Flotation method for separating silver from high leaching residues

A high leaching slag and flotation technology, applied in the field of flotation process, can solve the problems such as the lack of reference materials for chemicals and metering, the difference in mineral composition, etc., and achieve the effects of low cost, high recovery rate and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] (1) Mineral raw materials:

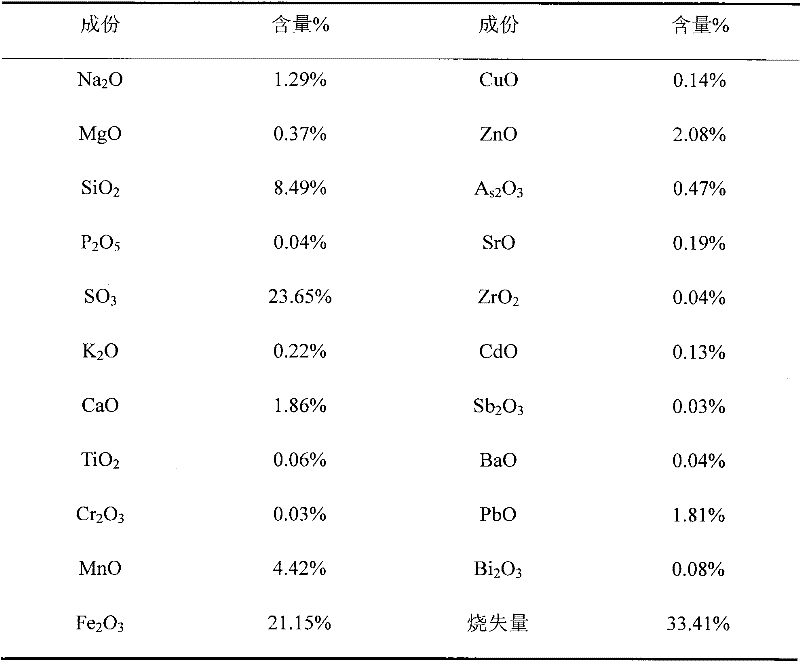

[0021] Table 1 Full analysis of ore samples

[0022]

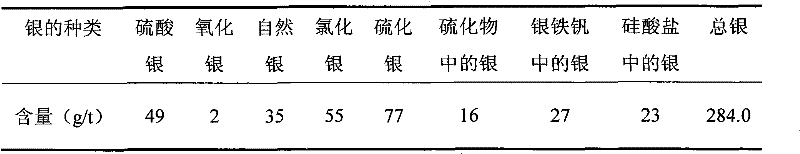

[0023] Table 2 Phases of Silver

[0024]

