Preparation method of alumina-based composite continuous fibers

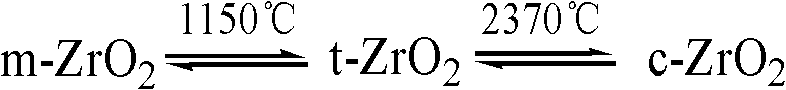

A continuous fiber, alumina-based technology is applied in the field of preparation technology of continuous alumina-based composite fibers, which can solve the problems of low alumina fiber strength, short alumina fiber length, and inability to obtain continuous fibers, and achieves dense fiber cross-section. , The effect of stable physical and chemical properties, good strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with specific examples.

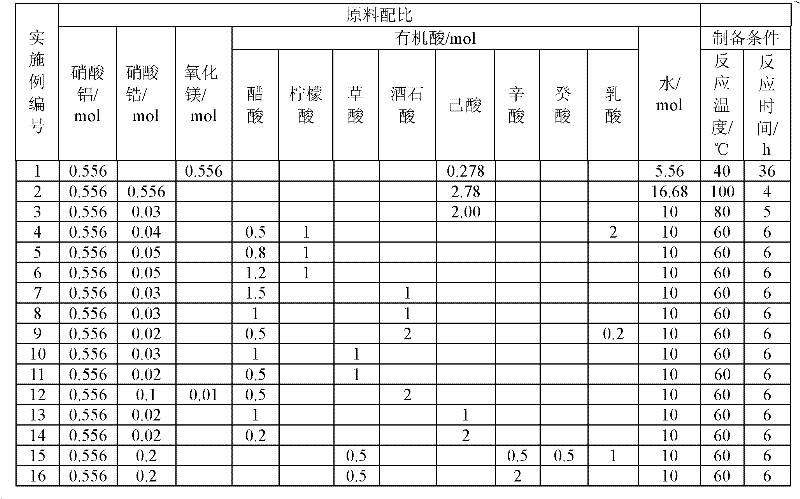

[0029] Table 1 has listed numbering as 16 embodiment first step processes of 1-16: determine the kind and the addition of aluminum nitrate, zirconium nitrate, magnesia, water, organic acid according to the different embodiments of table 1, and determine carboxylic acid The preparation conditions of the acid salt composite sol were used to prepare the carboxylate composite sol.

[0030] Table 1. Preparation of carboxylate composite sols

[0031]

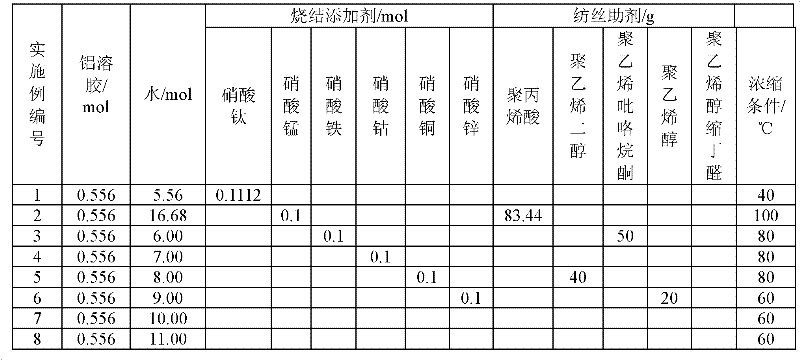

[0032]Table 2 has listed the second and third step process conditions of the embodiment of table 1: add water, sintering additives, spinning aids in the carboxylate composite sol according to the different embodiments of table 2, prepare according to the concentration conditions of table 2 Alumina-based composite fiber precursor sol. In the fourth step, the concentrated precursor sol is put into a liquid storage tank wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com