Method for preparing agrocybe cylindracea hydrolysate by using compound enzyme method

A technology of mushroom hydrolyzate and compound enzyme method, which is applied in the field of preparation of tea tree mushroom hydrolyzate by compound enzyme method, can solve the problems of low extraction efficiency and low enzyme activity, and achieve the effects of improving extraction rate, reducing operation steps and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

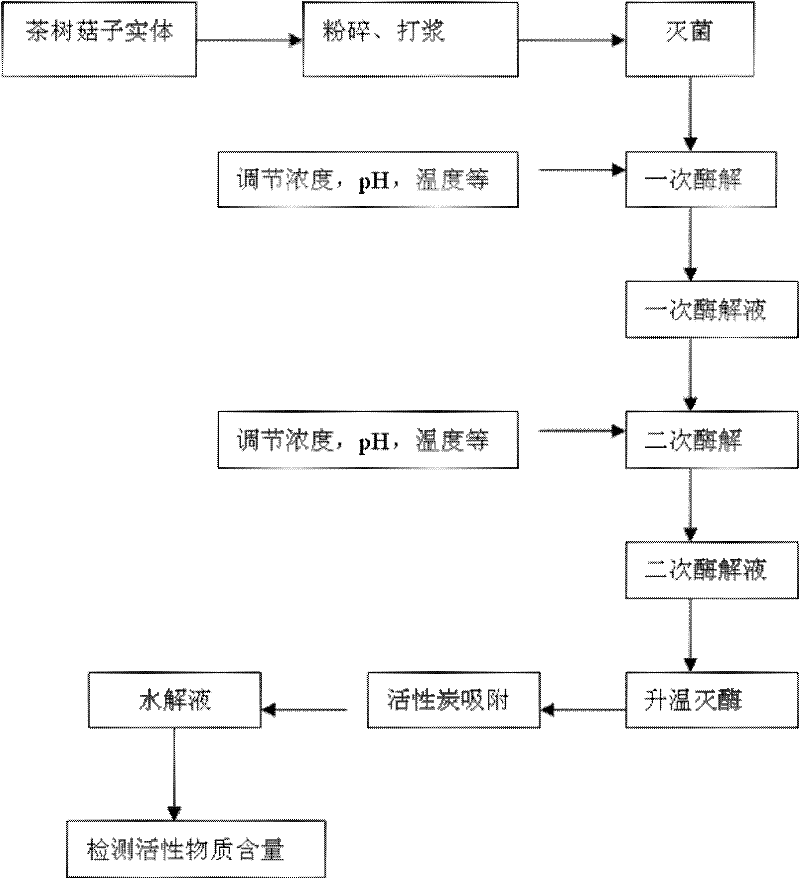

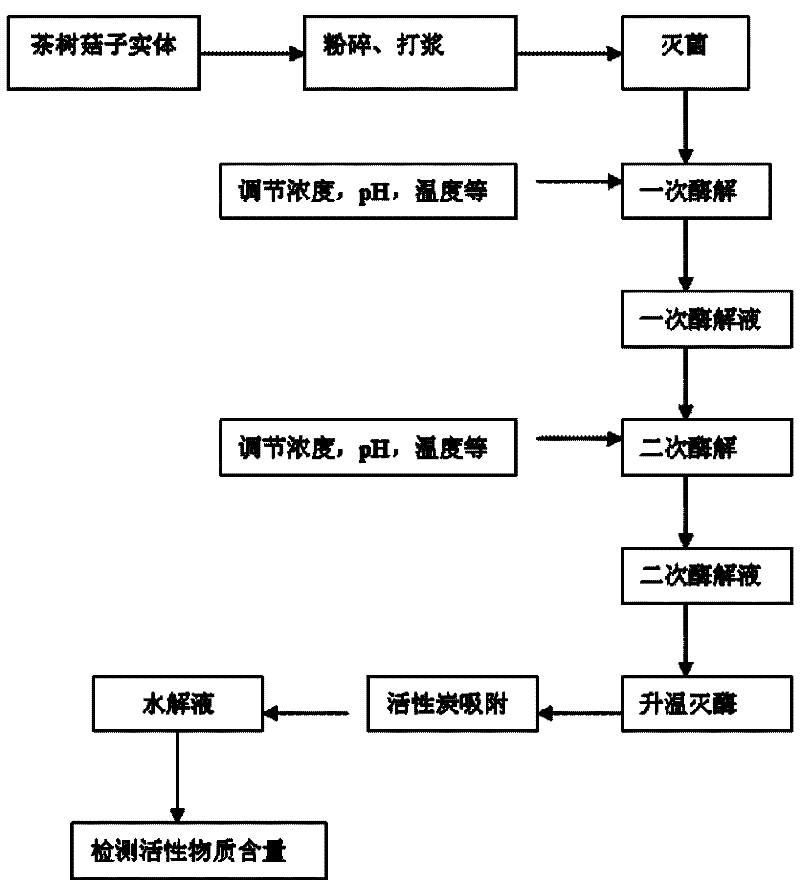

Method used

Image

Examples

Embodiment 1

[0028] A method for preparing tea tree mushroom hydrolyzate by compound enzyme method, the steps are as follows:

[0029] (1) Wash 1 kg of dried tea tree mushroom, crush it into 80 meshes, add water to make slurry according to the weight ratio of tea tree mushroom and water as 1:2, boil for 15 minutes to sterilize, and obtain slurry;

[0030] (2) The first enzymatic hydrolysis: first, add water to adjust the concentration of the slurry, so that the ratio of the weight of the dry tea tree mushroom raw material to water is 1:20 (kg:L), add 20L water to 1kg of tea tree mushroom, and then use food grade Adjust the pH value with citric acid or dilute hydrochloric acid to keep the pH value at 4.5. Then, add compound enzyme I and perform enzymatic hydrolysis for 3 hours at 45-55°C. The temperature can be adjusted with a water bath heater, and the enzymatic hydrolysis is stirred at a slow speed. Carry out under the state, obtain the enzymolysis solution for the first time;

[0031] A...

Embodiment 2

[0040] A method for preparing tea tree mushroom hydrolyzate by compound enzyme method, the steps are as follows:

[0041] (1) Wash 2 kg of dried tea tree mushroom, crush it, add water to adjust the slurry according to the weight ratio of tea tree mushroom and water as 1:5, boil for 15 minutes to sterilize, and obtain a slurry;

[0042] (2) The first enzymatic hydrolysis: First, add water to adjust the concentration of the slurry, so that the ratio of the weight of the dry tea tree mushroom raw material to water is 1:20 (kg:L), add 40L water to 1kg of tea tree mushroom, and then use food grade Adjust the pH value with citric acid or dilute hydrochloric acid to keep the pH value at 5.0. Then, add compound enzyme I and perform enzymolysis at 50°C for 3 hours. The temperature can be adjusted with a water bath heater, and the enzymolysis is under slow stirring. Carry out to obtain the first enzymolysis solution;

[0043]Composite enzyme I is made up of cellulase 3g, xylanase 3g, β...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com