Glue for nuclear-radiation shielding lead garment and production method thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

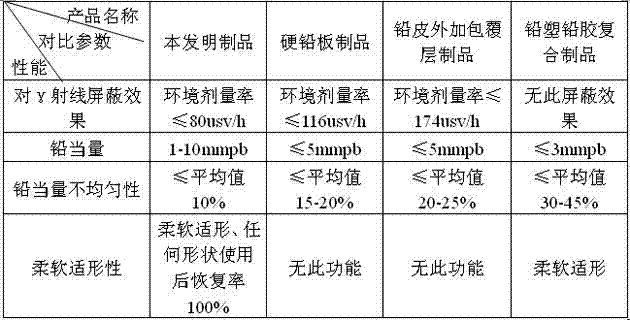

Image

Examples

Embodiment Construction

[0013] 1. Weighing

[0014] Weigh 10000g of natural rubber, 110-120g of accelerator, 500g of zinc oxide, 80g of stearic acid, 50g of antioxidant, 200g of rosin, 2000g of light calcium carbonate, 210g of sulfur, and 5000g of gasoline.

[0015] 2. Melting

[0016] After mixing the above raw materials, put them into the melting furnace and heat until all the raw materials are completely melted to form a glue, which is heat-insulated and sealed for use.

[0017] 3. Making lead core

[0018] 1) Evenly lay lead fiber filaments in the wooden mold, and form lead fiber filament sheets by pressing;

[0019] 2) Take out the shaped lead fiber sheet, and spray the glue on the lead fiber sheet;

[0020] 3) Put the lead fiber flakes sprayed with glue into the metal mold, place them in a high-temperature vulcanizer at 160-200°C, under a vulcanization pressure of 300kg, and after 350-450 seconds, cool to room temperature and take out the vulcanized chips .

[0021] 4. Sew the chip into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com