Silicon carbide foamed ceramics corrugated structured packing and preparation method and applications thereof

A foamed ceramic and structured packing technology, applied in ceramic products, chemical instruments and methods, applications, etc., can solve the problems of high equipment construction and maintenance costs, low service life, unfavorable energy saving, etc. The effect of reducing and saving maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

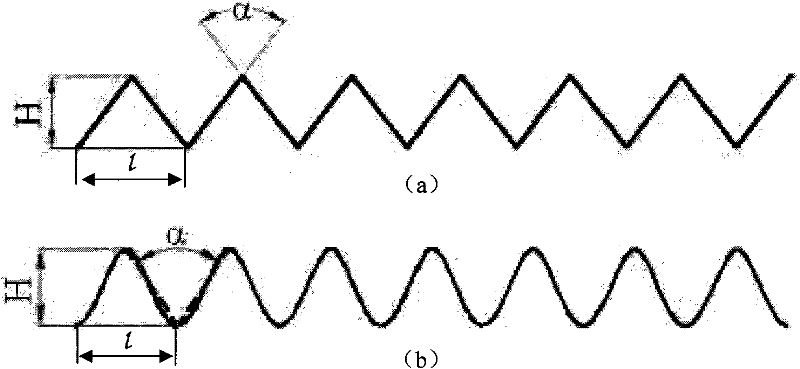

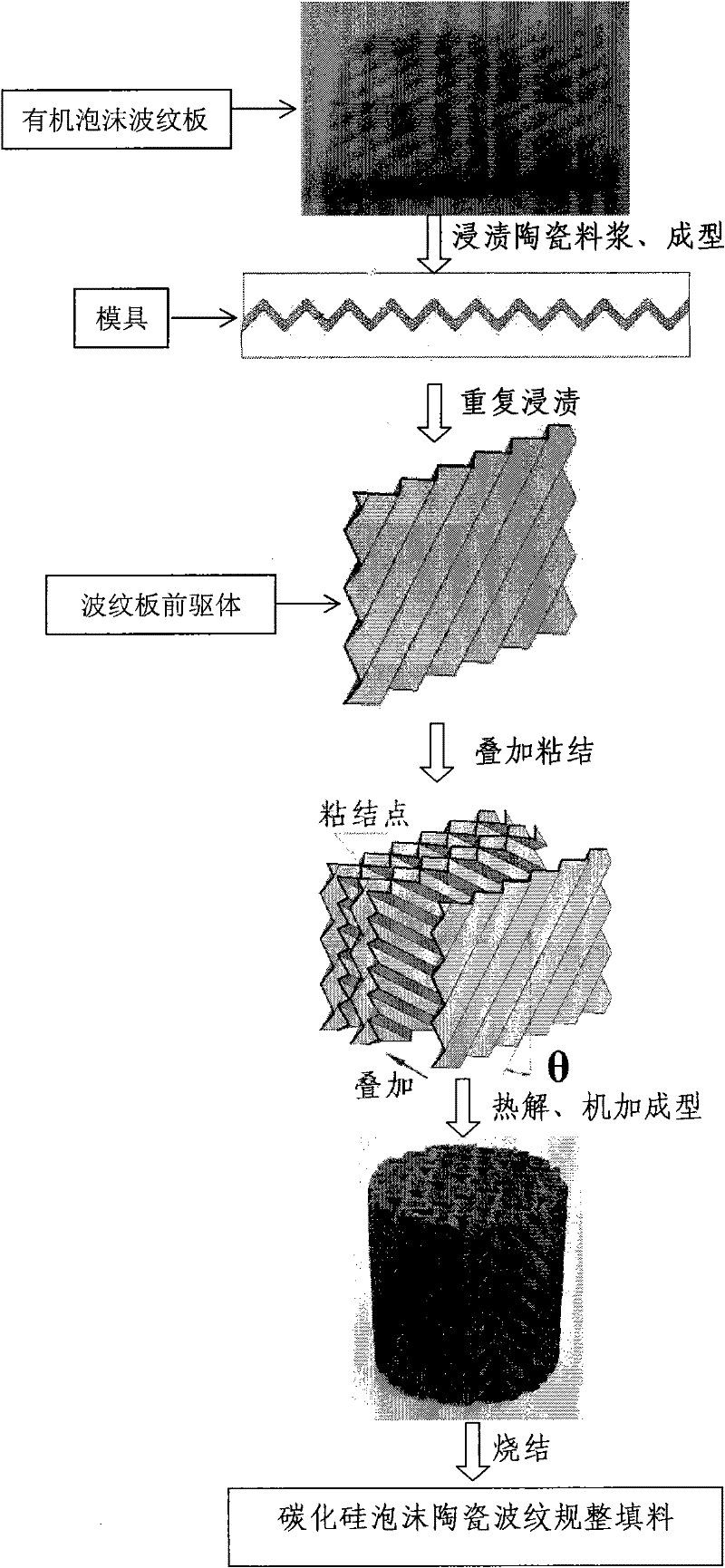

[0040] Firstly, using silicon carbide foam ceramics as the material, according to the corresponding geometric characteristics (see Table 1), the polyurethane sponge foam is pre-cut into the required corrugated shape, and then the silicon carbide foam ceramic filler unit plate precursor is prepared. Then, the same kind of slurry is used as the adhesive, bonded according to the structure requirements of the structured packing, then pyrolyzed, machined, and sintered to obtain a new type of silicon carbide foam ceramic corrugated structured packing. The packing disc diameter is 100mm, and the disc height is 100mm.

[0041] In the silicon carbide foam ceramic corrugated structured packing of the present invention, the packing units thereof are connected at one time to form a packing disc during the preparation process of the foam ceramic corrugated plate, which is firm in combination, easy to install and stable in structure. The connection process is as follows: after the precursor...

Embodiment 2

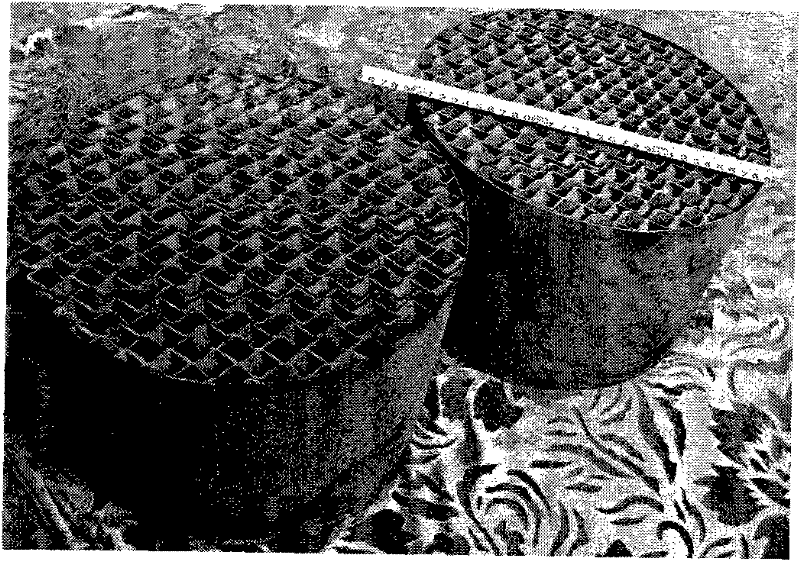

