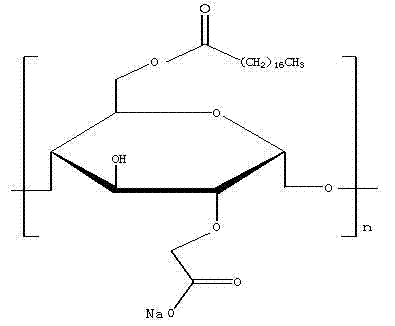

Carboxymethyl starch stearate and its preparation method

A technology of carboxymethyl starch and stearate, applied in the field of compound modified starch, achieves the effects of simple operation, good freeze-thaw stability and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

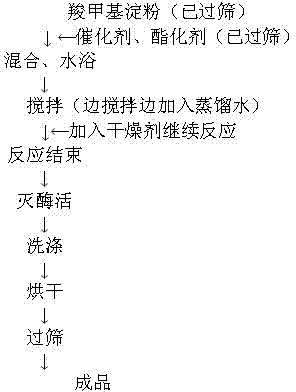

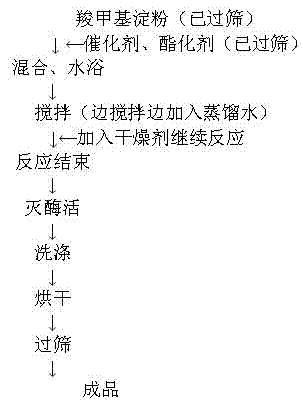

Method used

Image

Examples

Embodiment 1

[0018] 3g stearic acid is pulverized, crosses 120 mesh sieves, then joins 100g (dry basis) in the carboxymethyl starch that crosses 120 mesh sieves, carboxymethyl starch substitution degree is 0.2081, then adds lipase (enzyme activity 5000u / g , the amount of enzyme added is 0.5g), heated and stirred in a water bath at 45°C, and the stirring rate was 120r / min; while stirring, add distilled water to control the water content of the system to 7%; after 1 hour of reaction, add desiccant and color-changing silica gel, and continue to stir for 3 hours to react End; after the reaction is over, inactivate the enzyme in a boiling water bath for 20 minutes, then wash with industrial alcohol until no precipitation reaction occurs with the silver nitrate solution; put the alcohol in an oven at 45°C to dry the alcohol, and finally sieve to remove the desiccant to obtain the product Carboxylic acid Methyl Starch Stearate.

[0019] Table 1 is the comparison of carboxymethyl starch stearate p...

Embodiment 2

[0024] Add distilled water to control the moisture content of the system to be 8.3%, and all the other operations and formulas are the same as in Example 1.

Embodiment 3

[0026] Lipase consumption is 1.5000g, and all the other operations and prescriptions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com