Preparation method of independent and ordered titanium dioxide nanotube arrays among tubes

A nanotube array and titanium dioxide technology is applied in the field of preparation of nanotube arrays, which can solve the problems of reducing the specific surface area of the product, damage to the inner and outer walls of the nanotube, reducing the use value of the product, etc., achieving uniform structure distribution, simple and easy process operation, excellent Effects of Photocatalytic and Photovoltaic Properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The concrete steps of preparation are:

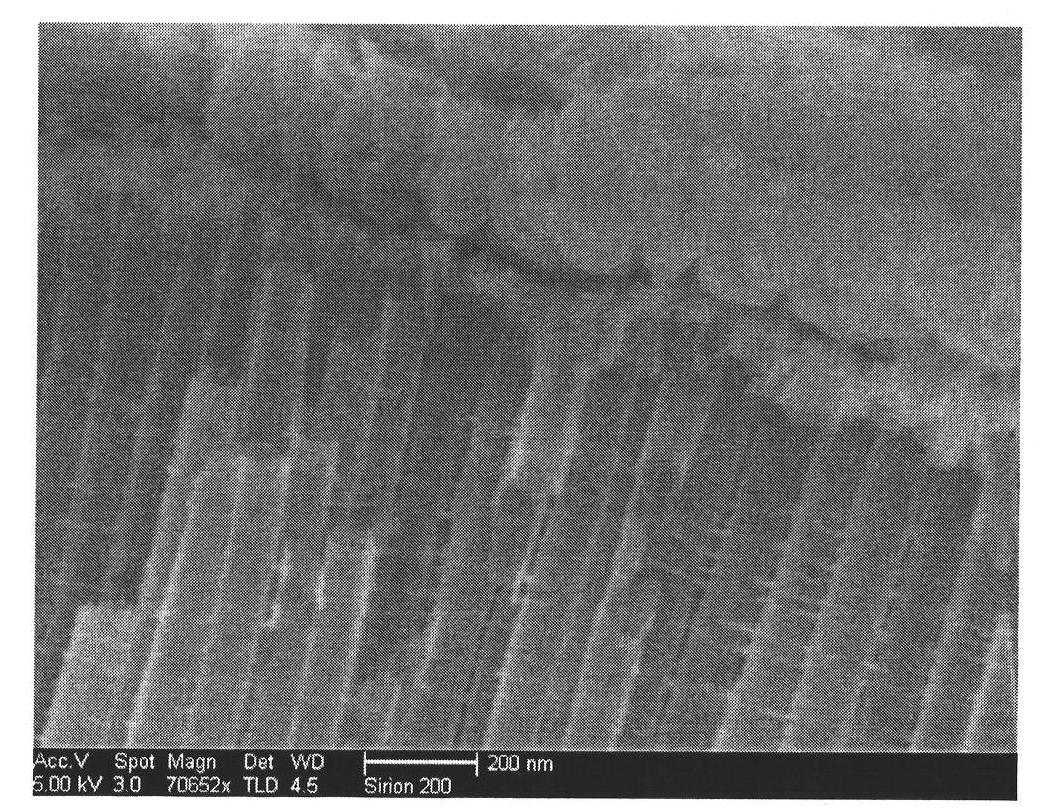

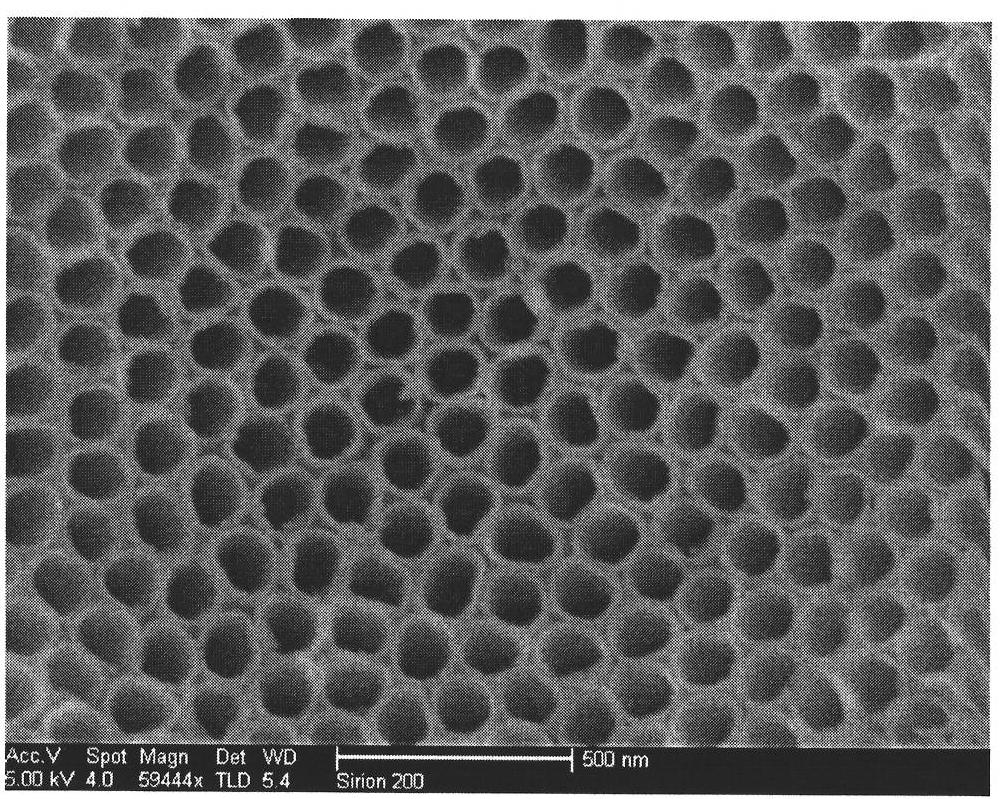

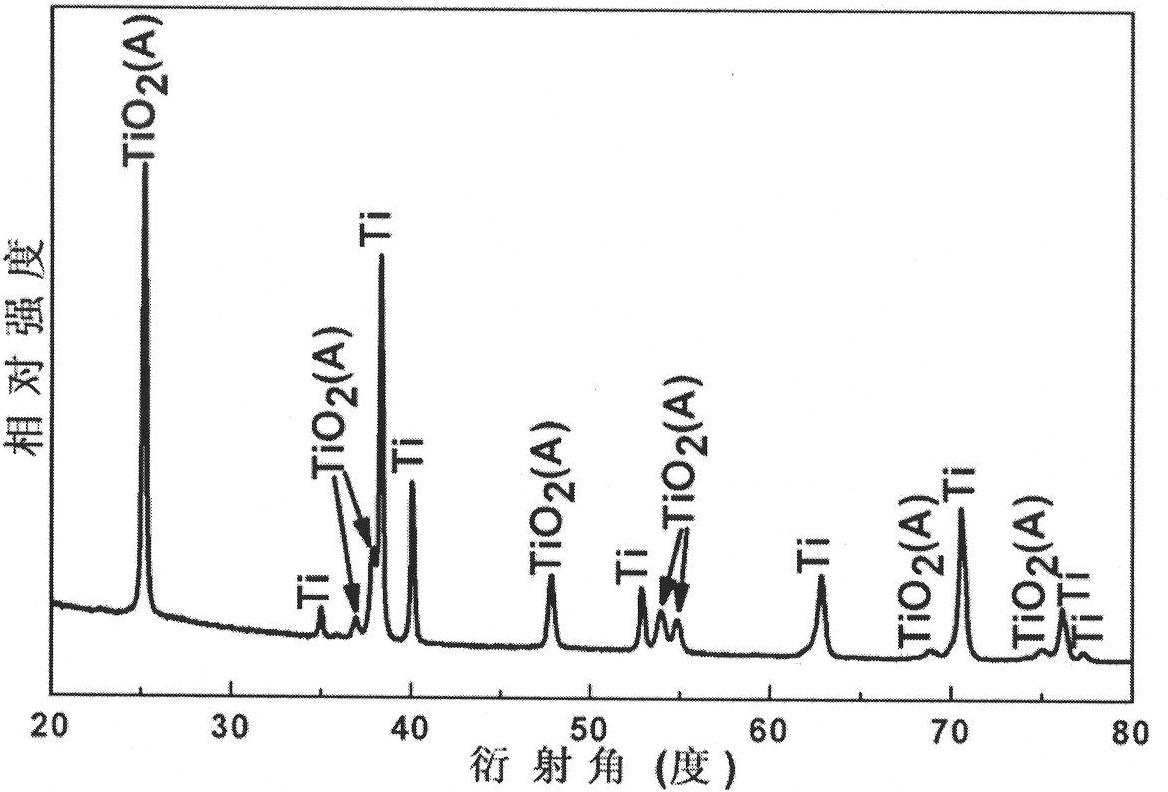

[0020] Step 1, first put the metal titanium sheet as an anode in a water-based electrolyte solution with a stirring temperature of 25°C, ammonium fluoride, sulfuric acid and water with a molar ratio of 0.12:1.6:48, and adjust the DC voltage to 0.8V / The rate of s was increased from 0V to 20V and kept for 25 minutes, and then the metal titanium sheet that had been anodized for the first time was taken out and washed with water; after that, the metal titanium sheet that had been anodized and cleaned for the first