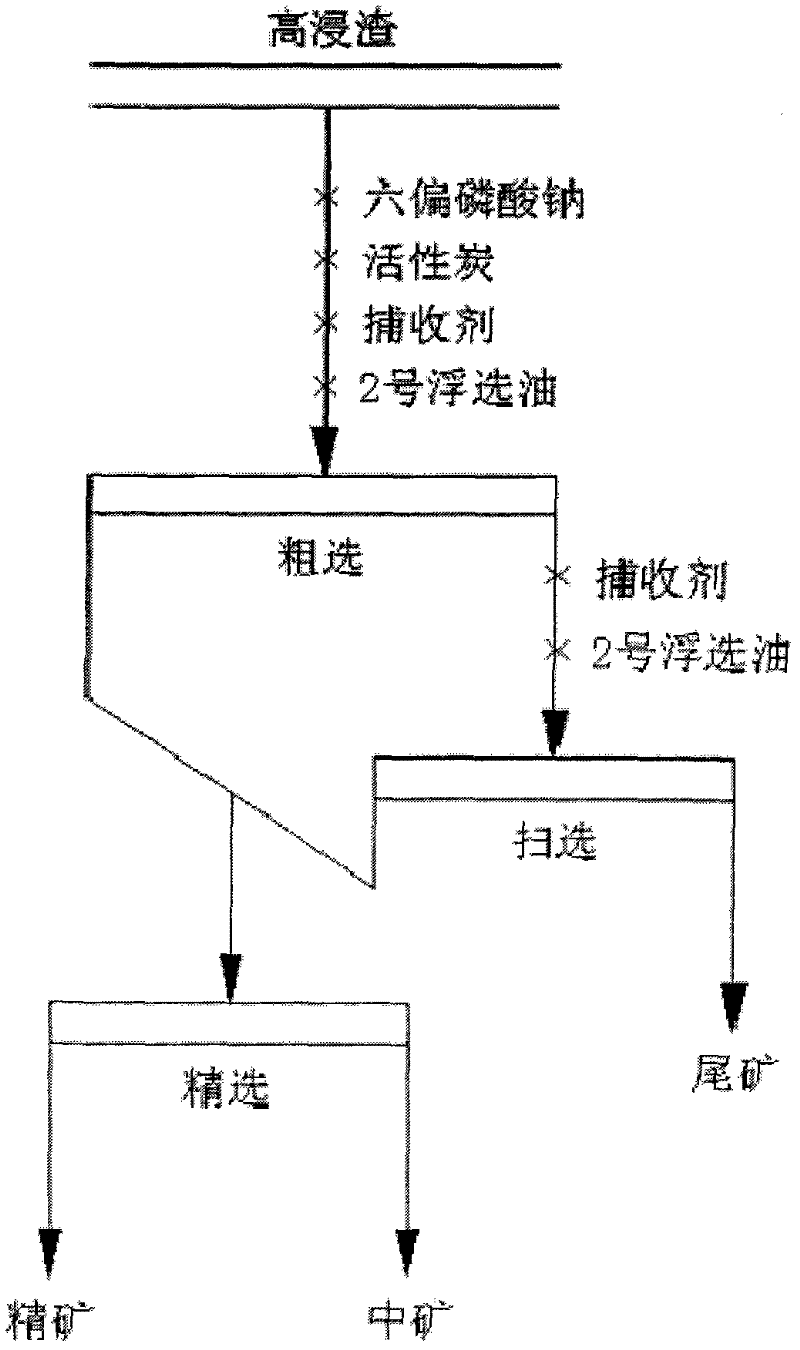

[0025] (2) if figure 1 As shown, the flotation method of the present embodiment is: silver roughing, silver sweeping and silver concentration are carried out to the high leaching slag, and the silver roughing includes the following steps: (a) adding six Sodium metaphosphate, add 120 grams of sodium hexametaphosphate per ton of high leaching residue, stir for 6 minutes; (b) add activated carbon in the flotation tank, add 2500 grams of activated carbon per ton of high leaching residue, and stir for 6 minutes; (c) Add collector and foaming agent into the flotation tank, the collector uses Z-200 and butylamine black medicine, the foaming agent uses No. The amine black drug is 600 grams, and the No. 2 flotation oil is 10 grams. The silver scavenging step includes: adding a collector and a foaming agent in the flotation cell after rough sele...

Embodiment 2

[0027] (1) mineral raw material: same as embodiment 1.

[0028] (2) if figure 1 As shown, the flotation method of the present embodiment is: silver roughing, silver sweeping and silver concentration are carried out to the high leaching slag, and the silver roughing includes the following steps: (a) adding six Sodium metaphosphate, add 135 grams of sodium hexametaphosphate per ton of high leaching residue, stir for 8 minutes; (b) add activated carbon in the flotation tank, add 3500 grams of activated carbon per ton of high leaching residue, and stir for 5 minutes; (c) Add collector and foaming agent into the flotation tank, the collector uses Z-200 and butylamine black medicine, the foaming agent uses No. The amine black drug is 700 grams, and the No. 2 flotation oil is 11 grams. The silver scavenging step includes: adding a collector and a foaming agent in the flotation cell after rough selection, the collector uses Z-200 and butylamine black medicine, and the foaming agent ...

Embodiment 3

[0030] (1) mineral raw material: same as embodiment 1.

[0031] (2) if figure 1 As shown, the flotation method of the present embodiment is: silver roughing, silver sweeping and silver concentration are carried out to the high leaching slag, and the silver roughing includes the following steps: (a) adding six For sodium metaphosphate, add 110 grams of sodium hexametaphosphate per ton of high leaching residue, and stir for 9 minutes; (b) add activated carbon in the flotation tank, add 3000 grams of activated carbon for each ton of high leaching residue, and stir for 4 minutes; Add collector and foaming agent into the flotation tank, the collector uses Z-200 and butylamine black medicine, the foaming agent uses No. The amine black drug is 650 grams, and the No. 2 flotation oil is 12 grams. The silver scavenging step includes: adding a collector and a foaming agent in the flotation cell after rough selection, the collector uses Z-200 and butylamine black medicine, and the foami...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com