Method for safely preparing fireworks chemical by boiling granulating process

A pyrotechnic agent and process safety technology, applied in the direction of non-explosive/non-thermal agent components, explosives, offensive equipment, etc., can solve the problems of low efficiency, prone to explosion accidents, etc., and achieve no dust, simple addition and granulation process , Uniform effect of drug particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

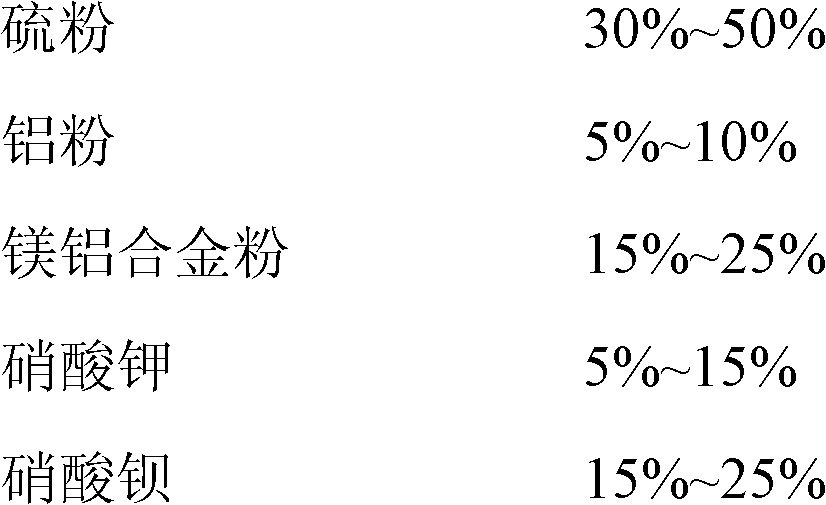

[0013] The formula of the pyrotechnic agent used is:

[0014]

[0015] (1) Weigh fine powdered sulfur powder, aluminum powder, magnesium-aluminum alloy powder, potassium nitrate, barium nitrate, potassium dichromate and cooked glutinous rice flour to 3.32kg, 0.676kg, 1.576kg, 0.732kg, 1.688kg respectively , 0.12kg and 0.2kg, and cooked glutinous rice flour is made into an aqueous solution with a mass fraction of 5%, and it is cooled to room temperature after heating and boiling;

[0016] (2) the original composition of the medicament weighed in 1) and potassium dichromate are mixed homogeneously by the airflow of 1m / s with velocity in the boiling granulator;

[0017] (3) Atomize the solution prepared in 1) at a rate of 100ml / min under a pressure of 0.2MPa and spray it into the granulator in 2), and at the same time, use an airflow rate of 1m / s and a temperature of 40°C to spray the atomized solution Prepare granular medicaments with fine powder medicaments, and obtain the ...

Embodiment 2

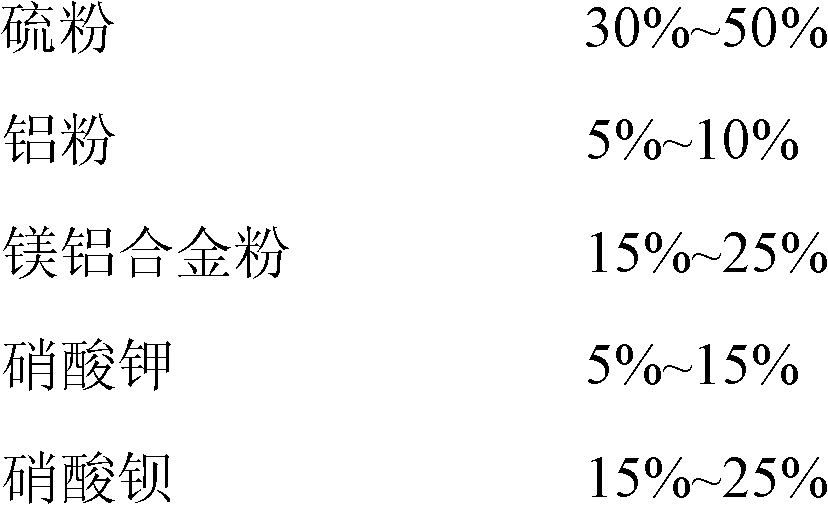

[0020] The formula of the pyrotechnic agent used is:

[0021]

[0022] (1) Weigh fine powdered sulfur powder, aluminum powder, magnesium-aluminum alloy powder, potassium nitrate, barium nitrate, potassium dichromate and cooked glutinous rice flour to 3.32kg, 0.676kg, 1.576kg, 0.732kg, 1.688kg respectively , 0.16kg and 0.24kg, and cooked glutinous rice flour is made into an aqueous solution with a mass fraction of 6%, which is cooled to room temperature after heating and boiling;

[0023] (2) the original composition of the medicament weighed in 1) and Potassium Dichromate are uniformly mixed with a velocity of 1.5m / s in the fluidized granulator;

[0024] (3) Atomize the solution prepared in 1) at a rate of 150ml / min under a pressure of 0.4MPa and spray it into the granulator in 2), and at the same time atomize the solution with a rate of 1.5m / s and a temperature of 50°C The solution and the fine powder medicine are prepared into granular medicine, and the target product is...

Embodiment 3

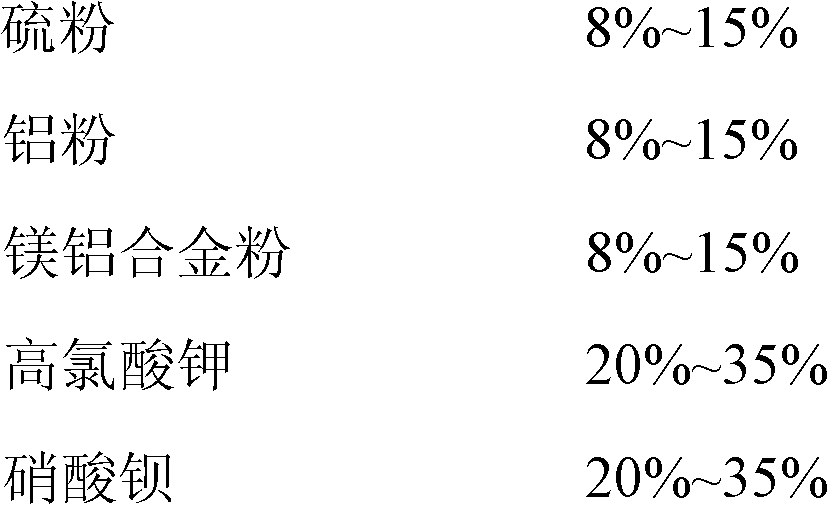

[0027] The formula of the pyrotechnic agent used is:

[0028]

[0029] (1) Weigh 1kg, 1kg, 1kg, 2.5kg, 2.5kg, 0.24kg of fine powdered sulfur powder, aluminum powder, magnesium aluminum alloy powder, potassium perchlorate, barium nitrate, potassium dichromate and cooked glutinous rice flour respectively and 0.32kg, and cooked glutinous rice flour is made into a mass fraction of 7% aqueous solution, heated and boiled and down to room temperature;

[0030] (2) the original composition of the medicament weighed in 1) and potassium dichromate are mixed homogeneously by the air flow of 2m / s in the boiling granulator;

[0031] (3) Atomize the solution prepared in 1) at a rate of 200ml / min under a pressure of 0.6MPa and spray it into the granulator in 2), and at the same time, use an airflow rate of 2m / s and a temperature of 60°C to spray the atomized solution Prepare granular medicaments with fine powder medicaments, and obtain the target product after drying.

[0032] There is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com