[0058] Preparation of Φ315×200mm silicon carbide foam ceramic corrugated type II structured packing ( image 3 ), carried out the pilot-scale scale-up experiment on the pilot-scale rectifying tower, and compared with the wire mesh BX structured packing (material is 316L), the experimental material adopted is 10wt% alcohol aqueous solution, and the height of both packings is 2 meters , Total reflux operation, the results show that the theoretical plate number of BX structured packing is 2.9 pieces / m, while the silicon carbide foam ceramic corrugated type II structured packing can reach 5.1 pieces / m, an increase of more than 75%.

Embodiment 3

[0060] (1) Using HCl acid as the medium to study and compare the corrosion resistance of the material, configure three different concentrations of HCl acid solution (5wt%, 10wt%, 25wt%), take silicon carbide foam ceramic corrugated structured packing and After the BX packing (316L) was soaked in three different concentrations of solutions for three weeks, the mass change rate before and after was measured, showing that no corrosion signs were found in the silicon carbide foam ceramic corrugated structured packing, while the BX packing (316L) lost weight obviously, and the local area Has been rotten, and even holes.

[0061] (2) Using H 2 SO 4 Acid was used as the medium to study and compare the corrosion resistance of materials, and three different concentrations of H 2 SO 4 Acid solution (respectively 5wt%, 20wt%, 35wt%), silicon carbide foam ceramic corrugated structured packing and BX packing (316L) were soaked in three different concentration solutions for three weeks, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com