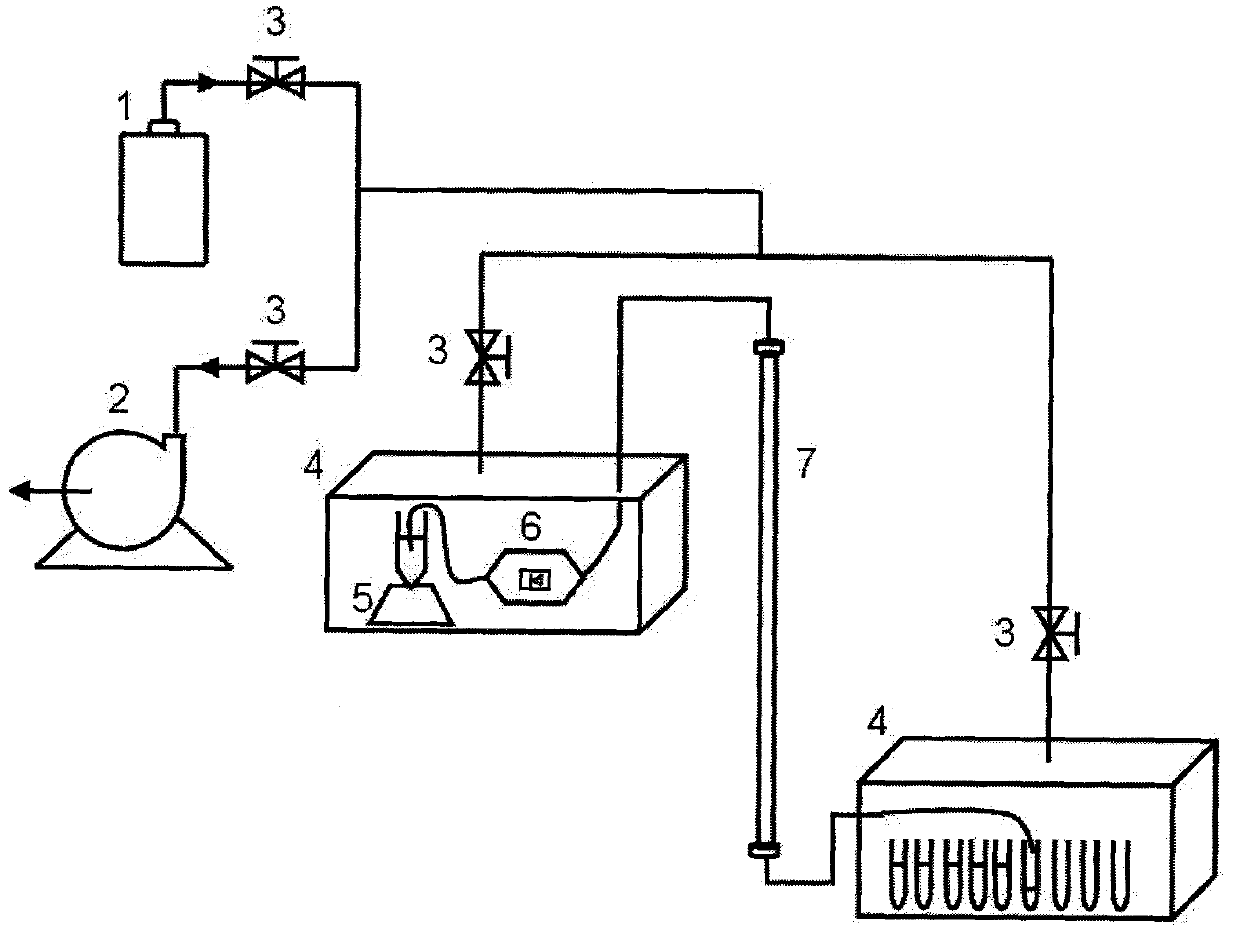

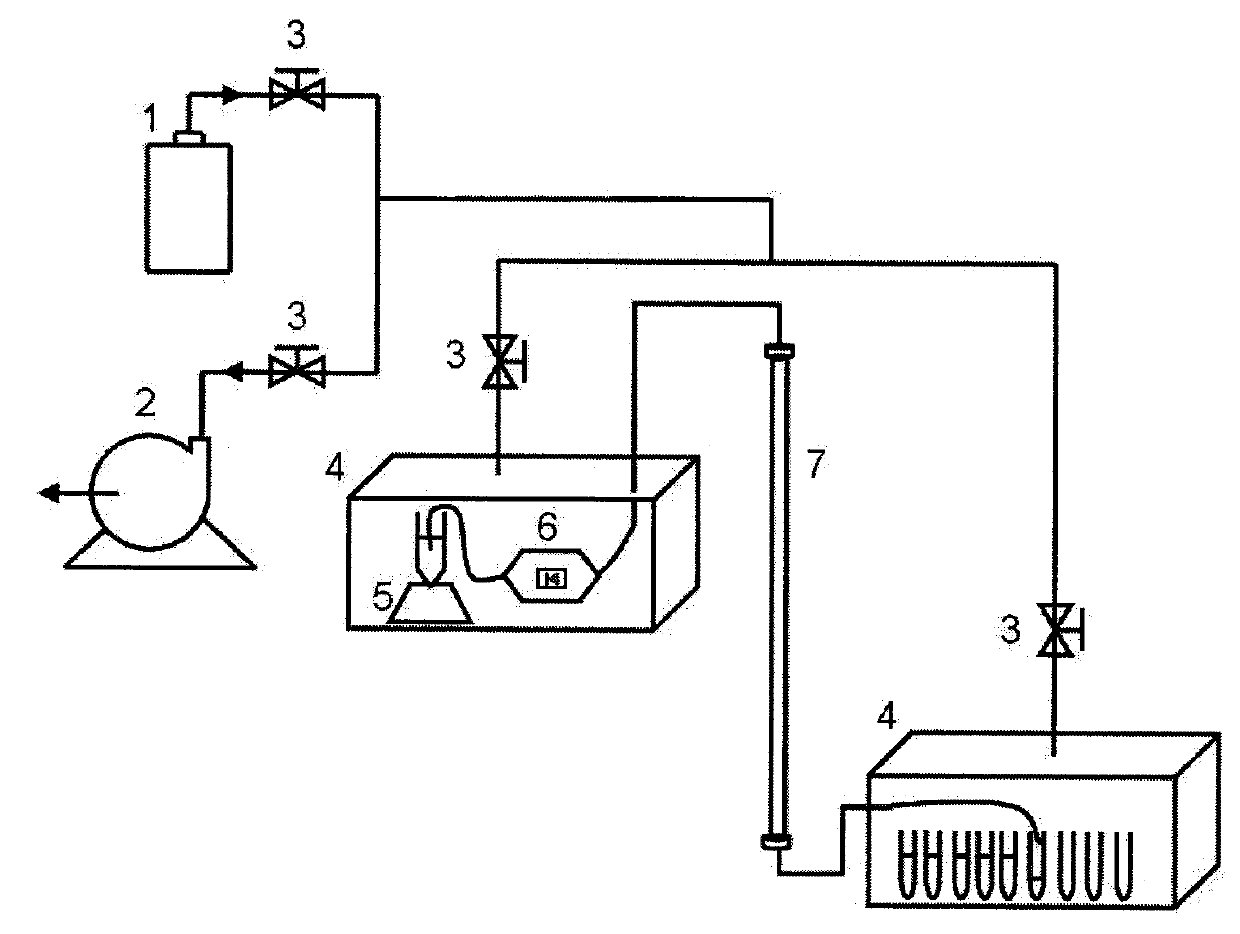

Sealing system composed of small anaerobic operation bags and chromatography column in series

A chromatographic column, small-scale technology, applied in the direction of oxidoreductase, peptide preparation, organic chemistry, etc., can solve the problems of inability to obtain effective protection immediately, protein inactivation, high cost, etc., and achieve simple and convenient operation, protection activity, The effect of reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Separation and Purification of Hydrogenase from Tetragalensis Subcordiformis in Seawater

[0035] In step 1, take the late logarithmic growth period, and the concentration is about 2×10 6 3L of cells / mL Tetraphyllum subcordiformis, concentrated by centrifugation at 1500r / min for 2min. After pouring out the seawater, take 10g of algae cells with a fresh weight, resuspend in 100mL of sterilized seawater, and place them in a closed glass bottle. Nitrogen was passed for 10 minutes, and after the oxygen in the container was excluded, induction was carried out in the dark for 4 hours.

