Automatic staining instrument with Gram staining two-step method

A Gram dyeing and dyeing machine technology, applied in the field of automatic dyeing machines, can solve problems such as complicated operation, and achieve the effect of strong continuity, friendly interface and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

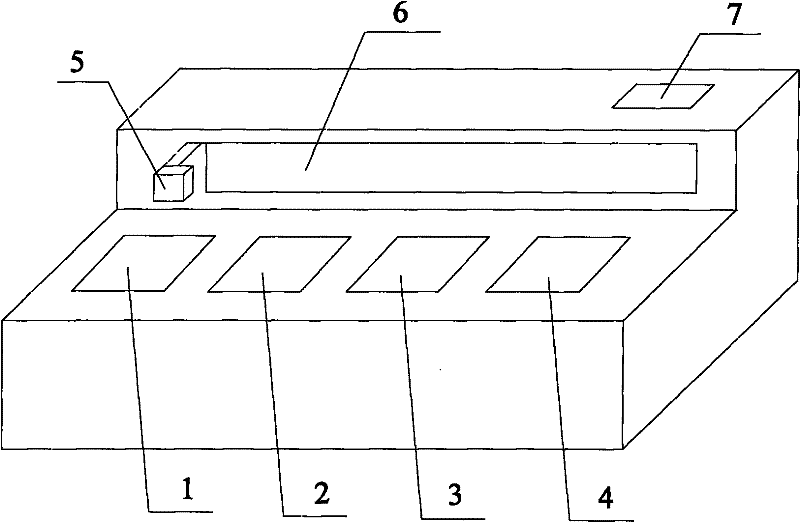

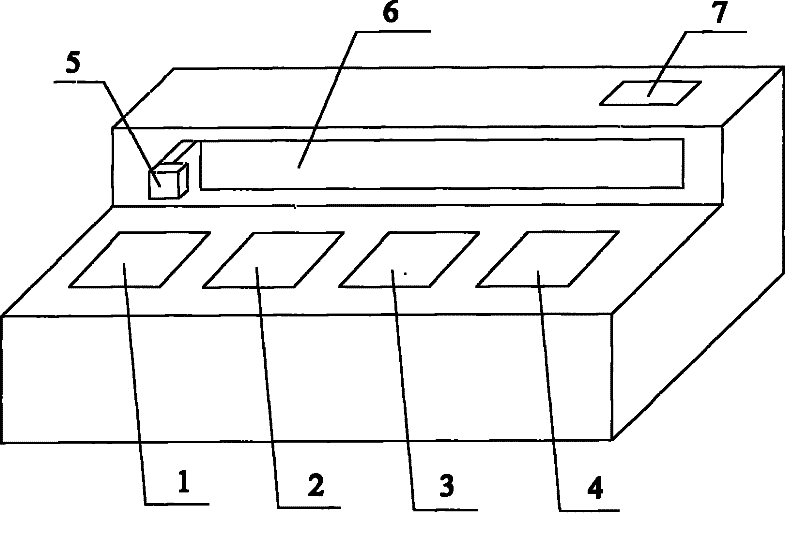

[0038] A two-step automatic staining instrument for gram staining, its structure is as follows figure 1 Shown. The dyeing machine is composed of the first dyeing tank 1, the second dyeing tank 2, the cleaning tank 3, the warm air drying tank 4, the manipulator 5, the track 6 and the display screen 7. The first dyeing tank 1, the second dyeing tank 2, the cleaning The pool 3 and the warm air drying pool 4 are arranged in sequence in the front of the dyeing machine. The dye in the first dyeing tank 1 is a 0.5wt% crystal violet aqueous solution, and the dye in the second dyeing tank 2 is an ethanol solution of basic fuchsin, iodine and potassium iodide, in which the concentration of basic fuchsin is 0.3wt%, The concentration of iodine is 0.1wt%, and the concentration of potassium iodide is 0.6wt%. The overflow drainage through the cleaning tank 3 will not cause the overflow of dye liquor and environmental pollution during dyeing. The temperature in the heating drying tank 4 is 50...

Embodiment 2

[0041] A two-step automatic dyeing instrument for gram dyeing. The dyeing instrument is composed of a first dyeing tank, a second dyeing tank, a cleaning tank, a warm air drying tank, a manipulator, a track, and a display screen. The pool, the cleaning pool and the warm air drying pool are arranged in sequence in the front of the dyeing machine. The dye in the first dyeing tank is a 1.0wt% crystal violet aqueous solution, and the dye in the second dyeing tank is an ethanol solution of basic fuchsin, iodine and potassium iodide. The concentration of basic fuchsin is 0.2wt%, and the concentration of iodine is 0.1wt%, the concentration of potassium iodide is 0.4wt%, the overflow drain through the cleaning tank, during dyeing, will not cause the overflow of the dye solution and environmental pollution, the temperature in the heating flow drying tank is 50℃, without flame fixation and natural drying. The manipulator is set on the upper part of the dyeing machine. The front end of th...

Embodiment 3

[0044] A two-step automatic dyeing instrument for gram dyeing. The dyeing instrument is composed of a first dyeing tank, a second dyeing tank, a cleaning tank, a warm air drying tank, a manipulator, a track, and a display screen. The pool, the cleaning pool and the warm air drying pool are arranged in sequence in the front of the dyeing machine. The dye in the first dyeing tank is a 0.5wt% crystal violet aqueous solution, and the dye in the second dyeing tank is an ethanol solution of basic fuchsin, iodine and potassium iodide. The concentration of basic fuchsin is 0.4wt% and the concentration of iodine is 0.2wt%, the concentration of potassium iodide is 0.6wt%. The overflow drainage through the cleaning tank will not cause the overflow of dye liquor and environmental pollution during dyeing. The temperature in the heating flow drying tank is 60°C, without flame fixation and natural drying. The manipulator is set on the upper part of the dyeing machine. 24 sheets to be dyed are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com