Manufacturing method of creeping-resisting aluminium alloy conductor interlocking armoring optical-fiber composite low-voltage cable

A technology of aluminum alloy conductors and interlocking armor, which is used in cable/conductor manufacturing, circuits, electrical components, etc., and can solve problems such as increasing product cost, increasing construction cost, and increasing the overall weight of the cable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

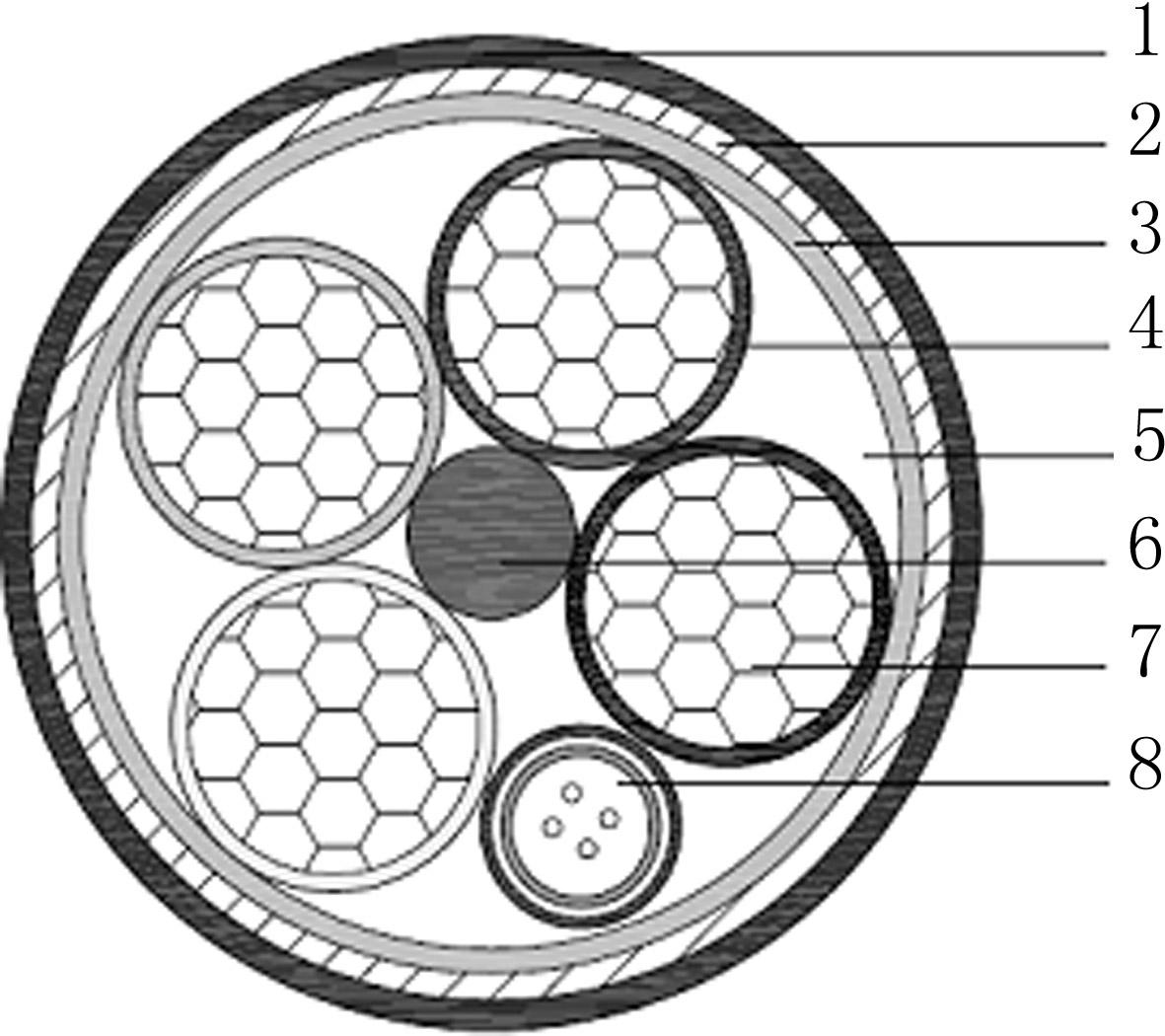

[0054] according to figure 1, 4 As shown, a method for manufacturing a creep-resistant aluminum alloy conductor interlocking armored optical fiber composite low-voltage cable, the steps are as follows:

[0055] ⑴Creep-resistant aluminum alloy is melted to manufacture aluminum alloy rods, and its aluminum alloy composition weight percentage is: Si 0.09, Fe 0.75, Cu 0.28, Mg 0.045, Zn 0.045, B 0.035, Al 98.755;

[0056] ⑵The aluminum alloy rod is made into a circular single wire of the required specification through a multi-channel circular hole die drawing process;

[0057] (3) After two or more special-shaped wire drawing dies, the special-shaped aluminum single wire of the required size is drawn;

[0058] (4) Quenching and tempering heat treatment of special-shaped aluminum single wire to obtain special-shaped soft aluminum single wire;

[0059] ⑸ Twisting multiple special-shaped soft aluminum single wires on a stranding machine to complete the conductive core;

[0060] ...

