Silk solution, organic thin film transistor prepared by using silk solution, capacitor and manufacturing method thereof

An organic thin film and transistor technology, which is applied in the field of silk solution, organic thin film transistors and capacitors prepared by using the same, and a manufacturing method thereof, can solve the problems of increasing manufacturing cost and process complexity, and is beneficial to large-area production and improving transistors. Features, cheap effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

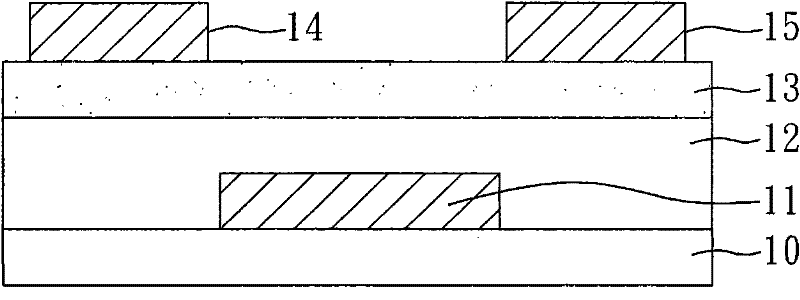

[0044] Example 1 - Top Contact Organic Thin Film Transistor Device

[0045] Preparation of silk aqueous solution

[0046] Firstly, prepare an aqueous solution containing 10 wt% sodium carbonate, heat it to boiling, add dry cocoons (natural silk) and boil for 30 minutes to 1 hour to remove sericin (sericin) on the outer layer of silk. Then, put it into deionized water for washing to wash away the lye attached to the outer layer of silk. After drying, the refined silk protein, namely fibroin, can be obtained.

[0047] Then, put the refined silk protein into 20ml of 85wt% phosphoric acid (H 3 PO 4 ) solution, stirred until dissolved. Then, the phosphoric acid solution dissolved in silk protein was put into a dialysis membrane (Spectra / Por 3 dialysis membrane, molecular weight cutoff = 14000) and dialyzed against water for 3 days to remove excess phosphate groups. By changing the volume of water used for dialysis and the number of dialysis times, in addition to removing phosp...

Embodiment 2

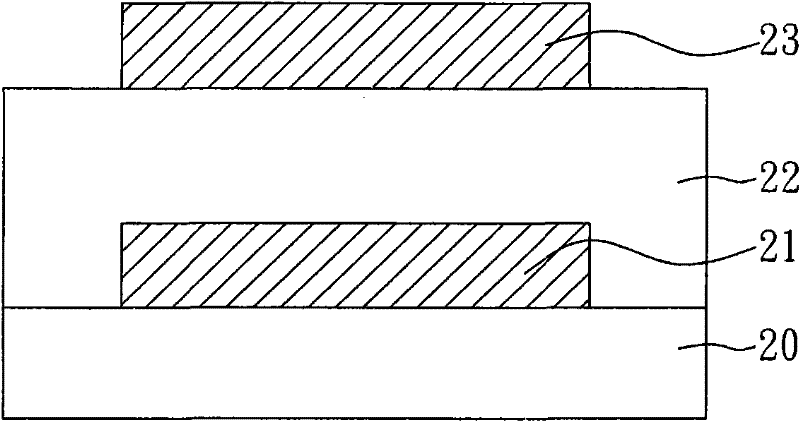

[0065] Example 2 - Bottom Contact Organic Thin Film Transistor Device

[0066] Such as Figure 6A As shown, a substrate 30 is provided, and a gate 31 and a gate dielectric layer 32 are sequentially formed on the substrate 30 . In this embodiment, the materials and preparation methods of the substrate 30 , the gate 31 , and the gate dielectric layer 32 are the same as those in the first embodiment. In addition, in this embodiment, the thickness of the gate 31 is about 100 nm, and the thickness of the gate dielectric layer 32 is about 500 nm.

[0067] Next, if Figure 6B As shown, a patterned metal layer is evaporated on the gate dielectric layer 32 to serve as the source 34 and the drain 35 by using the same process conditions as in the embodiment 1 for forming the gate. In this embodiment, the material of the source electrode 34 and the drain electrode 35 is gold, and its thickness is about 100 nm.

[0068] Finally, if Figure 6C As shown, an organic semiconductor layer 3...

Embodiment 3-MI

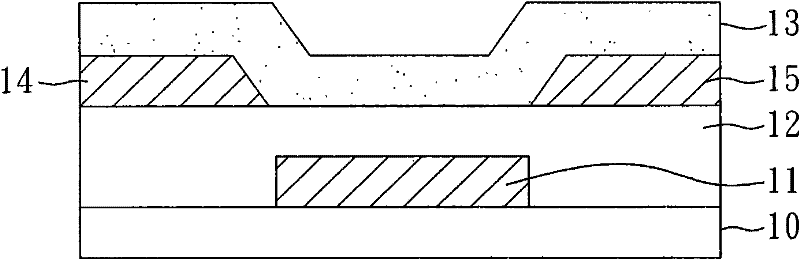

[0070] Embodiment 3-MIM capacitor structure

[0071] Such as Figure 7A As shown, a substrate 70 is provided, and a first electrode 71 is formed on the substrate 70 . In this embodiment, the manufacturing method of the first electrode 71 is the same as the gate manufacturing method described in the first embodiment. In this embodiment, the substrate 70 is a plastic substrate, and the material of the first electrode 71 is gold, and the thickness of the first electrode 71 is about 80 nm.

[0072] Then, the substrate 70 formed with the first electrodes 71 was immersed in the silk aqueous solution prepared in Example 1 for 15 minutes, so that the silk aqueous solution was coated on the substrate 70 formed with the first electrodes 71 . Then, drying the silk aqueous solution coated on the substrate 70 at 60° C. can form a silk film as an insulating layer 72, such as Figure 7B shown.

[0073] Finally, in a vacuum of 5×10 -6 The vacuum chamber (not shown) of torr is evaporated, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com