Filter cartridge dust remover with automatical and continuous dust removal function

A filter cartridge dust collector and ash cleaning technology, which is applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc. Dust collector operation performance and other issues, to achieve the effect of reliable cleaning performance, improved filtration effect, and reduced investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

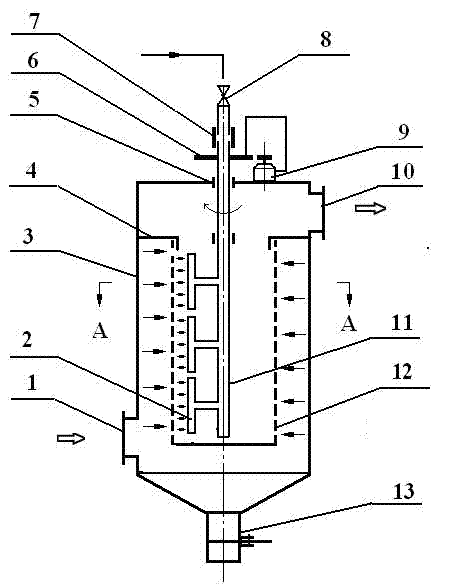

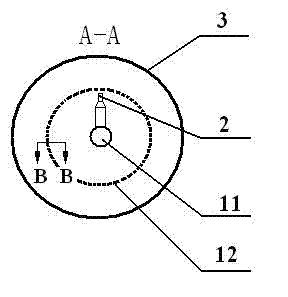

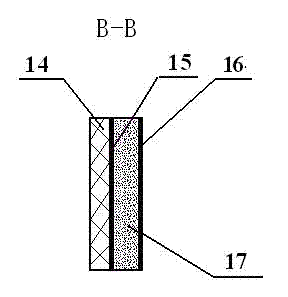

[0023] Such as figure 1 As shown, the filter cartridge 12 is fixed, and the structure in which the jet nozzle 2 rotates around the axis is: a rotating bearing 5 is installed between the compressed air delivery pipe 11 and the top surface of the housing 3 . The upper port of the compressed air delivery pipe 11 is connected to the electric valve 8; a sealing structure 7 and a transmission reduction device 6 are also arranged at the compressed air delivery pipe 11 between the electric valve 8 and the rotating bearing 5, and the compressed air delivery pipe 11 is connected to the transmission reduction device 6. The transmission reduction device 6 is connected to the air motor 9 , and the air motor 9 is fixedly installed on the top surface of the housing 3 . The compressed air delivery pipe 11 is driven to rotate by the air motor 9 and the transmission reduction device 6. The power of the air motor 9 comes from the compressed air for cleaning dust, and the speed of the compressed ...

Embodiment 2

[0025] Such as Figure 4As shown, the filter cartridge 12 is rotated around the axis, and the jet nozzle 2 is fixed. The compressed air delivery pipe 11 directly extends vertically from the top of the housing 3 to the bottom of the filter cartridge 12 , and the high-speed airflow is controlled by the electric valve 8 to enter the compressed air delivery pipe 11 from the outside and spray out through the air nozzle 2 . An electric motor 18 is arranged below the bottom of the filter cartridge 12. The electric motor 18 is connected to the bottom of the filter cartridge 12 through a rotating shaft, and the electric motor 18 drives the filter cartridge 12 to rotate. The air jet nozzle 2 sprays air to the filter cartridge 12 to remove dust, and the filter cartridge 12 rotates once to complete a filter dust removal.

Embodiment 3

[0027] Such as Figure 5 As shown, in the housing 3, two filter cartridges 12 are installed at intervals along the horizontal direction, and the two filter cartridges 12 are connected together, and the upper ports of the two filter cartridges 12 are connected by a partition, and the two filter cartridges 12 The electric valves 8 are connected in parallel, and according to the set control program, the two filter cartridges are cleaned in sequence within the specified time, or according to the given cleaning cycle. Similarly, the present invention can be extended to more than two filter cartridges 12 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com