Embodiment 2

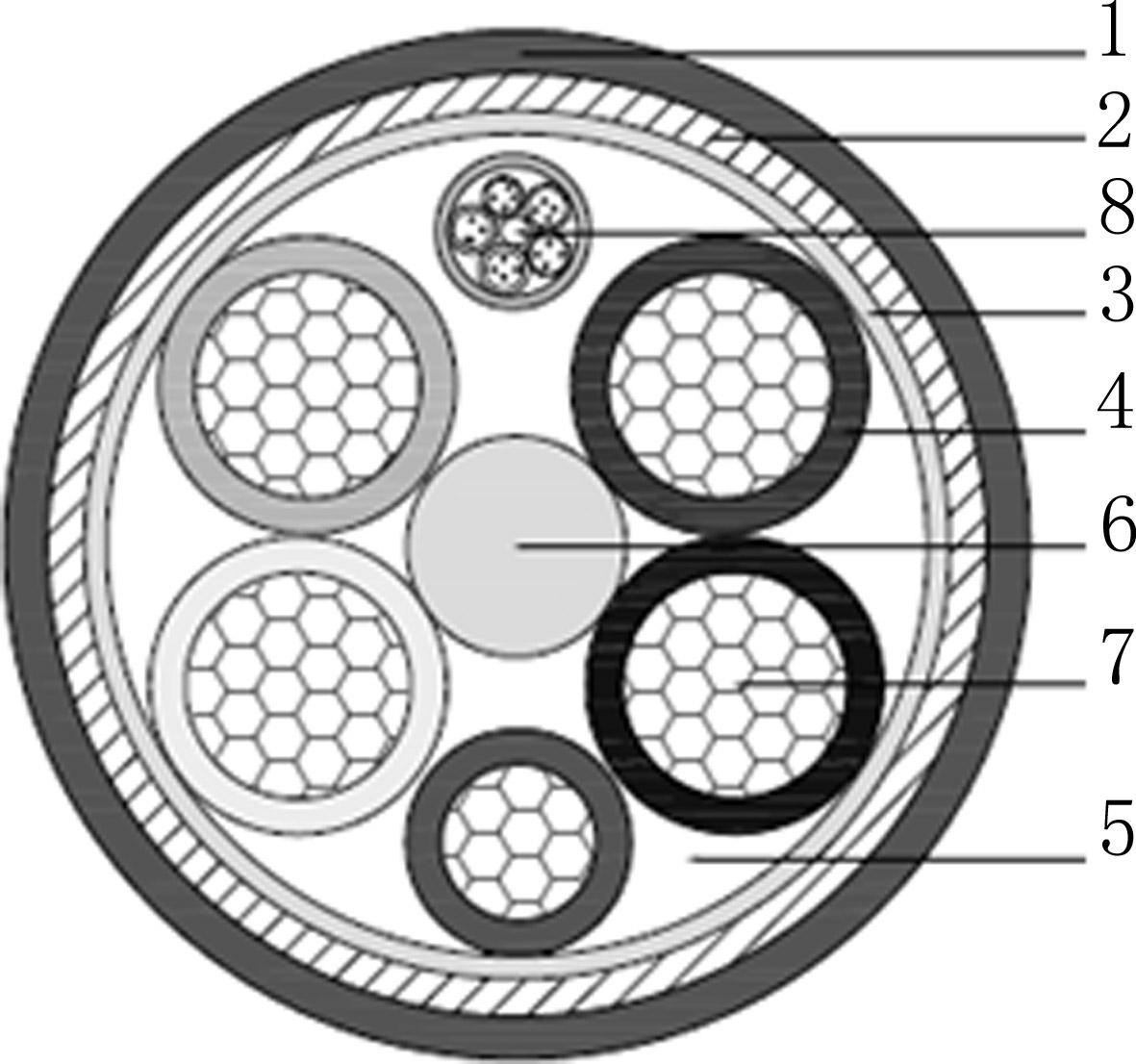

[0075] according to figure 2 , 4 As shown, a method for manufacturing a creep-resistant aluminum alloy conductor interlocking armored optical fiber composite low-voltage cable, the steps are as follows:

[0076] ⑴Creep-resistant aluminum alloy is melted to manufacture aluminum alloy rods, and its aluminum alloy composition weight percentage is: Si 0.02, Fe 0.33, Cu 0.18, Mg 0.01, Zn 0.016, B 0.04, Al 99.44;

[0077] ⑵The aluminum alloy rod is made into a circular single wire of the required specification through a multi-channel circular hole die drawing process;

[0078] (3) After two or more special-shaped wire drawing dies, the special-shaped aluminum single wire of the required size is drawn;

[0079] (4) Quenching and tempering heat treatment of special-shaped aluminum single wire to obtain special-shaped soft aluminum single wire;

[0080] ⑸ Twisting multiple special-shaped soft aluminum single wires on a stranding machine to complete the conductive core;

[0081] ⑹ ...

