Catalytic materials, photoanodes, and photoelectrochemical cells for water electrolysis and other electrochemical techniques

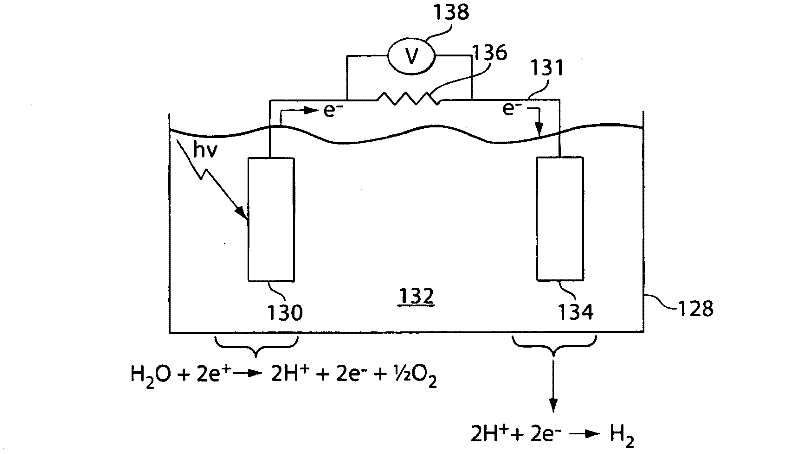

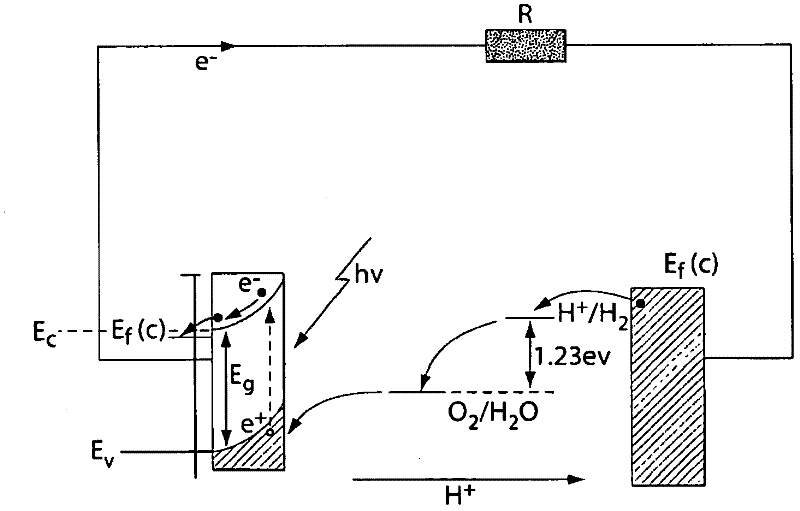

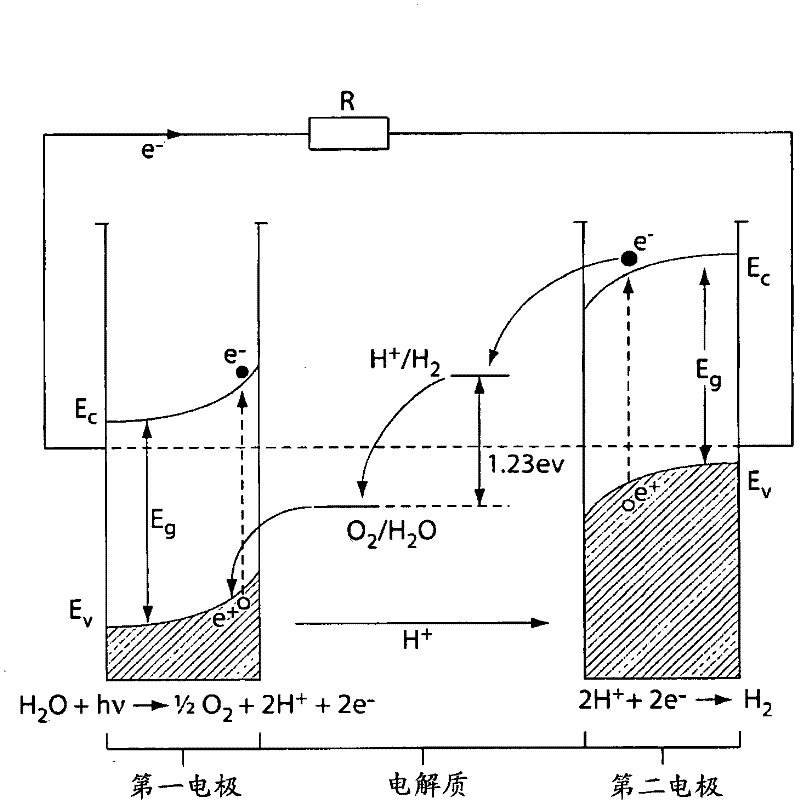

A photoelectrochemical cell and catalytic material technology, applied in the field of compositions for forming photoanode, can solve problems such as low energy conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0249] The following examples describe non-limiting examples of methods of depositing cobalt-containing catalytic materials (Co-OEC) on photoactive materials such as semiconductor CdS. In this embodiment, the method comprises: providing a solution comprising a metal ionic species and an anionic species, providing a photoactive electrode, and disabling the metal by applying a voltage to the photoactive electrode (e.g., by an external power source or by exposure to a light source). The ionic species and said anionic species form the catalytic material associated with the photoactive electrode.

[0250] Material. Cadmium sulfate, thiourea, ammonium acetate, ammonium hydroxide solution (28% NH 3 ), cobalt nitrate, methylphosphonic acid (Aldrich) and fluorine-doped tin oxide (FTO) coated glass substrates (Solaronix) were used as received.

[0251]CdS film preparation. CdS thin films were prepared on FTO-coated glass substrates by chemical bath deposition technique. 100 mL of de...

Embodiment 2

[0255] The following prophetic examples describe methods of forming Co-OEC functionalized photoanodes and characterization of enhanced light-assisted water oxidation reaction rates.

