White-light organic electroluminescent device and preparation method thereof

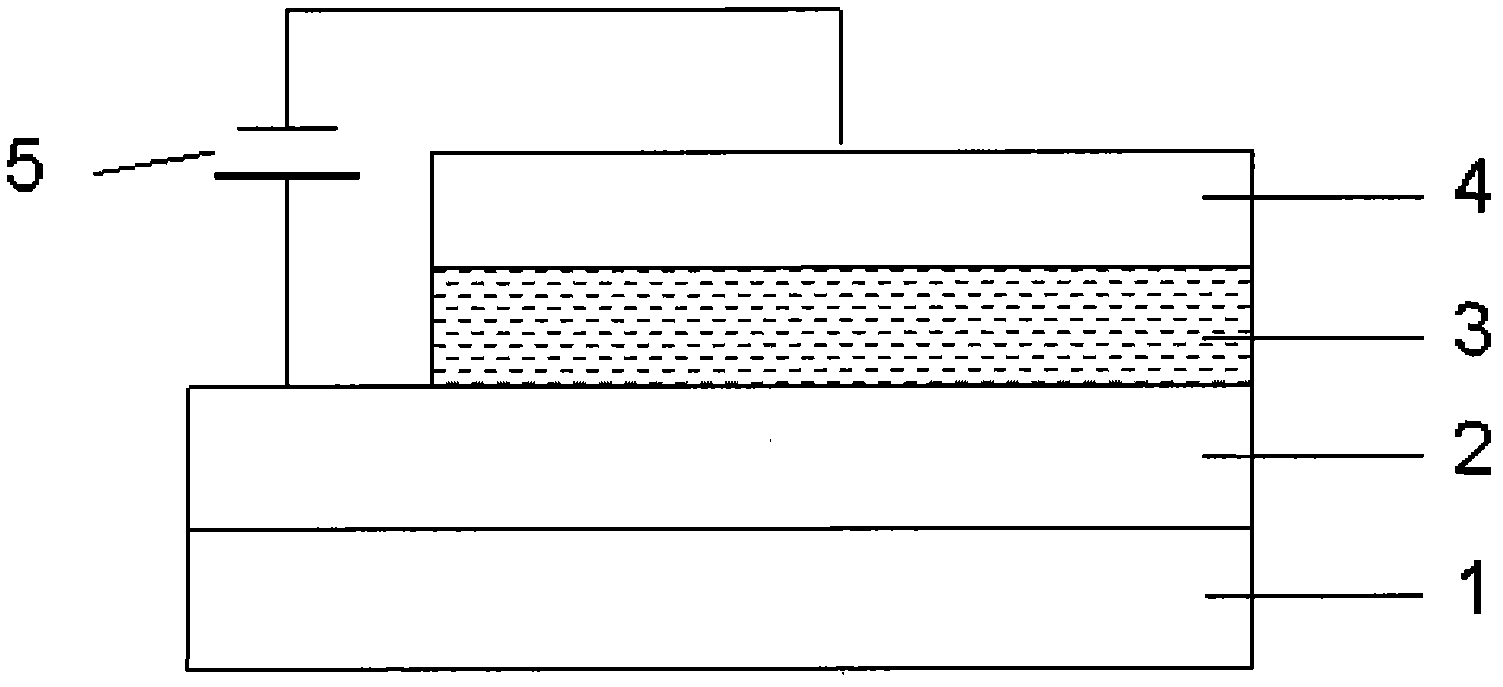

An electroluminescent device, white light technology, applied in the direction of electric solid device, semiconductor/solid state device manufacturing, electrical components, etc., can solve the problems of unfavorable carrier transport, high device turn-on voltage, difficulty in obtaining white light, etc. Efficiency, enhancing luminous intensity, suppressing annihilation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