Embodiment 3

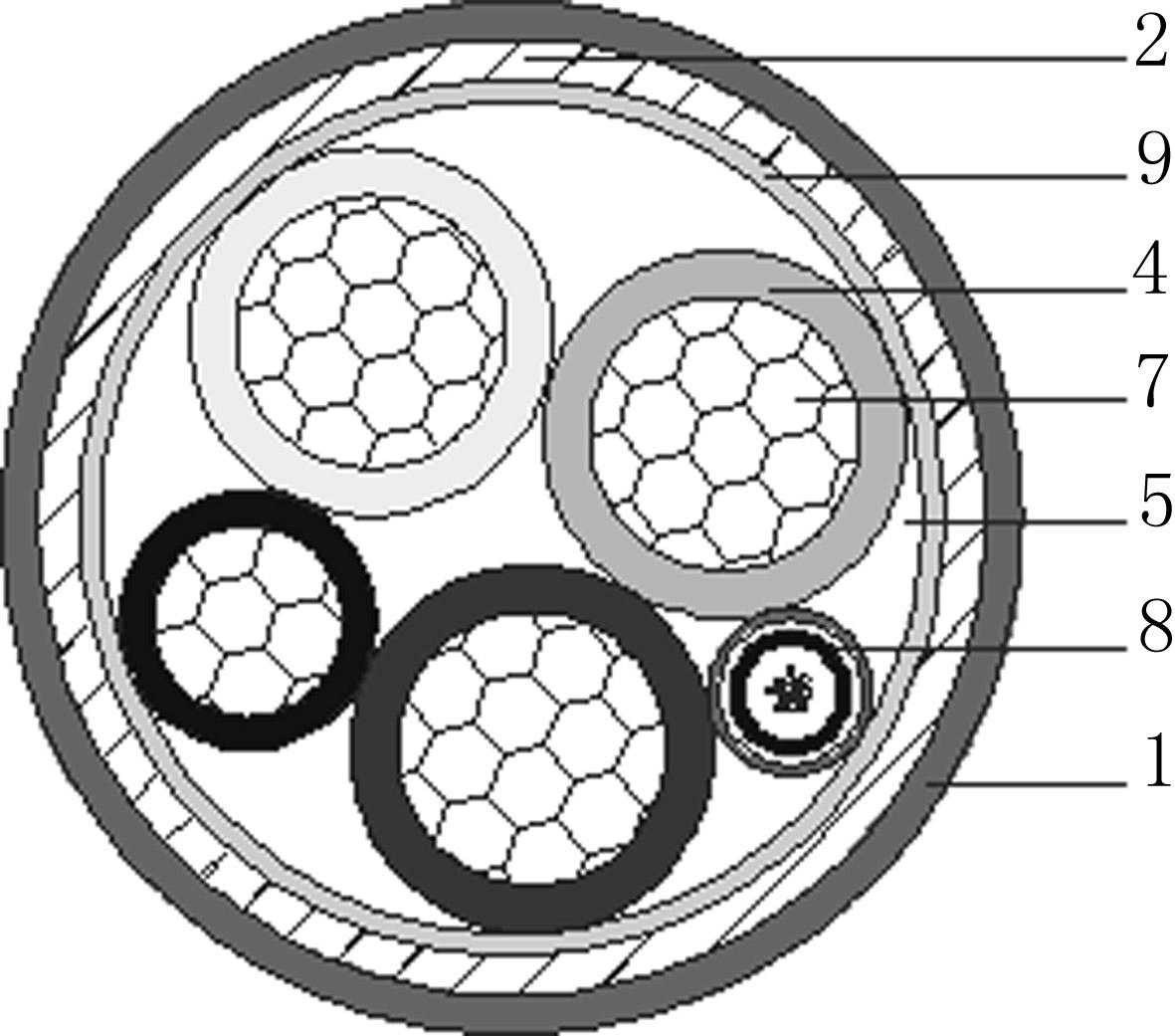

[0096] according to image 3 , 4 As shown, a method for manufacturing a creep-resistant aluminum alloy conductor interlocking armored optical fiber composite low-voltage cable, the steps are as follows:

[0097] ⑴Creep-resistant aluminum alloy is melted to manufacture aluminum alloy rods, and its aluminum alloy composition weight percentage is: Si 0.05, Fe 0.55, Cu 0.23, Mg 0.025, Zn 0.025, B 0.02, Al 99.1;

[0098] ⑵The aluminum alloy rod is made into a circular single wire of the required specification through a multi-channel circular hole die drawing process;

[0099] (3) After two or more special-shaped wire drawing dies, the special-shaped aluminum single wire of the required size is drawn;

[0100] (4) Quenching and tempering heat treatment of special-shaped aluminum single wire to obtain special-shaped soft aluminum single wire;

[0101] ⑸ Twisting multiple special-shaped soft aluminum single wires on a stranding machine to complete the conductive core;

[0102] ⑹ e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com