Method for preparing monodisperse flaky magnesium hydroxide flame retardant

A technology of magnesium hydroxide and flame retardant, applied in magnesium hydroxide and other directions, can solve the problems of irregular shape of magnesium hydroxide, high equipment requirements, difficult filtration, etc., and achieves low equipment material requirements, low production cost, and low technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

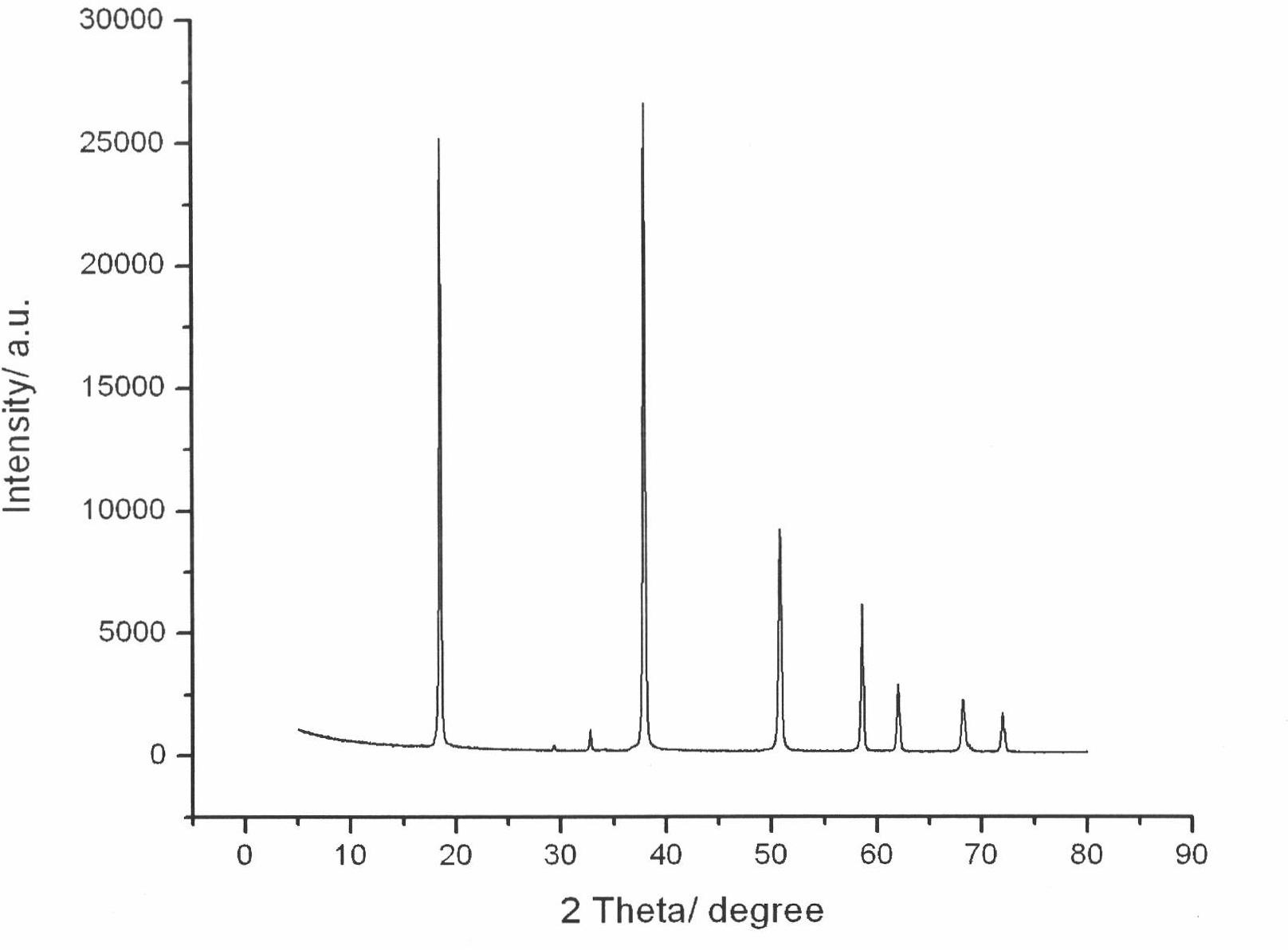

[0025] 1. Dissolve bischofite with deionized water, filter to remove insoluble impurities, calibrate the magnesium ion concentration to 4.00mol / l by EDTA method, and obtain a magnesium chloride solution for use;

[0026] 2. Take 300ml of 8.00mol / l sodium hydroxide solution and add it to the IPC-3A intelligent reactor at a speed of 2500rpm. After the sodium hydroxide solution is heated to 60°C, add magnesium ions at a flow rate of 10ml / min. 300ml of the above-mentioned magnesium chloride solution of 4.00mol / l;

[0027] 3. After adding the magnesium chloride solution, continue to react at a constant temperature of 60°C and a rotating speed of 2500rpm for 60 minutes, dilute the reacted slurry with deionized water until the concentration of magnesium hydroxide is 10% by mass;

