Compound semiconductor device and manufacturing method thereof

A manufacturing method and semiconductor technology, applied in semiconductor/solid-state device manufacturing, semiconductor devices, amplifiers, etc., can solve problems such as device threshold changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0021] In this embodiment, an MIS-type AlGaN / GaN HEMT is disclosed as a compound semiconductor device.

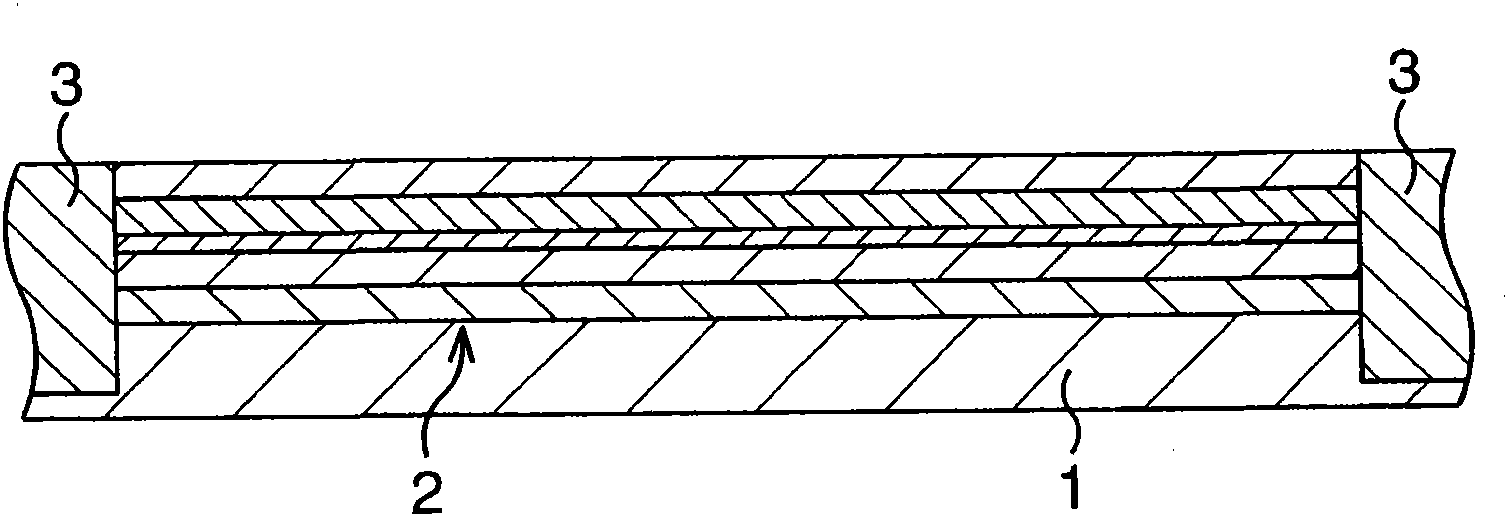

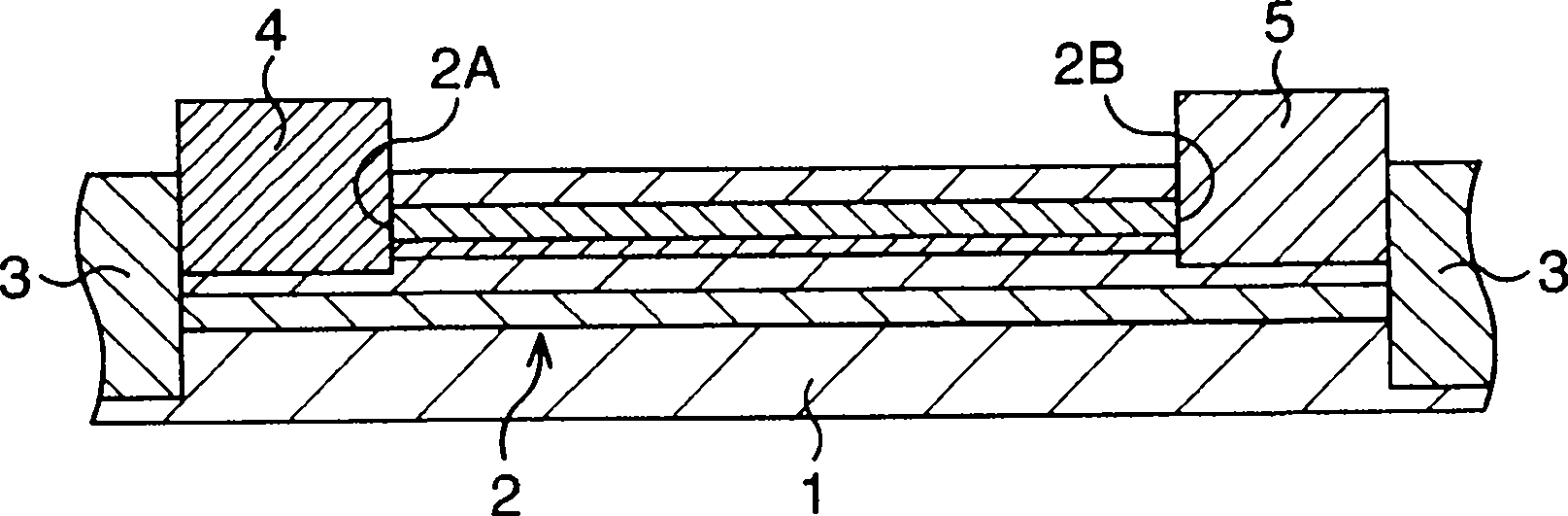

[0022] Figure 1A to Figure 3C is a schematic cross-sectional view showing a method of manufacturing the MIS-type AlGaN / GaN HEMT according to the first embodiment in process order. For the sake of illustration, in Figure 2A to Figure 3A In , only the vicinity of the gate is shown in an enlarged manner.

