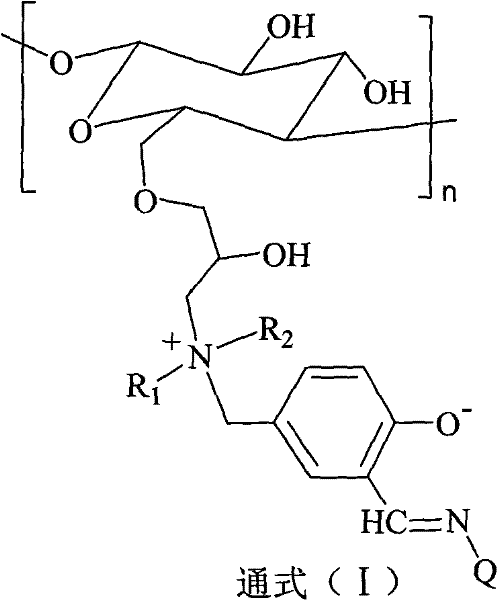

Multifunctional chelating cellulose and application thereof

A cellulose and multi-functional technology, applied in other chemical processes, water/sludge/sewage treatment, material inspection products, etc., can solve the problems of difficult recycling, complex use conditions, high production costs, etc., and achieve simple manual operation Ease of operation, less waste, and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

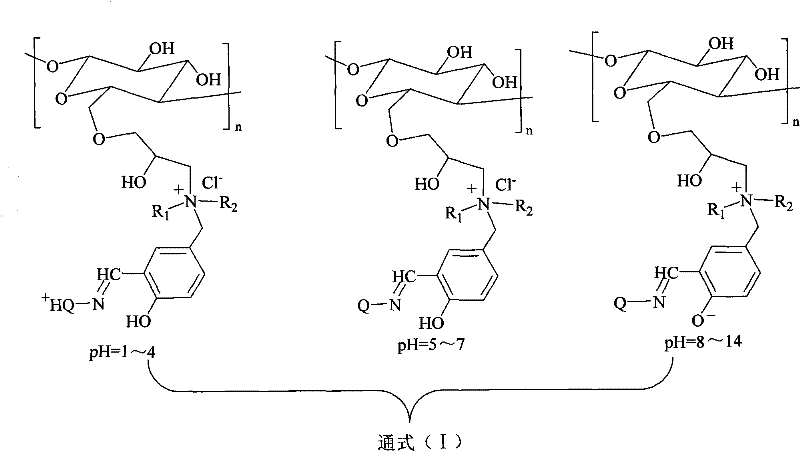

Method used

Image

Examples

Embodiment 1

[0034] Example 1 Preparation, properties and application of I-M-1 type multifunctional chelated cellulose

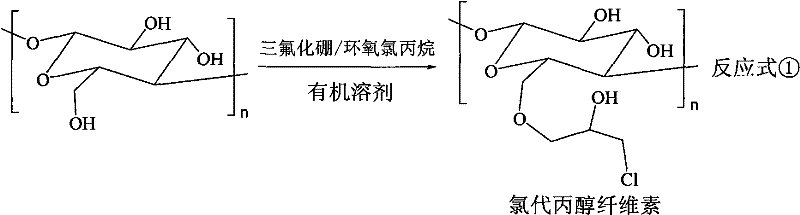

[0035] Step 1 Preparation of chloropropanol cellulose

[0036]

[0037] Weigh 100 grams of commercially available dry pulp cellulose and 230 grams of ethyl acetate, stir together and heat up at 80 to 95 °C for 4 hours and swell for 4 hours, then add 1.3 grams of catalyst 1.3 grams of boron trifluoride ether solution, drop 32 grams of epichlorohydrin , and react for 1 hour. Pressed, filtered, taken out, and dried to obtain 131.3 g of chloropropanol cellulose. Elemental analysis showed that the chlorine content was 9.97%.

[0038] Step 2: Preparation of dimethylaminopropanol cellulose

[0039]

[0040] The chloropropanol cellulose obtained in step 1 is put into 350 grams of dimethylamine aqueous solution with a concentration of 40% by mass, and the temperature is stirred and heated to 60-65° C. for 48 hours. The solid-phase reaction product was removed by pressing a...

Embodiment 2

[0048] Example 2 Preparation of I-M-2 type multifunctional chelated cellulose

[0049]

[0050] Taking the salicylaldehyde methylate cellulose and o-aminophenol obtained in Step 3 of Example 1 as raw materials, and adopting the operation method of Step 4 of Example 1, an orange-yellow I-M-2 type multifunctional chelated cellulose was prepared. The fluorescence emission of I-M-2 multifunctional chelated cellulose in DMF solution was λmax=512nm. Use Zn 2+ , Pb 2+ or Cu 2+ After leaching I-M-2 multifunctional chelated cellulose with ionic aqueous solution, the fluorescence intensity of I-M-2 multifunctional chelated cellulose was obviously enhanced. I-M-2 multifunctional chelated cellulose to other Na + , K + , Mg 2+ , Ca 2+ , Ba 2+ Isofluorescence intensity does not change, I-M-2 multifunctional chelated cellulose adsorbs Hg 2+ , Cd 2+ or Cr 3+ Then, the fluorescence of I-M-1 multifunctional chelated cellulose was quenched.

Embodiment 3

[0051] Example 3 Preparation of I-M-3 type multifunctional chelated cellulose

[0052]

[0053] Taking the salicylaldehyde methylate cellulose and 8-aminoquinoline obtained in step 3 of Example 1, and adopting the operation method of step 4 of Example 1, bright orange-red I-M-3 multifunctional chelated cellulose was prepared.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com