time was used as an anode and placed at a temperature of 25°C , in an organic electrolyte with a molar ratio of ammonium fluoride, water and ethylene glycol of 0.06:1.09:15.5, adjust the DC voltage to rise from 0V to 60V at a rate of 0.8V / s and keep it for 1h; wherein, the metal titanium sheet The purity is 99.9%. The water in the water-based electrolyte and organic electrolyte, as well as the water for cleaning the first ...

Embodiment 2

[0023] The concrete steps of preparation are:

[0024] Step 1, first put the metal titanium sheet as an anode in a water-based electrolyte solution with a stirring temperature of 28 ° C, ammonium fluoride, sulfuric acid and water with a molar ratio of 0.13:1.7:49, and adjust the DC voltage to 0.9V / The rate of s was raised from 0V to 20V and kept for 26 minutes, and then the metal titanium sheet that had been anodized for the first time was taken out and washed with water; after that, the metal titanium sheet that had been anodized and cleaned for the first time was used as an anode and placed at a temperature of 28°C , in an organic electrolyte with a molar ratio of ammonium fluoride, water and ethylene glycol of 0.07:1.1:16.5, adjust the DC voltage to rise from 0V to 60V at a rate of 0.9V / s and keep it for 1.1h; among them, the metal titanium sheet The purity is 99.99%. The water in the water-based electrolyte and organic electrolyte, as well as the water used to clean the f...

Embodiment 3

[0027] The concrete steps of preparation are:

[0028] Step 1, first put the metal titanium sheet as the anode in the water-based electrolyte with the molar ratio of ammonium fluoride, sulfuric acid and water at 30°C under stirring, and adjust the DC voltage at 1V / s The rate is raised from 0V to 20V and kept for 27 minutes, and then the metal titanium sheet that has been anodized for the first time is taken out and washed with water; after that, the metal titanium sheet that has been anodized and cleaned for the first time is placed as an anode at a temperature of 30°C. Ammonium fluoride, water and ethylene glycol in the organic electrolyte with a molar ratio of 0.08:1.15:17.5, adjust the DC voltage from 0V to 60V at a rate of 1V / s and keep it for 1.2h; wherein, the purity of the titanium sheet 99.9%, the water in the water-based electrolyte and organic electrolyte, and the water used to clean the first anodized titanium sheet are deionized water, and the counter electrodes fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com