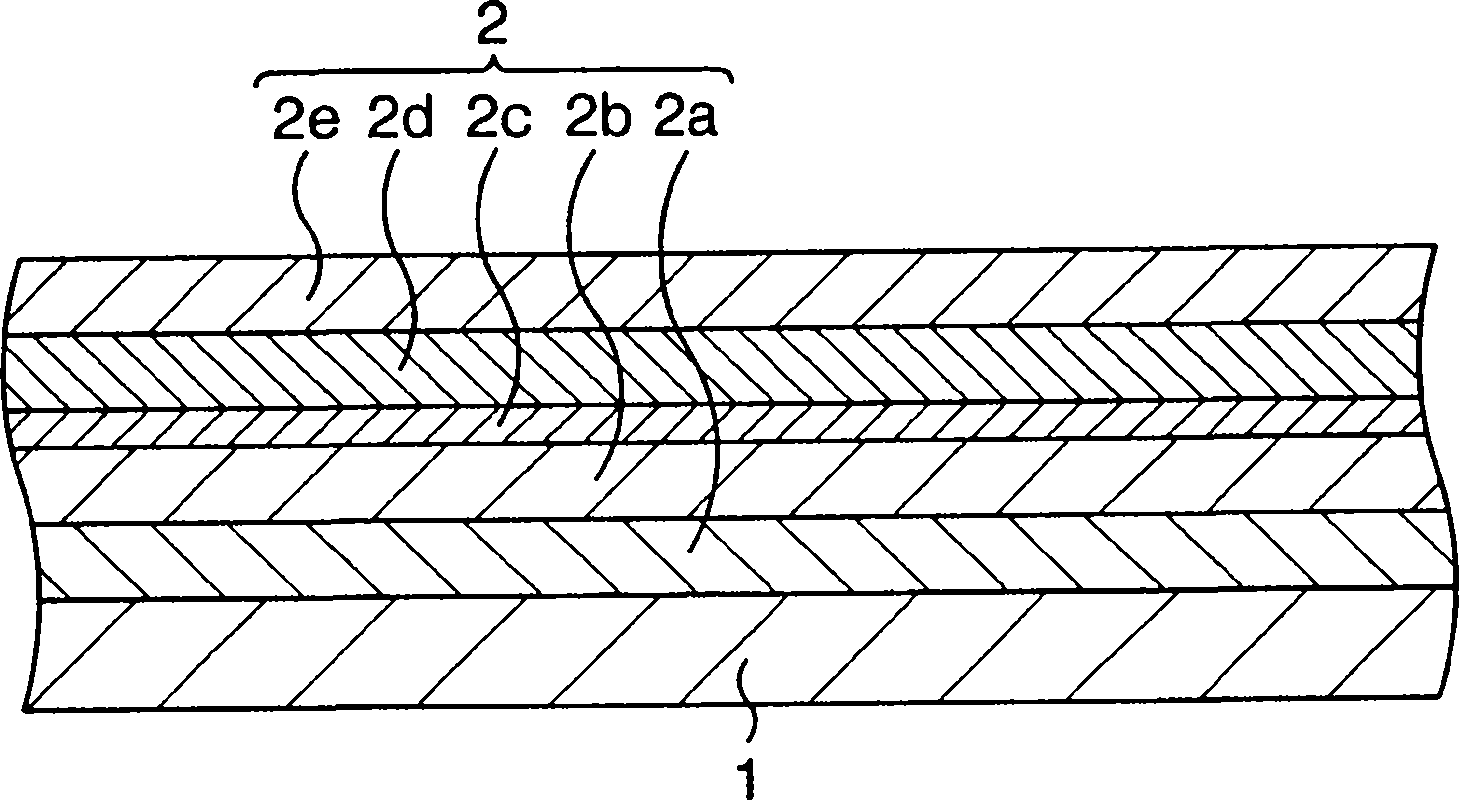

[0023] First, if Figure 1A As shown, for example, a compound semiconductor layer 2 is formed on a semi-insulating silicon carbide substrate 1 as a growth substrate. The compound semiconductor layer 2 includes a buffer layer 2a, an electron transit layer 2b, an intermediate layer 2c, an electron supply layer 2d, and a capping layer 2e. In the AlGaN / GaN HEMT, a two-dimensional electron gas (2DEG) is generated in the vicinity of the interface of the electron transit layer 2b and the electron supply layer 2d (more precisely, the intermediate layer 2c).

[0024] More spec...

no. 2 example

[0072] In this embodiment, a Schottky-type AlGaN / GaN HEMT is disclosed as a compound semiconductor device.

[0073] Image 6 It is a schematic cross-sectional view showing main processes of the method of manufacturing the Schottky-type AlGaN / GaN HEMT according to the second embodiment.

[0074] First, as in the first embodiment, execute Figure 1A to Figure 3A process to apply a fluorine termination treatment on the surface of the compound semiconductor layer 2 .

[0075] Subsequently, if Image 6 As shown, a gate 7 is formed.

