Fluoro-polyester resin and preparation method and application thereof

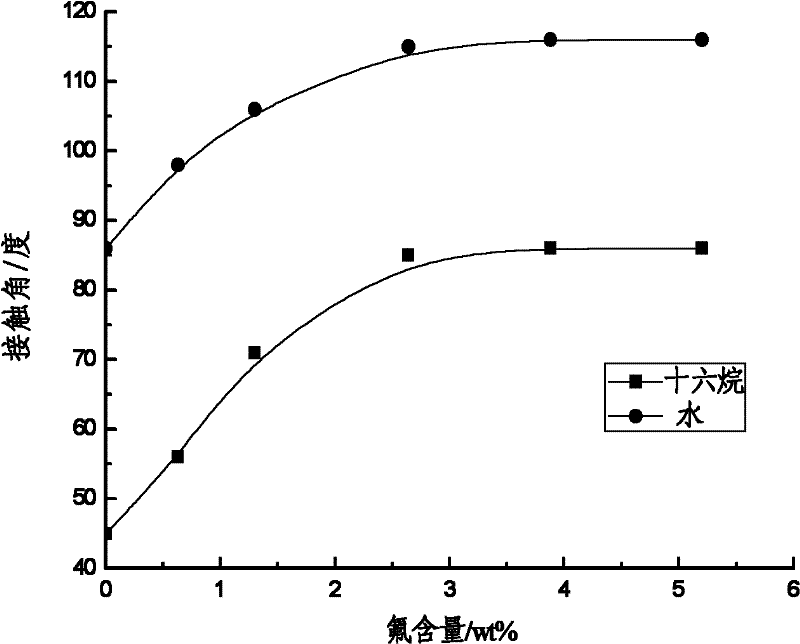

A technology of fluorine-containing polyester and resin, which is applied in the field of polymers to achieve the effects of reducing requirements, improving hydrophobicity, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Formula for synthesizing tetrafluoropropyl glycidyl ether

[0067] Element

Mass / g(mol / mol)

[0068] Epichlorohydrin

55.5(6.0×10 -1 )

Tetrafluoropropanol

13.20(1.0×10 -1 )

0.105(5.0×10 -4 )

4.2(1.05×10 -1 )

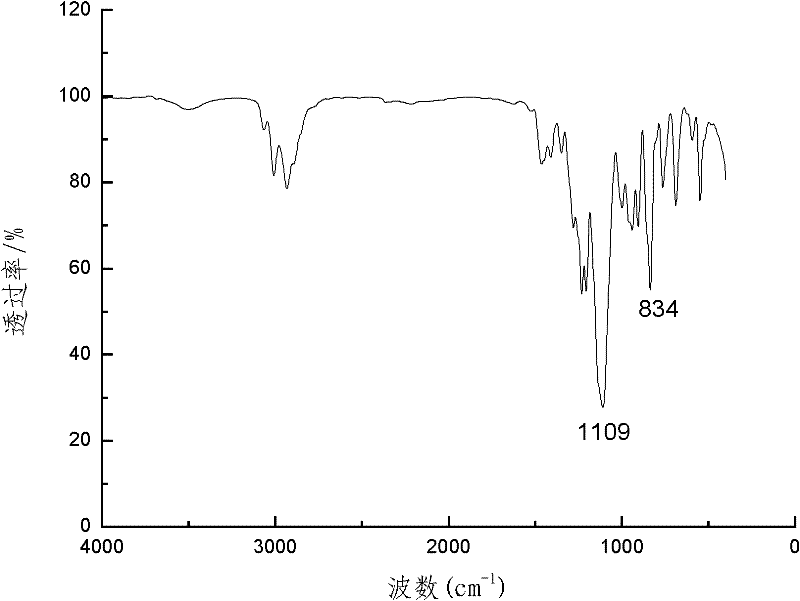

[0069] Synthesize tetrafluoropropyl glycidyl ether according to the above formula, add epichlorohydrin (55.5g / 6.0×10 -1 mol) and tetrafluoropropanol (HCF 2 CF 2 CH 2 OH) (13.20g / 1.0×10 -1 mol), in 0.105g (5.0×10 -4 mol) tetraethylammonium bromide as a catalyst, and add 10mL of toluene as a solvent, heat and stir, after the temperature rises to 70°C, add a total of 4.2g of sodium hydroxide in five equal amounts (1.05×10 -1 mol), reacted for 5h, and then rectified the resulting product to collect fractions at 135°C to 145°C. The collected fractions were analyzed by infrared spectrogram, and the results were as follows: figure 1 , indicating ...

Embodiment 2

[0077] In addition to using 1.0g (5.347×10 -3 mol) synthetic tetrafluoropropyl glycidyl ether and 8.756g (9.653 × 10 -2 mol) of epichlorohydrin instead of 0.5g (2.674 × 10 -3 mol) tetrafluoropropyl glycidyl ether and 9.0g (9.733×10 -2 mol) except the epichlorohydrin, all the other conditions are identical with embodiment 1, make fluorine-containing polyester resin and hydrophobic fluorine-containing polyester powder coating finished product.

Embodiment 3

[0079] In addition to using 2.0g (1.070×10 -2 mol) synthetic tetrafluoropropyl glycidyl ether and 8.260g (8.930 × 10 -2 mol) epichlorohydrin replaces 0.5g (2.674 × 10 -3 mol) tetrafluoropropyl glycidyl ether and 9.0g (9.733×10 -2 mol) except the epichlorohydrin, all the other conditions are identical with embodiment 1, make fluorine-containing polyester resin and hydrophobic fluorine-containing polyester powder coating finished product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com