[0028] 4. Take 400ml of the diluted slurry and put it into a 2L autoclave for hydrothermal reaction at 200°C and 700rpm for 1h;

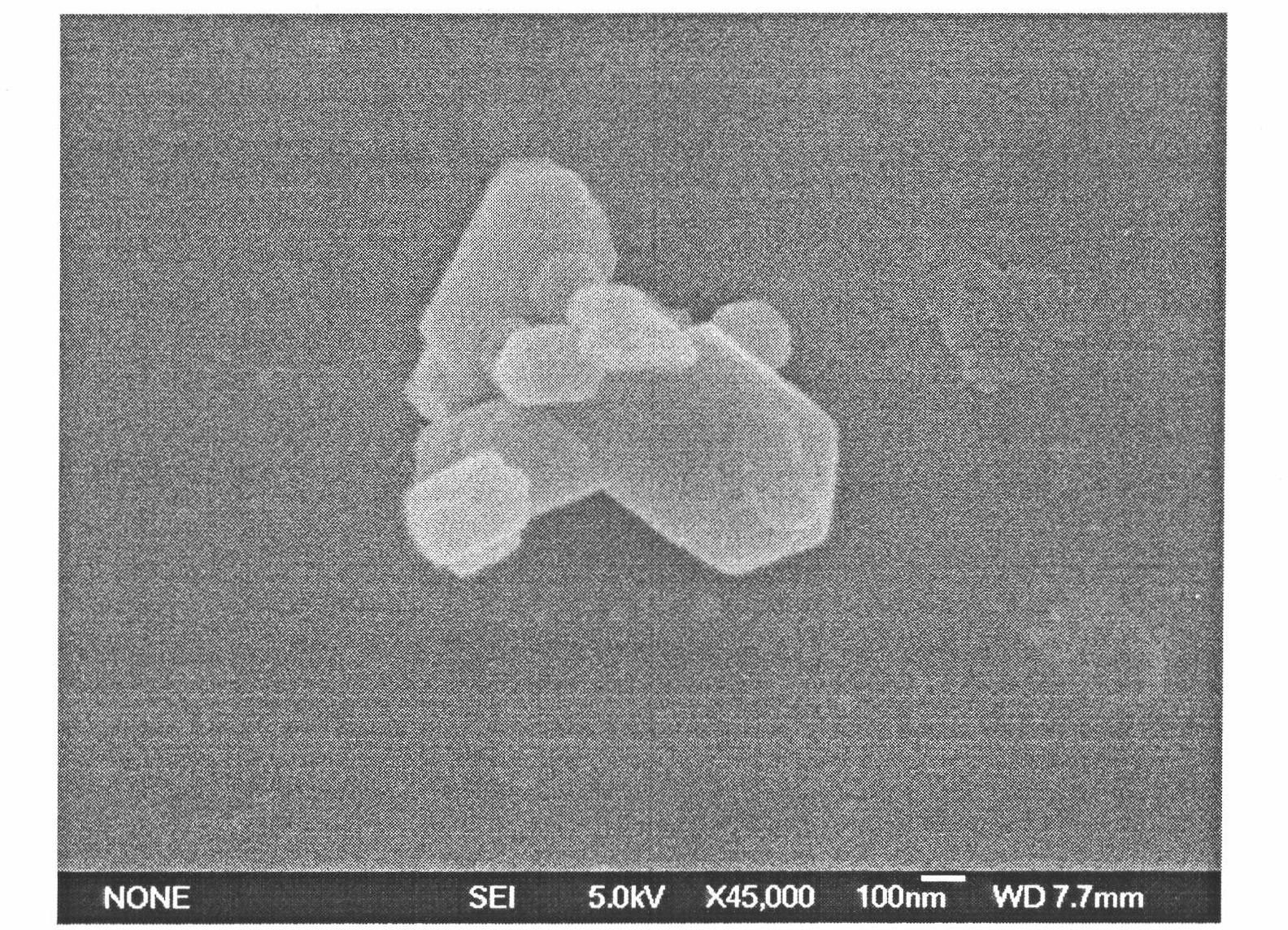

[0029] 5. Dry the filtered and washed product at 100°C for 6 hours to obtai...

Embodiment 2

[0034] 1. Dissolve bischofite with deionized water, filter to remove insoluble impurities, calibrate the magnesium ion concentration to 3.45mol / l by EDTA method, and obtain a magnesium chloride solution for use;

[0035] 2. Take 300ml of 6.90mol / l sodium hydroxide solution and add it to the IPC-3A intelligent reactor at a speed of 2500rpm. After the sodium hydroxide solution is heated to 60°C, add magnesium ions at a flow rate of 10ml / min. 300ml of the above-mentioned magnesium chloride solution of 3.45mol / l;

[0036] 3. After adding the magnesium chloride solution, continue to react at a constant temperature of 60°C and a rotating speed of 2500rpm for 60 minutes, dilute the reacted slurry with deionized water until the concentration of magnesium hydroxide is 10% by mass;

[0037] 4. Take 400ml of the diluted slurry and put it into a 2L autoclave for hydrothermal reaction at 120°C and 400rpm for 4h;

