Method for preparing long-lasting antibacterial polyacrylate emulsion

A polyacrylic acid emulsion, long-lasting technology, applied in the direction of coating, etc., can solve the problems of poor emulsion stability, large emulsion particle size, difficult to filter, etc., and achieve the effects of durable antibacterial, high water absorption, and good freeze-thaw resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

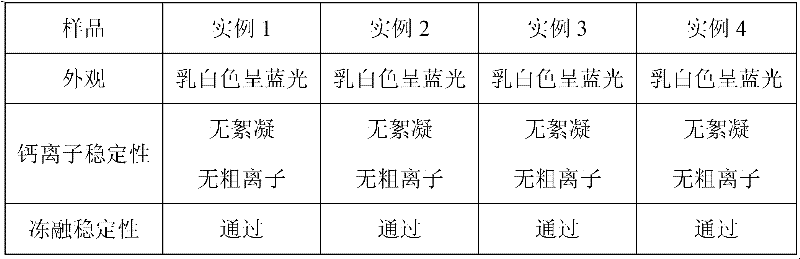

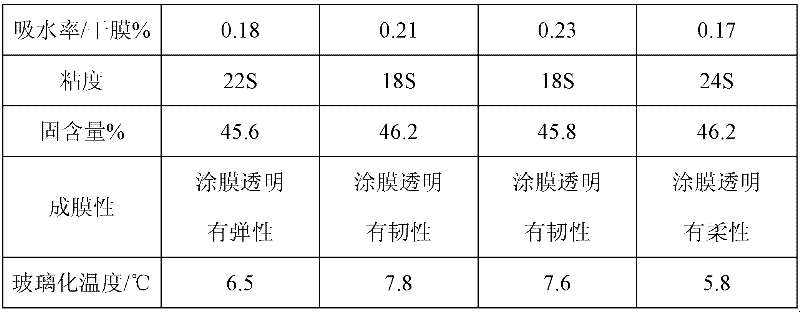

Examples

Embodiment 1

[0045] 1) Add 30 parts of deionized water, 2 parts of AMC12AB-AEO15 emulsifier, methyl methacrylate and butyl acrylate into a four-port reaction vessel equipped with a speed-adjustable stirrer, reflux tube, dropping funnel and thermometer 10 parts of mixed monomers, 1.7 parts of acrylic acid monomers, 1 part of acrylamide monomers, 2 parts of β-hydroxyethyl acrylate monomers, 1.05 parts of pH buffer solution; heat up and emulsify under high-speed stirring at 1200-1300rpm to obtain milky white Pre-emulsified mixed monomer emulsion;

[0046] 2) When the temperature rises to 75°C, reduce the speed to 800rpm, add 0.05 parts of initiator dropwise, and when the temperature rises to 80°C, the reaction is initiated, and blue light appears; Note: The initiator is pre-prepared with 5% aqueous solution

[0047] 3) When there is no reflux in the reaction, add the remaining mixed monomer and initiator solution dropwise at the same time, keep the temperature at 81-83° C., and finish droppin...

Embodiment 2

[0049]1) Add 30 parts of deionized water, 2.05 parts of AMC12AB-AEO15 emulsifier, methyl methacrylate and butyl acrylate into a four-port reaction vessel equipped with a speed-adjustable stirrer, reflux tube, dropping funnel and thermometer 10 parts of mixed monomer, 1.8 parts of acrylic acid monomer, 1 part of acrylamide monomer, 2 parts of β-hydroxyethyl acrylate monomer, 2 parts of allyl glycidyl ether, 1.06 parts of pH buffer solution; ~1300rpm high-speed stirring to emulsify to obtain a milky white pre-emulsified mixed monomer emulsion;

[0050] 2) When the temperature rises to 75°C, reduce the speed to 800rpm, add 0.06 parts of initiator dropwise, and when the temperature rises to 80°C, the reaction is initiated, and blue light appears; Note: The initiator is pre-prepared with 5% aqueous solution

[0051] Step 3) Referring to Example 1, the milky white liquid with a solid content of 46.2% was obtained.

Embodiment 3

[0053] 1) Add 30 parts of deionized water, 2.05 parts of AMC12AB-AEO15 emulsifier, methyl methacrylate and butyl acrylate into a four-port reaction vessel equipped with a speed-adjustable stirrer, reflux tube, dropping funnel and thermometer 10 parts of mixed monomer, 1.8 parts of acrylic acid monomer, 1 part of acrylamide monomer, 2 parts of β-hydroxyethyl acrylate monomer, 2 parts of glycidyl methacrylate, 1.06 parts of pH buffer solution; ~1300rpm high-speed stirring to emulsify to obtain a milky white pre-emulsified mixed monomer emulsion;

[0054] 2) When the temperature rises to 75°C, reduce the speed to 800rpm, add 0.06 parts of initiator dropwise, and when the temperature rises to 80°C, the reaction is initiated, and blue light appears; Note: The initiator is pre-prepared with 5% aqueous solution

[0055] Step 3) Referring to Example 1, the milky white liquid with a solid content of 45.8% was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com