Energy-efficient spring reinforced shot blast machine

An energy-saving, shot blasting machine technology, applied in abrasive jet machine tools, abrasives, metal processing equipment, etc., can solve the problems of high power consumption, many mechanical transmissions, easy to fail, etc., to achieve low power consumption and good interchangeability , the effect of reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

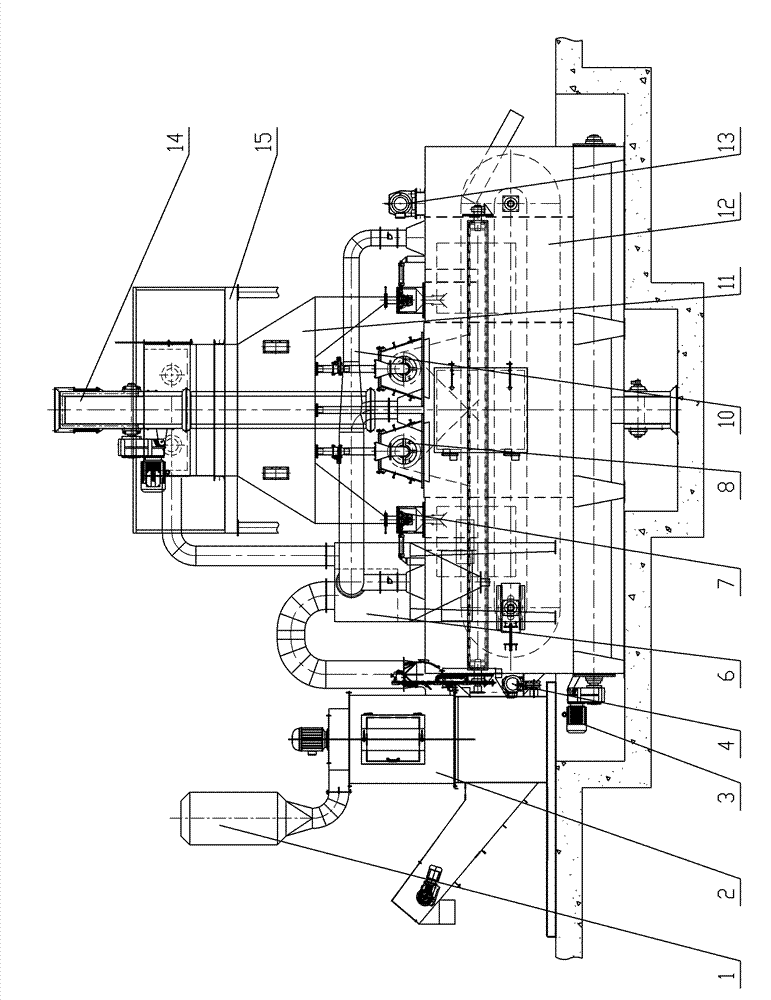

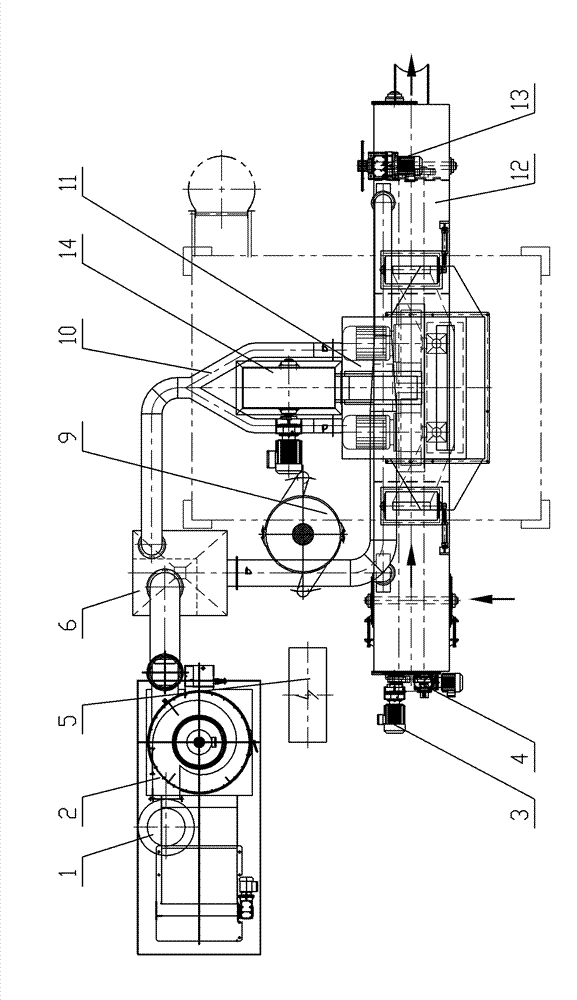

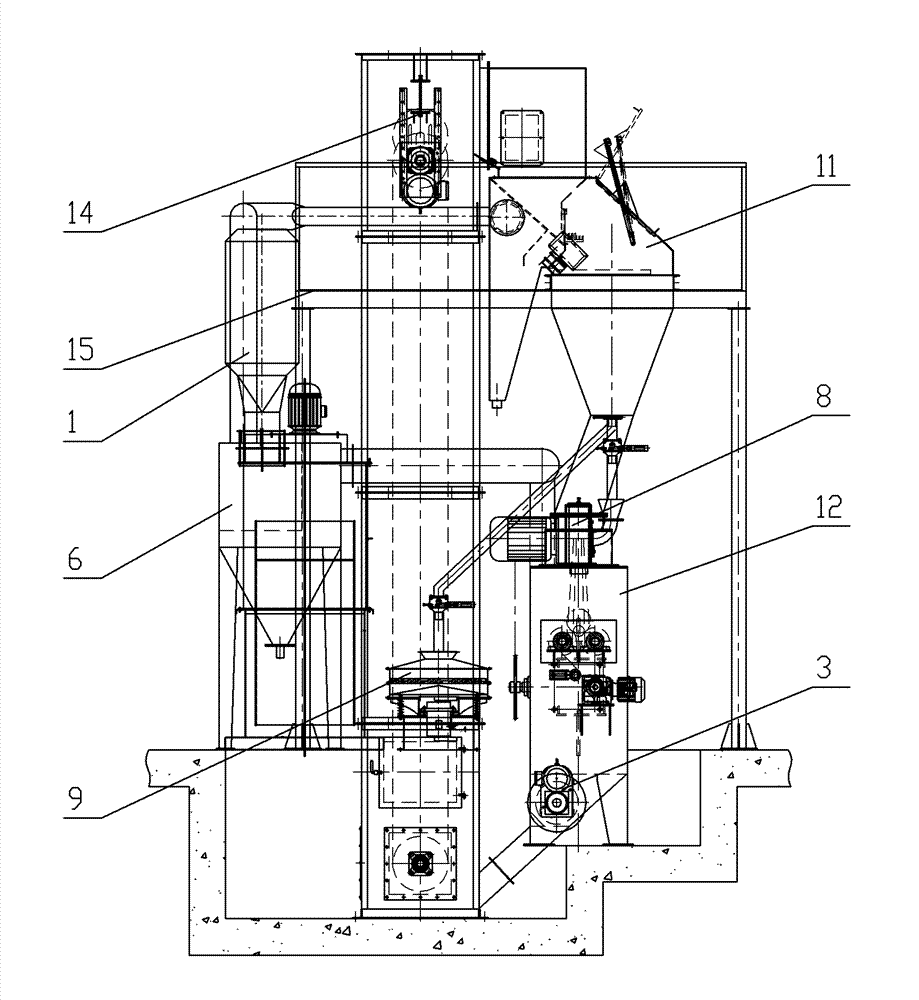

[0040] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0041] Figure 1 to Figure 25 Including muffler 1, dust collector and fan 2, screw conveyor 3, workpiece rotating mechanism 4, electrical system 5, settling chamber 6, steel shot flow curtain sealing device 7, shot blasting machine 8, vibrating screening machine 9, wind Pipe 10, steel shot sorter 11, shot blasting chamber 12, workpiece conveying mechanism 13, bucket elevator 14, maintenance platform 15, first bearing seat 16, driven sprocket 17, first roller chain 18, Drive sprocket 19, the first reduction motor 20, the first motor base 21, the roller 22, the first tension mechanism 23, the second tension mechanism 24, driven shaft 25, ring chain 26, lever seat 27, dial Rod 28, the second reduction motor 29, the second motor seat 30, the second bearing seat 31, the driving shaft 32, the ring sprocket 33, the driven roller sprocket 34, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com