Method for purifying N-methyl pyrrolidone and gamma-butyrolactone

A technology of methyl pyrrolidone and a purification method, which is applied in the field of purification of N-methyl pyrrolidone and γ-butyrolactone, can solve the problem that the content of metal ions and the number of particles cannot meet the requirements, restricting the development of high-purity organic electronic chemicals, The problem of high content of solid dust particles has achieved the effect of good market prospects, less environmental pollution and easy control of conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

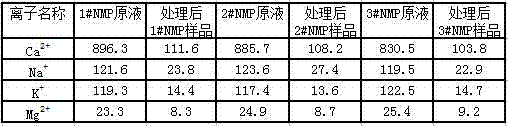

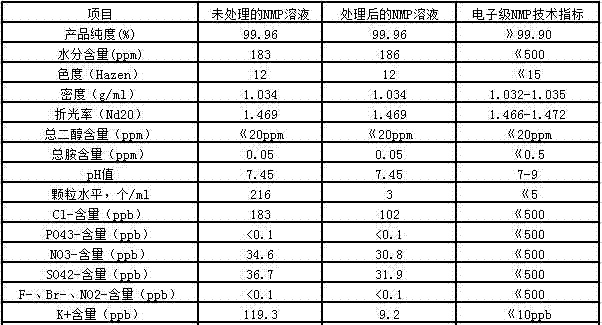

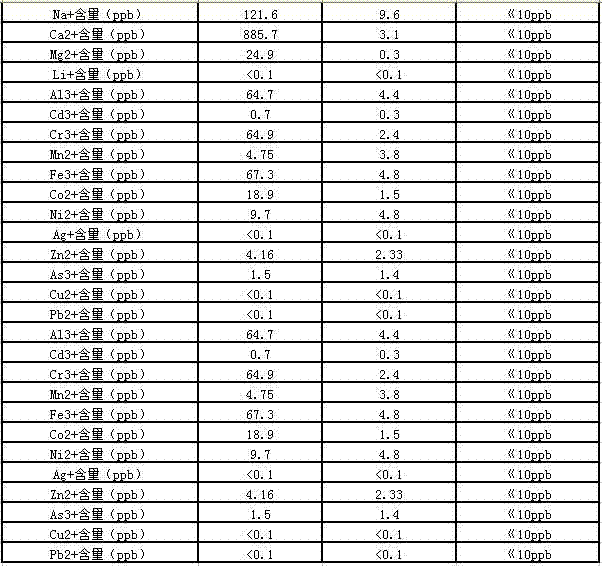

Examples

Embodiment

[0031] 1. Take polystyrene-divinylbenzene type anionic resin and polystyrene-divinylbenzene type cationic resin, soak them in deionized water for 12 hours respectively (the soaking time here can be 12-36 hours), filter out the water, and then Under stirring conditions, soak the two resins with 4% HCl solution (premium pure) for 2 hours respectively, and then soak the two resins with 4% NaOH solution (premium pure) for 2 hours respectively, and finally Wash with ultra-pure water to neutrality; repeat the above operation twice; then soak the obtained anion resin with 4% carbonic acid solution (premium pure) with a mass fraction of 4% under stirring conditions for 6 hours, and use a 4% mass fraction of ammonia solution (Premium pure) Soak the obtained cationic resin for 5 hours, then rinse the two resins with deionized water to neutrality, continue to rinse for 2 hours, and drain the water. In this step, the mass fractions of the HCl solution, the NaOH solution, the carbonic acid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com