Drying and water-recovering process of heat conduction coal by venturi injecting circulation of tail gas with low oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

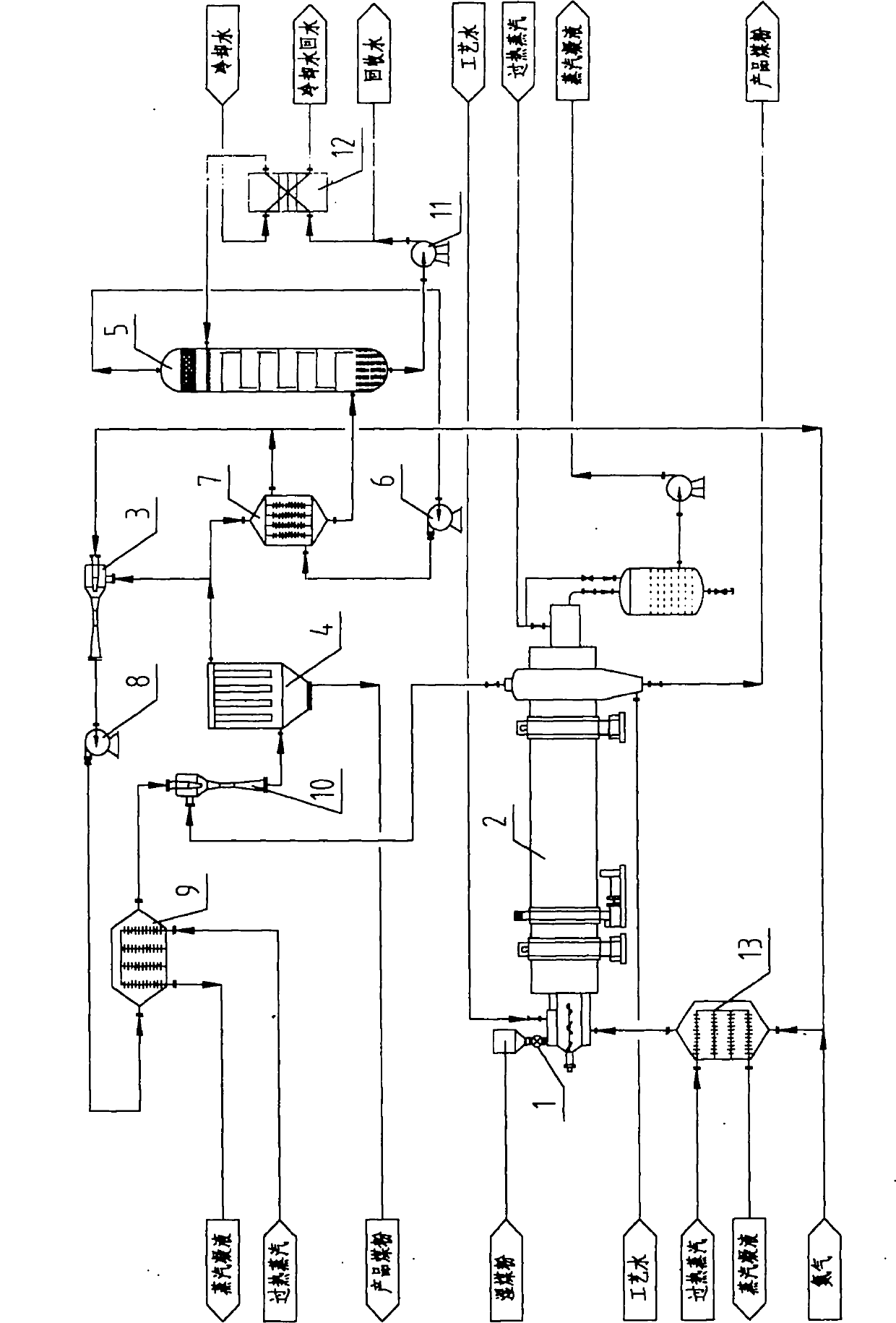

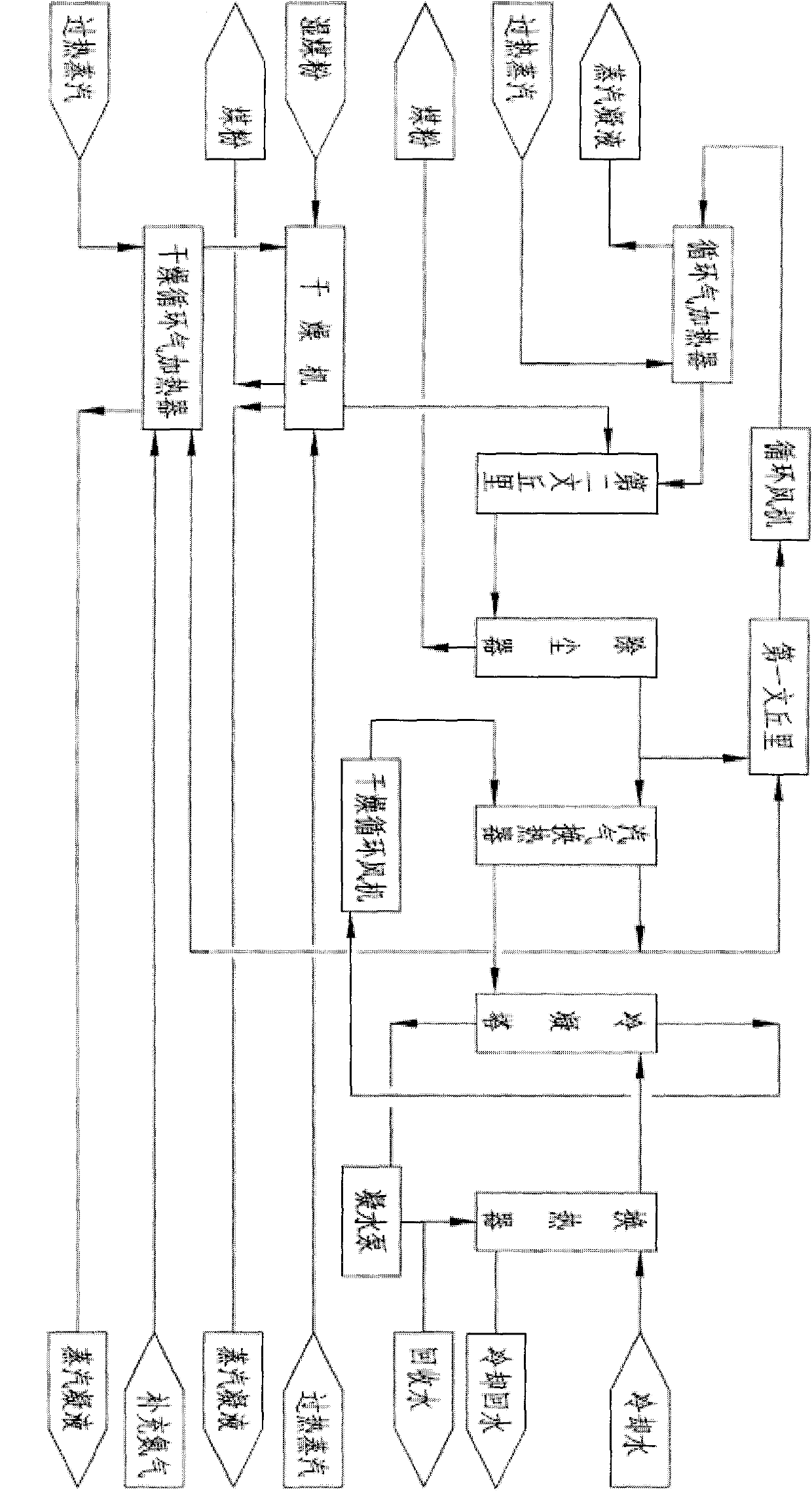

[0041] Below, in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0042] The heat conduction dryer (2) used in this implementation is a steam tube rotary dryer, the dust collector (4) is a cyclone separator, and the condensation tower (5) is a plate type condensation tower.

[0043] The heat source used for drying wet coal is superheated steam.

[0044] like Figure 1-2 As shown, a Venturi ejection low-oxygen tail gas circulation heat conduction briquette drying and water recovery process, its process flow is:

[0045] Wet coal enters the heat conduction dryer 2 through the rotary feed valve 1, and while moving from the inlet to the outlet of the dryer 2, it is fully mixed and indirectly heated by the heat conduction dryer 2 with superheated steam, and when it reaches the outlet of the dryer When the wet coal is dried into a qualified product, it is discharged from the feed port of the dryer; during the drying process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com