Schottky diode controlled by junction barrier having superposed P<+>-P structure

A technology of Schottky diode and junction barrier, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems that Schottky contacts are easily affected by surface charges, large reverse leakage current, and high design requirements, and achieve reduction The effect of small number of carrier charges, improved reverse withstand voltage, and strong implementability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

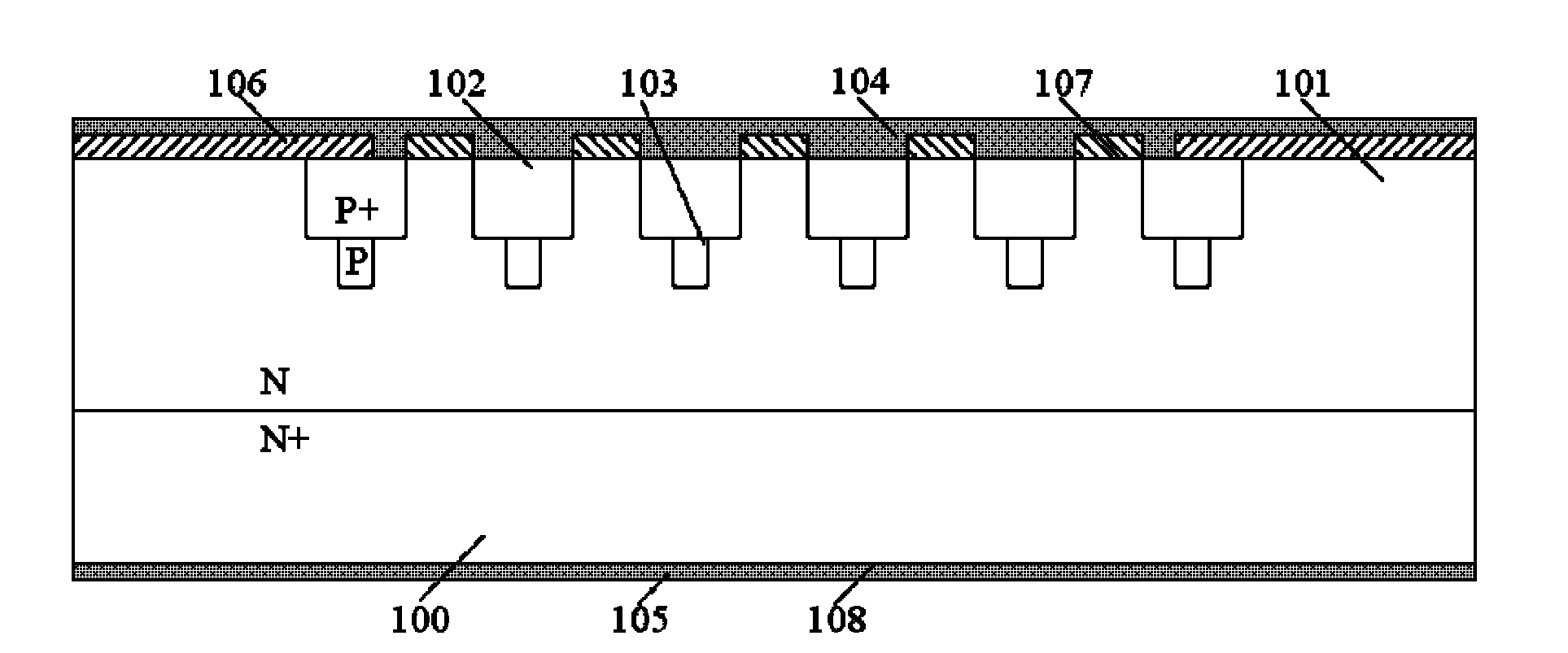

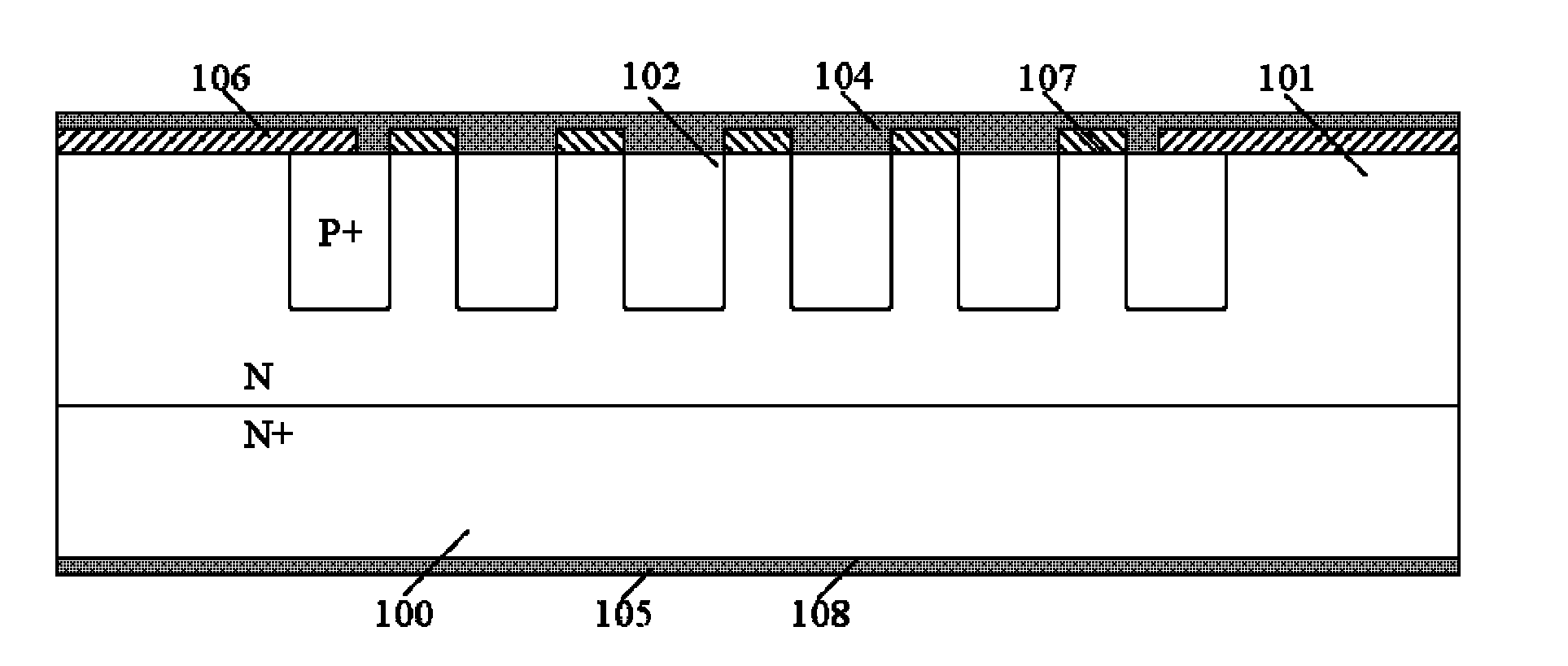

[0017] refer to figure 1 , the stacked P+-P junction barrier of the present invention controls the Schottky diode. Including N+ substrate region 100, N-type drift region 101, stacked P+-P structure P+ part 102, stacked P+-P structure P part 103, anode electrode 104, cathode electrode 105, silicon dioxide layer 106, Schottky Contact 107, ohmic contact 108. According to the requirements of the specific conduction characteristics and breakdown characteristics of the device, determine figure 1 The doping concentration and two-dimensional size of the drift region 101, and the two-dimensional size of the silicon dioxide layer 106.

