Modified poly-m-phenylene isophthalamide ultrafiltration membrane and preparation method and application thereof

A poly-m-phenylene isophthalamide, ultrafiltration membrane technology, applied in ultrafiltration, chemical instruments and methods, membranes, etc., can solve the problem of membrane anti-pollution level decline, precipitation and leakage of water safety threats, membrane affinity Water quality reduction and other issues to achieve the effect of inhibiting leakage trend, high retention capacity and permeability, and enhanced connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

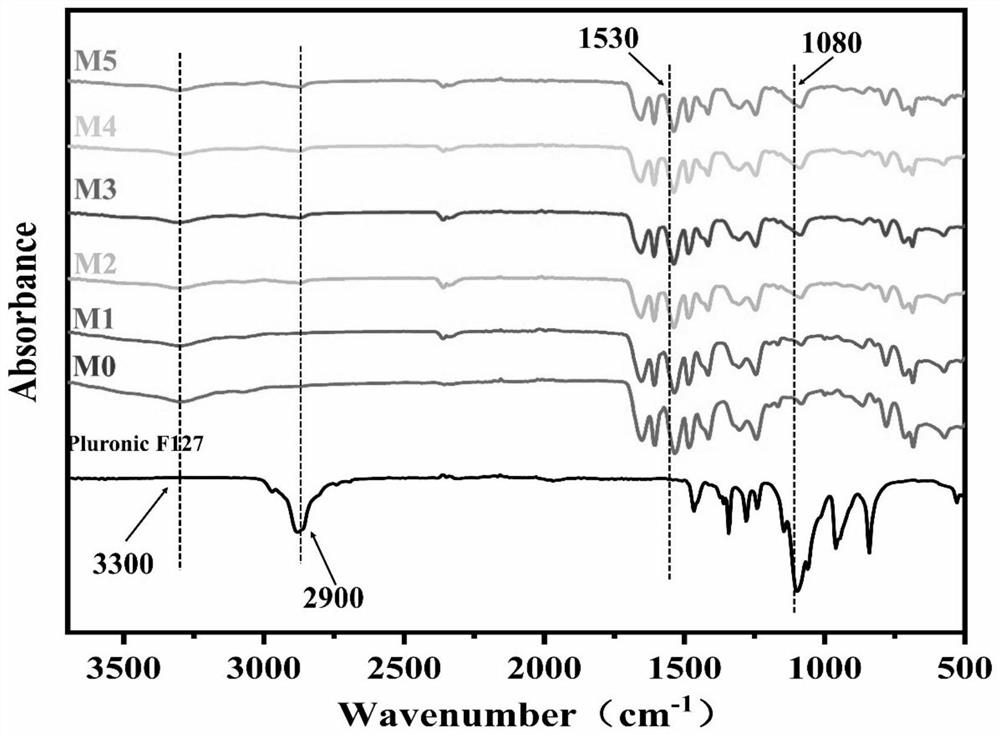

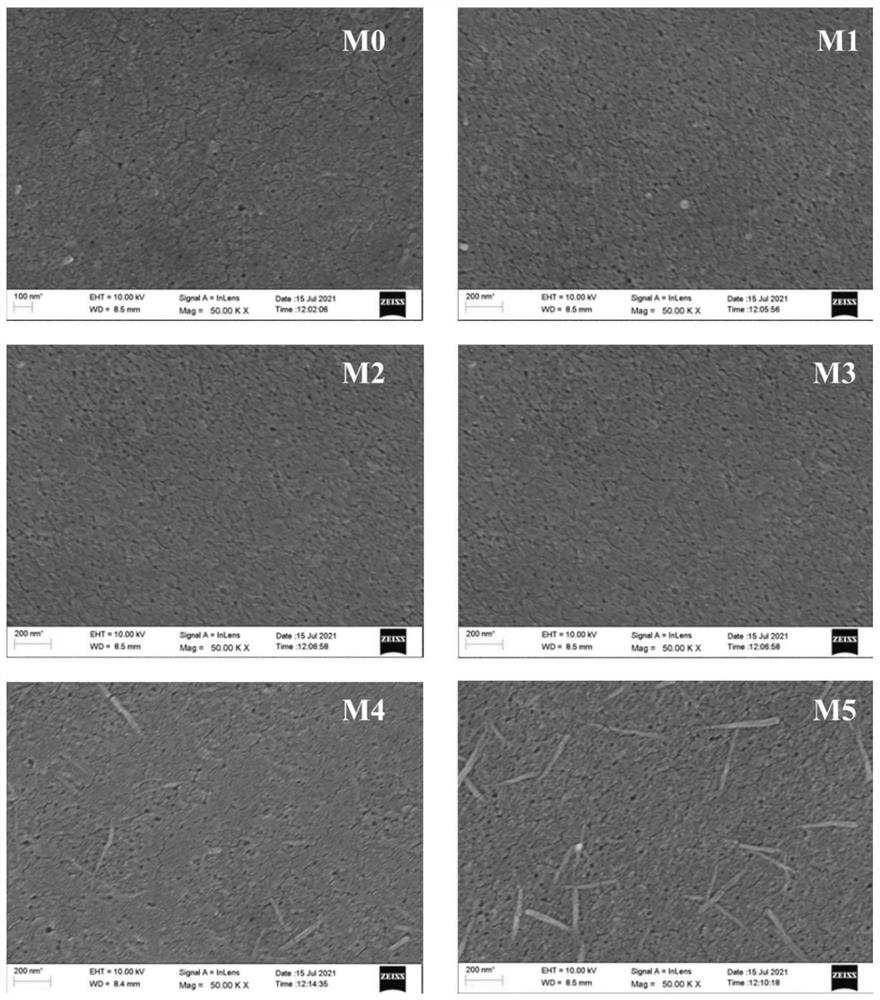

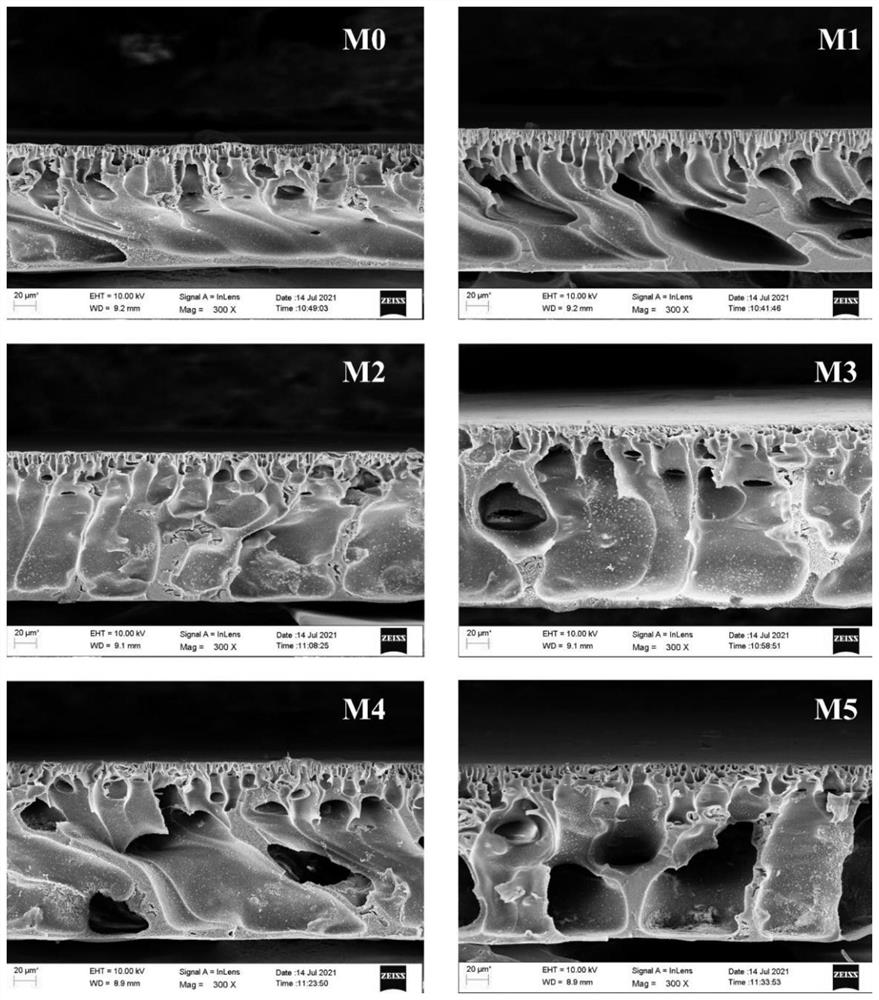

[0056] At room temperature, 5 wt. % lithium chloride and 82.5 wt. % DMAc solvent were mixed and dissolved with high-speed stirring to form a transparent homogeneous solution. Add 0.5wt.% of Pluronic F127 to the transparent homogeneous solution and continue to stir until it dissolves into a uniform and stable mixed solution, then add 12wt.% of PMIA to the mixed solution, and stir at a high speed at 45 ℃ to fully dissolve, After a uniform and stable casting solution is formed, the temperature is lowered to 25°C and left to stand for defoaming. After the defoaming is completed, the membrane is formed by a non-solvent induced phase separation method.

[0057] The specific film forming method is: use a glass rod to scrape the film on a smooth flat glass plate, the thickness is controlled at 200 microns, after scraping the film, stay in the air with a humidity of 10%-80% for 5-60 seconds, and then The new PMIA flat membrane was immersed in a sodium sulfate salt solution at a temper...

Embodiment 2

