Automatic electro-spark deposition system

A kind of electric spark deposition, automatic technology, applied in the direction of metal material coating process, coating, etc., to achieve the effect of good deposition layer quality, uniform deposition layer, avoiding unstable deposition quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

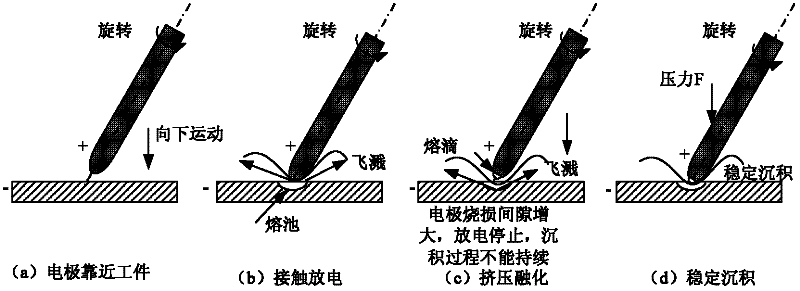

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

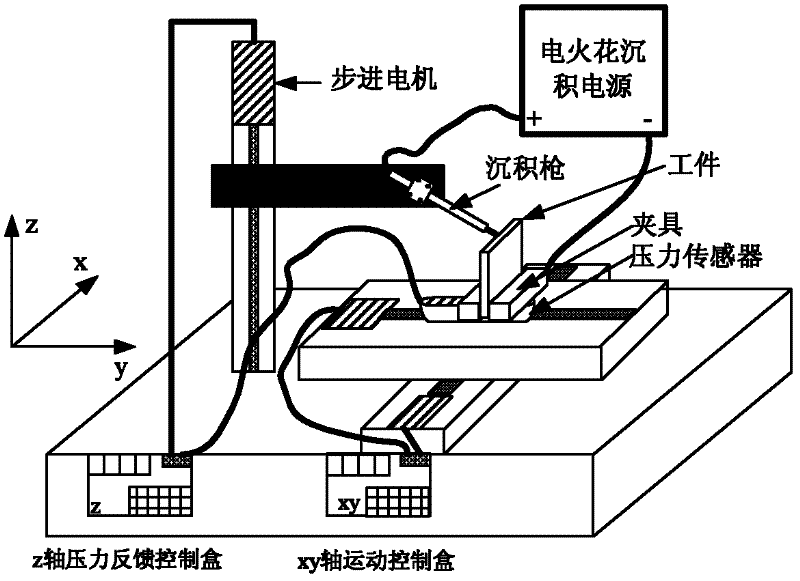

[0029] The technical scheme of the present invention adopts square 304 stainless steel as the deposition workpiece, the deposition electrode is 304 stainless steel with a diameter of 3 mm, the electrode and the workpiece are made of the same material, and the XY two-dimensional mobile platform is TDJG-I of Tianjin Automel Optoelectronics Technology Co., Ltd. type multi-axis CNC platform, the z-axis motion mechanism chooses the 57-type stepper motor 23HS4620 of Changzhou Ankete Motor Co., Ltd., and the EDM deposition equipment uses the SparkDepo-200 EDM equipment produced by TechnoCoat Company of Japan.

[0030] Fix the deposition gun on the fixture on the stepper motor, assemble the stepper motor and pressure sensor (using the existing feedback control principle and devices, the schematic diagram is as attached Figure 4 shown) to connect, set the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com