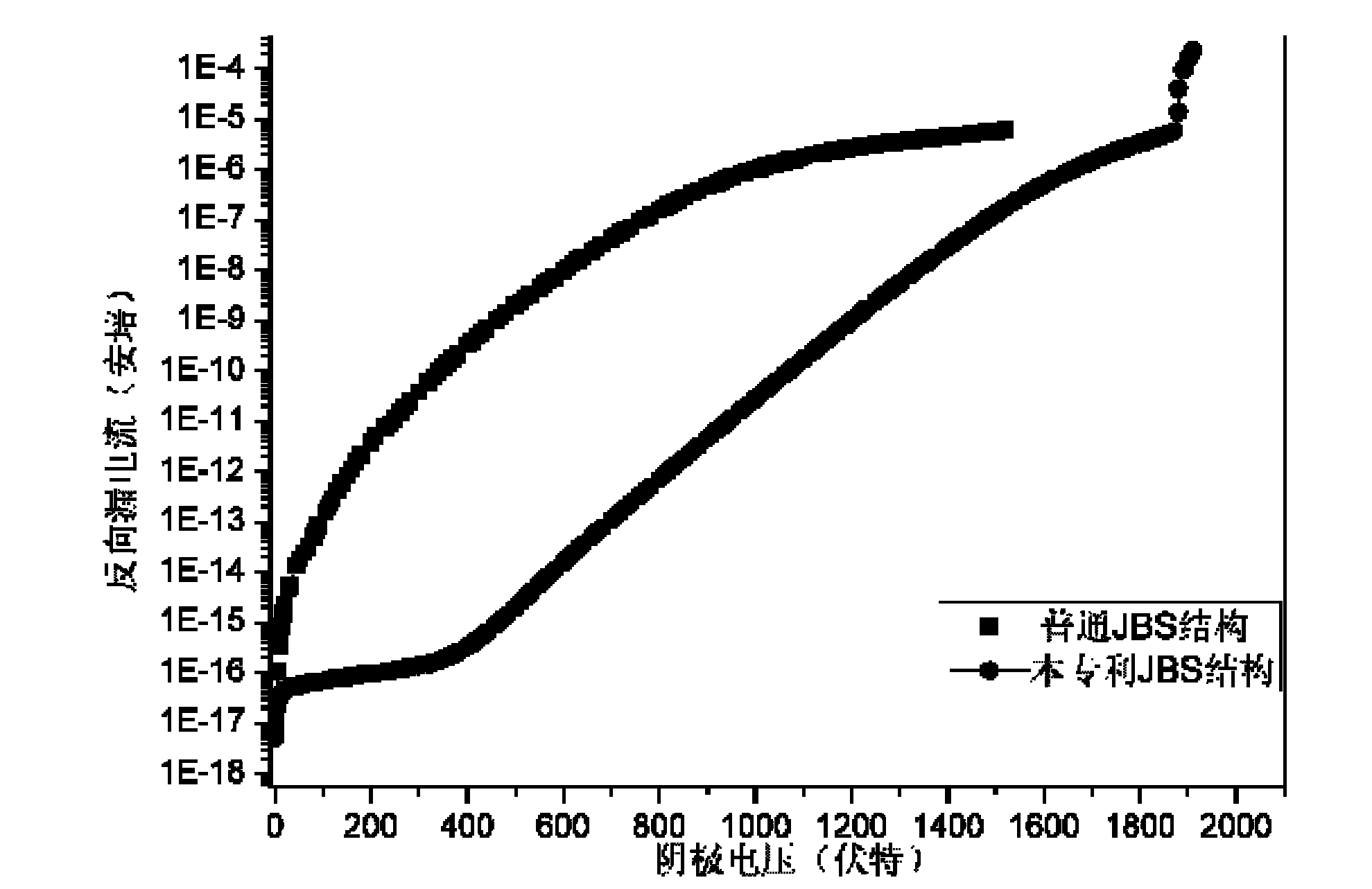

[0018] refer to image 3 , it can be seen from the comparison of the breakdown voltage characteristics of the stacked P+-P junction barrier controlled Schottky diode device of the present invention and the common junction barrier Schottk...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com