodium is pulverized to obtain 1kg particle diameter D (90) is the powder of 634 μm; 18g glyceryl monostearate, 60g triethyl citrate and 7.2g polysorbate 80 are dissolved in 655g purified water, then add to 2000g In L 30D-55, stir evenly to obtain a coating solution with a solid content of 25%; place 1 kg of pulverized divalproex sodium in an ENGER fluidized bed model WBF-III, and use top spray coating mode, Set the air intake flow rate to 80m 3 / h, the air inlet temperature is 50°C, after forming a fluidized state in the fluidized bed, the coating solution is sprayed into the material surface of the fluidized bed through a peristaltic pump, the atomization pressure is 200-250kPa, and the peristaltic pump speed is 20-50rpm , after the coating solution is sprayed, the air inlet temperature is increased to 65°C, and dried, and the drying is stopped when the drying weight loss of the material measured by the infrared moisture analyzer is ≤3.0%, and the coated ...

Embodiment 3

[0049] Divalproex sodium is pulverized to obtain 200g of a powder whose particle size D (90) is 32 μm; 200 g of hydroxypropyl cellulose (EF) is dissolved in 3800 g of purified water to prepare a solution of 5% concentration; 200 g of pulverized divalproex Sodium bicarbonate is dispersed in the solution of hydroxypropyl cellulose, spray-dried in BUCHI-290 spray dryer, the air flow rate is 100m 3 / h, the air inlet temperature is 125°C, the air outlet temperature is 50°C, the spray rate is 25%, the suction power is 100%, and the air pressure is 85psi to obtain the hyprolose-coated granules of divalproex sodium. The bulk density of the sodium-coated particles is 0.273 g / ml, the particle size D(90)=82 μm, and has good fluidity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com