[0076] More specifically, first, a lower resist (for example, product name PMGI: manufactured by U.S. MicroChem Corporation) and an upper resist (for example, product name PFI32-A8) are applied and formed on the compound semiconductor layer 2 by, for example, a spin coating method. : manufactured by Sumitomo Chemical Co., Ltd.). Openings, eg, about 0.8 μm in diameter, are formed in the upper resist by ultraviolet exposure. Next, using the upper r...

no. 3 example

[0080] In this embodiment, a power supply device including an AlGaN / GaN HEMT selected from the first embodiment and the second embodiment is disclosed.

[0081] Figure 7 is a connection diagram showing a schematic structure of a power supply device according to the third embodiment.

[0082] The power supply device according to this embodiment includes: a high-voltage primary circuit 21 , a low-voltage secondary circuit 22 ; and a transistor 23 disposed between the primary circuit 21 and the secondary circuit 22 .

[0083] The primary circuit 21 includes an AC power source 24, a so-called bridge rectifier circuit 25, and a plurality of (here, four) switching elements 26a, 26b, 26c, and 26d. Further, the bridge rectifier circuit 25 has a switching element 26e.

[0084] The secondary circuit 22 includes a plurality of (here, three) switching elements 27a, 27b, and 27c.

[0085] In this embodiment, each of the switching elements 26a, 26b, 26c, 26d, 26e of the primary circuit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com