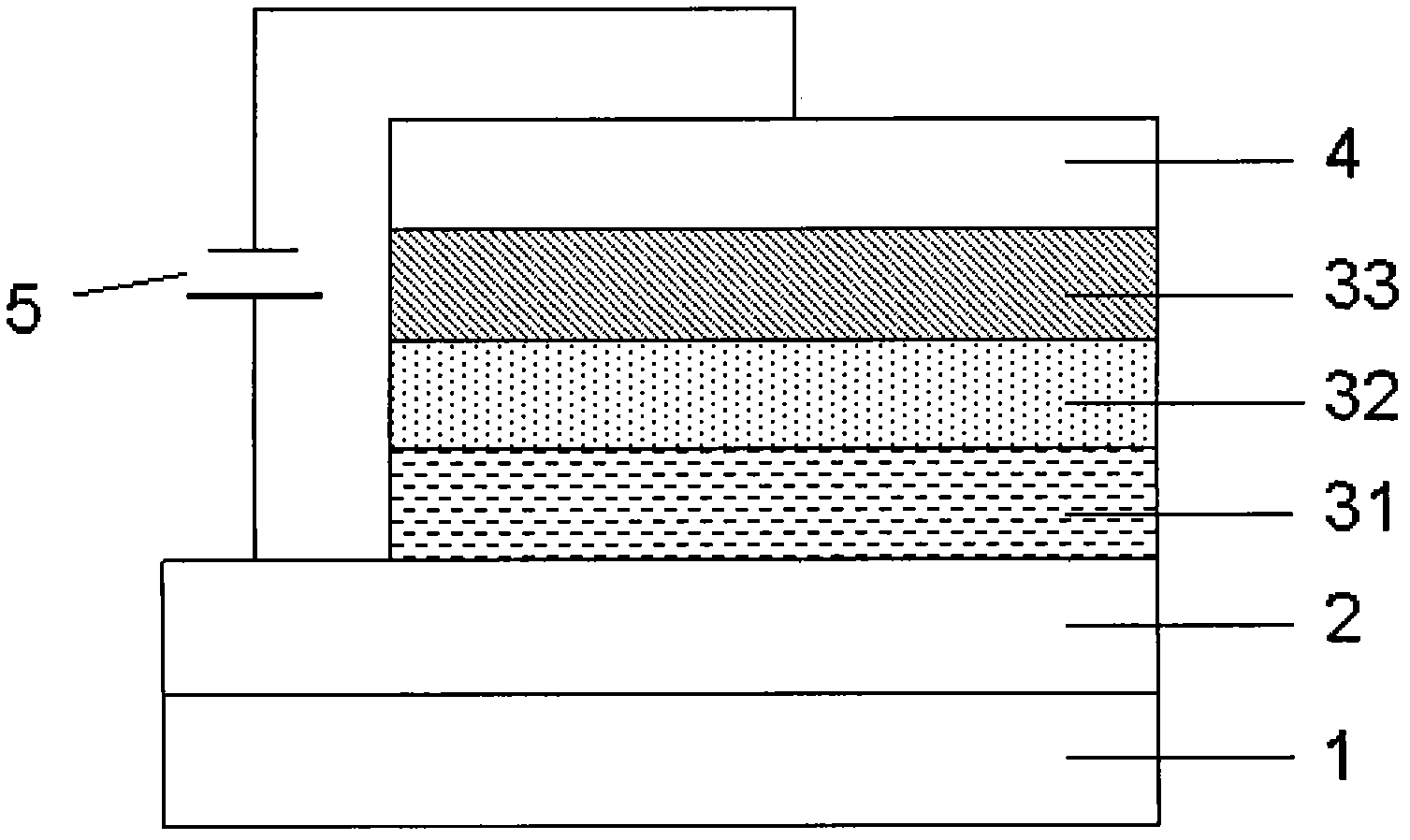

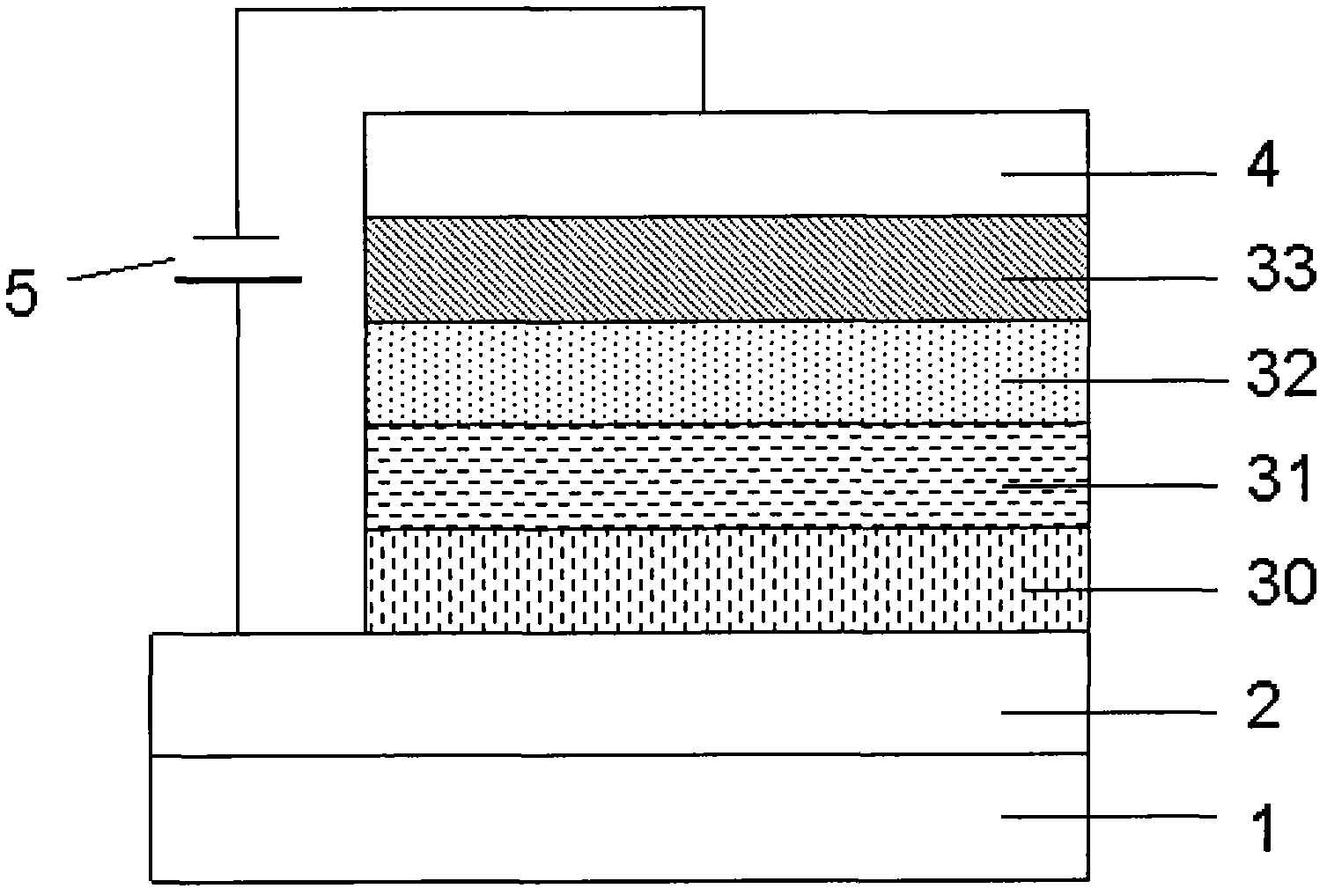

[0051] Such as figure 2 As shown, the blue phosphorescent light-emitting layer 31 of the device selects blue phosphorescent material Firpic doped mCP, and the complementary phosphorescent light-emitting layer 32 selects yellow phosphorescent dye (t-bt). 2 Ir(acac) is doped with BPhen, the material of the electron transport layer 33 is BPhen, and the cathode layer 4 is made of Mg:Ag alloy and Ag. The whole device structure is described as:

[0052] Glass / ITO / mCP:Firpic(20nm) / BPhen:(t-bt) 2 Ir(acac)(15nm) / BPhen(40nm) / Mg:Ag(200nm) / Ag(10nm)

[0053] The preparation method is as follows:

[0054] ①Using detergent, deionized water, acetone solution and ethanol solution to ultrasonically clean the glass substrate and the transparent conductive film ITO on it, and then dry it with high-purity nitrogen after cleaning. The ITO film on the glass substrate is used as the anode layer of the device. The sheet resistance of the ITO film is 10Ω / sq and the film thickness is 180nm.

[0055] ②Move the...

Embodiment 2

