Method for recycling traditional chromium residue

A recycling and chromium slag technology, applied in the field of traditional chromium slag recycling, can solve the problems of high cost, small processing capacity and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

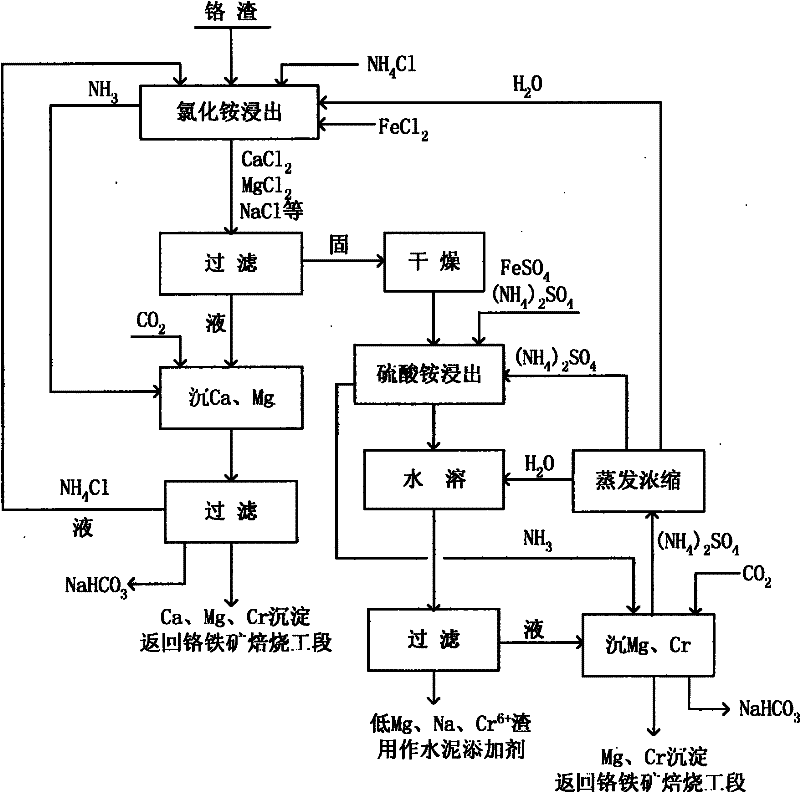

Method used

Image

Examples

Embodiment 1

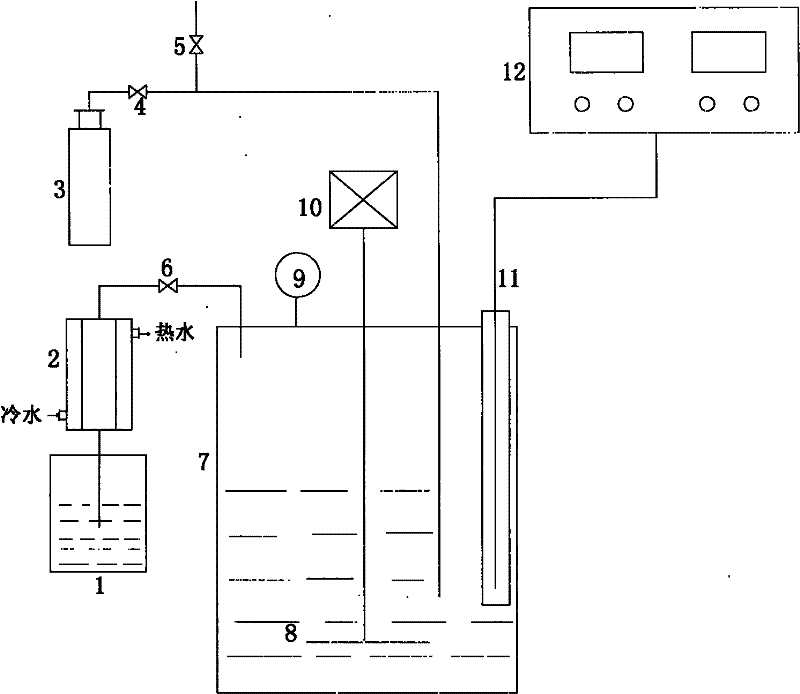

[0060] See figure 2 , the device is a schematic diagram of the main reaction device for leaching traditional chromium slag with ammonium chloride. The main component is an electric heating pressure reactor 7 (made of stainless steel, with an effective volume of 2L, the lid of which is detachable, fastened by bolts, and can be sealed to withstand the highest pressure. 10MPa).

[0061] On the outside of the lid of the electric heating pressure reaction kettle 7, a pressure gauge 9 is installed to show the pressure in the kettle; a thermocouple inserted into the bottom of the electric heating pressure reaction kettle to control the temperature in the electric heating pressure reaction kettle 11. It is connected to the program temperature controller 12 connected to the power supply outside the electric heating pressure reactor; a stirring blade 8 is arranged at the center of the inner bottom of the electric heating pressure reactor, and the stirring blade is connected to the elec...

Embodiment 2

[0075] Adopt the method and device of embodiment 1, just different reaction conditions are:

[0076] 1. Ammonium chloride leaching:

[0077] Weigh 100g of traditional chromium slag (passed through a 100-mesh sieve after being crushed and ground, and the composition is shown in Table 1), weigh 240g of ammonium chloride and 20g of ferrous chloride tetrahydrate, and measure 445ml of deionized water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com