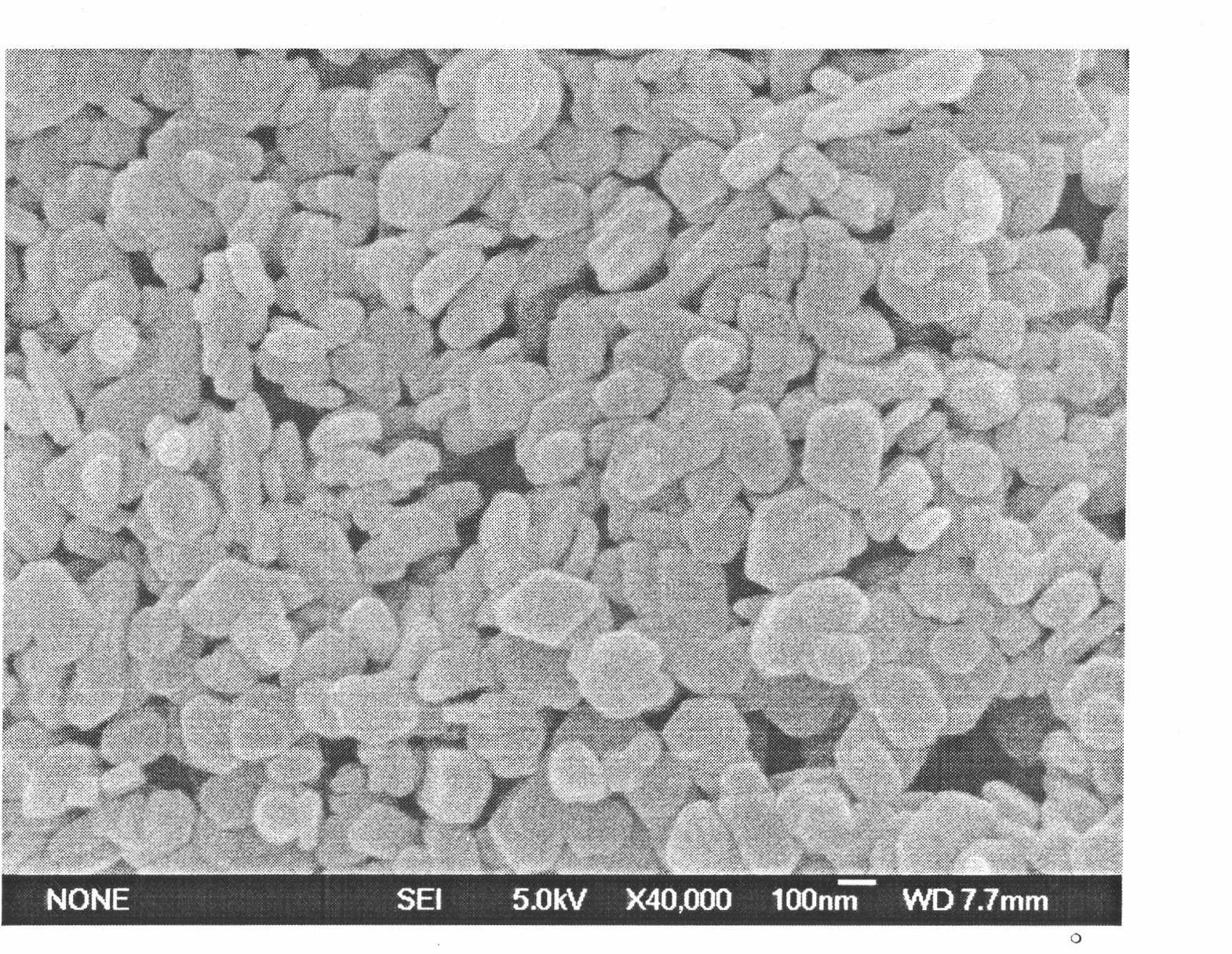

[0038] 5. Dry the filtered and washed product at 120°C for 6 hours to obtai...

Embodiment 3

[0043] 1. Dissolve magnesium sulfate with deionized water, filter to remove insoluble impurities, and calibrate the concentration of magnesium ions to 0.5mol / l by EDTA method to obtain magnesium sulfate solution for use;

[0044] 2. Take 300ml of 0.5mol / l sodium hydroxide solution and add it to the IPC-3A intelligent reactor at a speed of 2500rpm. After the sodium hydroxide solution is heated to 60°C, add magnesium ions at a flow rate of 10ml / min. 150ml of 0.5mol / l solution;

[0045] 3. After adding the magnesium sulfate solution, continue to react at a constant temperature of 60°C and a rotating speed of 2500rpm for 60 minutes, dilute the reacted slurry with deionized water until the concentration of magnesium hydroxide is 10% by mass;

[0046] 4. Take 400ml of the diluted slurry and put it into a 2L autoclave for hydrothermal reaction at 100°C and 700rpm for 4h;

[0047] 5. Dry the washed product at 120°C for 6 hours to obtain the desired product.

[0048] The test results...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com