Method for preparing nano tungsten trioxide thin film

A nano-tungsten trioxide and film preparation technology, which is applied in the field of nano-tungsten trioxide film preparation, can solve the problems that the precursor sol cannot be placed for a long time, is easily converted into a gel, and reduces photocatalytic activity and photoelectric conversion performance. Reduced preparation costs, good firmness, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Conductive glass substrate cleaning: Soak FTO conductive glass in KOH saturated isopropanol solution for 24 hours; rinse with distilled water; ultrasonically clean with distilled water for 30 minutes; ultrasonically clean with acetone for 30 minutes; ultrasonically clean with absolute ethanol for 30 minutes; Ultrasonic cleaning with deionized water for 30 minutes, then rinse 3 times, N 2 Blow dry and set aside.

[0031] Weigh 9.8g (NH 4 ) 6 W 7 o 24 ·6H 2 O was dissolved in 20ml of secondary deionized water, 5g of polyethylene glycol 1000 was added, the magnetic force was continuously stirred for 4h, and then a transparent precursor solution was obtained in a water bath at 80°C for 2h.

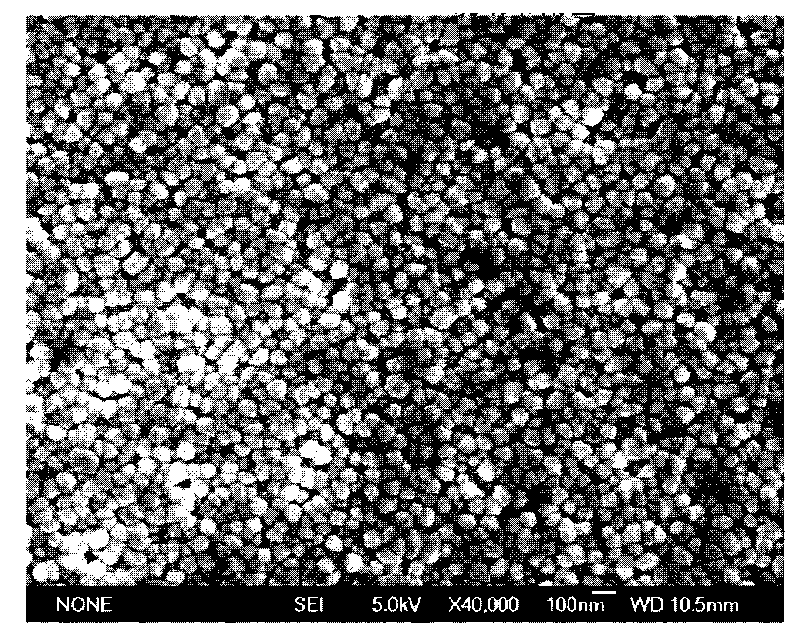

[0032] Use the dipping and pulling method to coat the film, pull the FTO conductive glass out of the prepared precursor solution at a speed of 2cm / min, let it stand for 5min, put it in an oven at 70°C to dry for 1h, and then increase the temperature at a rate of 5°C / min Rise to 50...

Embodiment 2

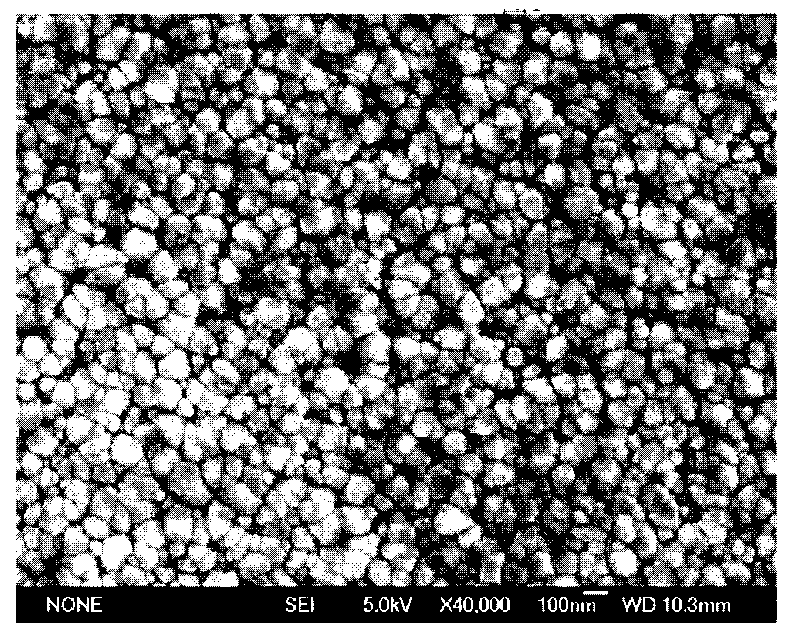

[0034] This example is similar to Example 1, the difference is that: Step 2) In addition to adding 5g of polyethylene glycol 1000, add 2.5g of citric acid, stir, and stand in a water bath to obtain a precursor solution, coating, and calcining to obtain nano Tungsten trioxide film. figure 2 It is the FESEM image of the prepared nano-tungsten trioxide film.

Embodiment 3

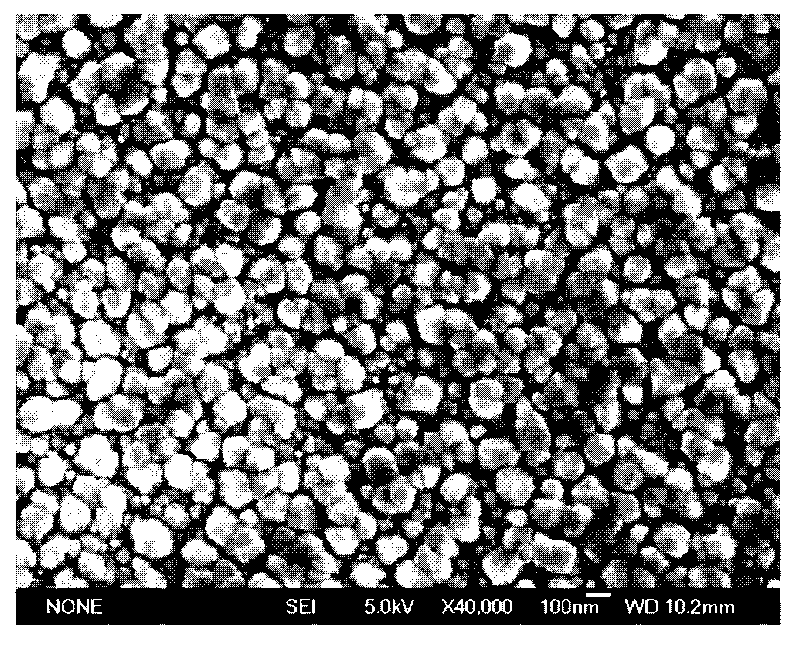

[0036] The present embodiment is similar to embodiment 1, the difference is that: step 2) weighs 9.8g (NH 4 ) 6 h 2 W 12 O·nH2 O was dissolved in 20ml of secondary deionized water, 10g of polyethylene glycol 400 and 2.5g of oleic acid were added, stirred, left standing in a water bath to obtain a precursor solution, coated, and calcined to obtain a nano-tungsten trioxide film. image 3 It is the FESEM image of the prepared nano-tungsten trioxide film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com