[0059] At room temperature, 5 wt.% lithium chloride and 82.0 wt.% DMAc solvent were mixed and dissolved with high-speed stirring to form a transparent homogeneous solution. Add 1.0wt.% of Pluronic F127 to the transparent homogeneous solution and continue to stir until it dissolves into a uniform and stable mixed solution, then add 12wt.% of PMIA to the mixed solution and stir at 85°C to fully dissolve at high speed. After a uniform and stable casting solution is formed, the temperature is lowered to 25°C and left to stand for defoaming. After the defoaming is completed, the membrane is formed by a non-solvent induced phase separation method.

[0060] The specific film forming method is: use a glass rod to scrape the film on a smooth flat glass plate, the thickness is controlled at 200 microns, after scraping the film, stay in the air with a humidity of 10%-80% for 5-60 seconds, and then The nascent PMIA flat membrane was immersed in a saturated sodium chloride solution at a t...

Embodiment 3

[0062] At room temperature, 5 wt.% lithium chloride and 81.5 wt.% DMAc solvent were mixed and dissolved with high-speed stirring to form a transparent homogeneous solution. Add 1.5wt.% of Pluronic F127 to the transparent homogeneous solution and continue to stir until it dissolves into a uniform and stable mixed solution, then add 12wt.% of PMIA to the mixed solution, and stir at 85°C to fully dissolve at high speed. After a uniform and stable casting solution is formed, the temperature is lowered to 25°C and left to stand for defoaming. After the defoaming is completed, the membrane is formed by a non-solvent induced phase separation method.

[0063] The specific film forming method is: use a glass rod to scrape the film on a smooth flat glass plate, the thickness is controlled at 200 microns, after scraping the film, stay in the air with a humidity of 10%-80% for 5-60 seconds, and then The nascent PMIA flat membrane was immersed in a saturated sodium chloride solution at a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com