[0036] Step 2 Put the glass bottle into the anaerobic operation bag and fill it with N repeatedly 2 1. After vacuuming three times, divide the algae solution into sealed centrifuge tubes, centrifuge at 1500r / min for 3min, remove the supernatant and resuspend in 10mL of 50mM Tris-Hcl buffer solution with pH7.9. Add 10 g of pre-cooled glass beads (diameter 1 mm) to the resuspension, vortex at...

Embodiment 2

[0043] Isolation and purification of freshwater Chlamydomonas reinhardtii cc124 hydrogenase

[0044] In step 1, the late logarithmic growth is taken, and the concentration is about 2.5×10 6 cells / mL of Chlamydomonas reinhardtii cc124 3L, concentrated by centrifugation at 4000r / min for 5min. After pouring off the supernatant, take 10 g of algae cells with a fresh weight, resuspend them in 100 mL of 50 mM pH7.2 phosphate buffer, and place them in an airtight glass bottle. Nitrogen was passed for 10 minutes, and after the oxygen in the container was excluded, it was induced in the dark for 3 hours.

[0045] Step 2 Put the glass bottle into the anaerobic operation bag and fill it with N repeatedly 2 1. After vacuuming three times, divide the algae solution into sealed centrifuge tubes, centrifuge at 4000r / min for 5min, remove the supernatant and resuspend in 10mL of 50mM Tris-Hcl buffer solution with pH8.5. Add 10 g of pre-cooled glass beads (0.8 mm in diameter) to the resuspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com