[0256] Nanostructures growable on conductive FTO-coated glass substrates by atmospheric chemical vapor deposition (CVD) techniques described previously (see for example Kay et al. J.Am.Chem.Soc, 2006, 128, 15714-15721) Iron oxide semiconductor (α-Fe 2 o 3 ). The substrate can then be connected to a potentiostat as a working electrode and immersed in 0.1M KPi (pH 7) and 0.5mM Co(NO 3 ) 2 in the solution. The electrodes can then be biased at 1.1 V vs. Ag / AgCl reference for electrodeposition of Co-OEC catalysts as described in Example 1 and as previously performed for ITO electrodes (see, e.g., Kanan et al., Science, 2008, 321, 1072). The resulting α-Fe 2 o 3 The / Co-OEC electrode can then be used as a photoanode.

[0257] with α-Fe alone 2 o 3 photoanode compared to α-Fe 2 o 3 / Co-OEC ...

Embodiment 3

[0259] The following prophetic examples describe the use of water oxidation, O 2 Non-limiting methods of gas evolution and detection using Co-OEC functionalized photoanodes.

[0260] A Co-OEC functionalized photoanode (eg, prepared according to Example 1 or 2, or otherwise as described here) can be connected to a potentiostat and used as the working electrode for this experiment. The working electrode as well as reference electrode (eg Ag / AgCl) and auxiliary electrode (eg Pt wire) can be immersed in a buffered aqueous solution (eg 1M KPi, pH 7). The entire experiment can then be sealed from the environment (e.g., using a rubber septum in the ground glass joint attached to the electrochemical cell housing) and sealed by using He gas (or other inert gas, such as N 2 , Ar) bubbling purge air. A certain bias voltage (eg 02 preparation. This can be achieved by a photoelectrochemical cell containing a certain fraction of H 2 18 Operation in water of O and m / z=34 ( 18,16 o 2 )...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com