[0061] Such as figure 2 As shown, the blue phosphorescent light-emitting layer 31 of the device selects blue phosphorescent material Firpic doped mCP, and the complementary phosphorescent light-emitting layer 32 selects green phosphorescent dye (tpbi). 2 Ir(acac) is doped with BPhen, the material of the electron transport layer 33 is BPhen, and the cathode layer 4 is made of Mg:Ag alloy and Ag. The whole device structure is described as:

[0062] Glass / ITO / mCP:Firpic(20nm) / BPhen:(t-bt) 2 Ir(acac)(15nm) / BPhen(40nm) / Mg:Ag(200nm) / Ag(10nm)

[0063] The preparation process of the device is similar to Example 1.

Embodiment 3

[0065] Such as figure 2 As shown, the blue phosphorescent light-emitting layer 31 of the device selects blue phosphorescent material Firpic doped mCP, the complementary phosphorescent light-emitting layer 32 selects red phosphorescent dye PQIr doped BPhen, the electron transport layer 33 material is BPhen, and the cathode layer 4 uses Mg:Ag. Alloy and Ag. The whole device structure is described as:

[0066] Glass / ITO / mCP:Firpic(20nm) / BPhen:PQIr(15nm) / BPhen(40nm) / Mg:Ag(200nm) / Ag(10nm)

[0067] The preparation process of the device is similar to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sheet resistance | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com