Pleurotus nebrodensis polysaccharide-containing moisturizing cosmetic and preparation method thereof

A technology of Linggu polysaccharides and Bailing mushrooms, applied in the field of optimized preparation of Bailing mushroom polysaccharides, can solve problems such as low efficiency, destruction of polysaccharide three-dimensional structure, and changes in biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

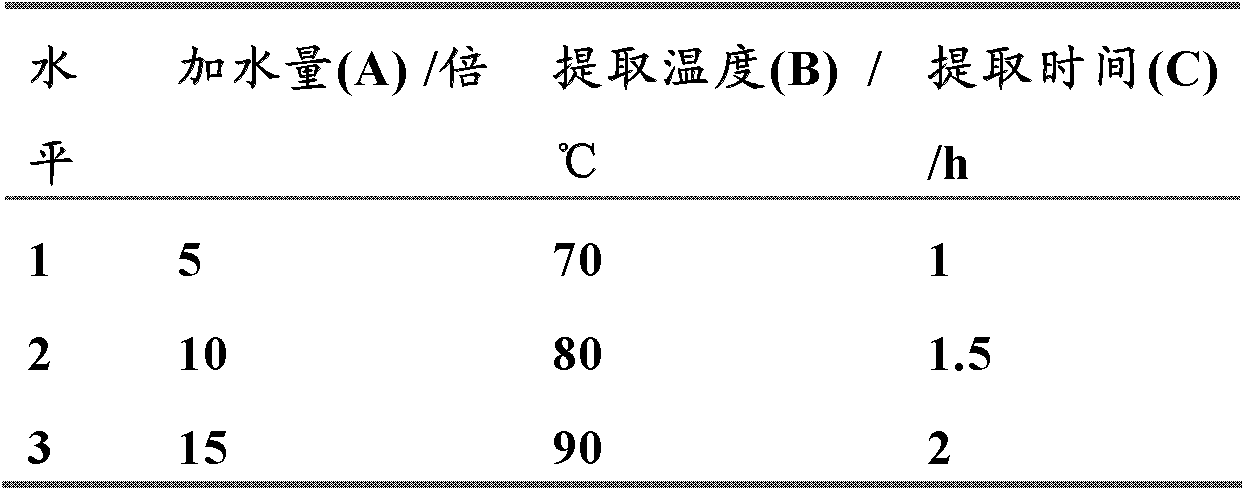

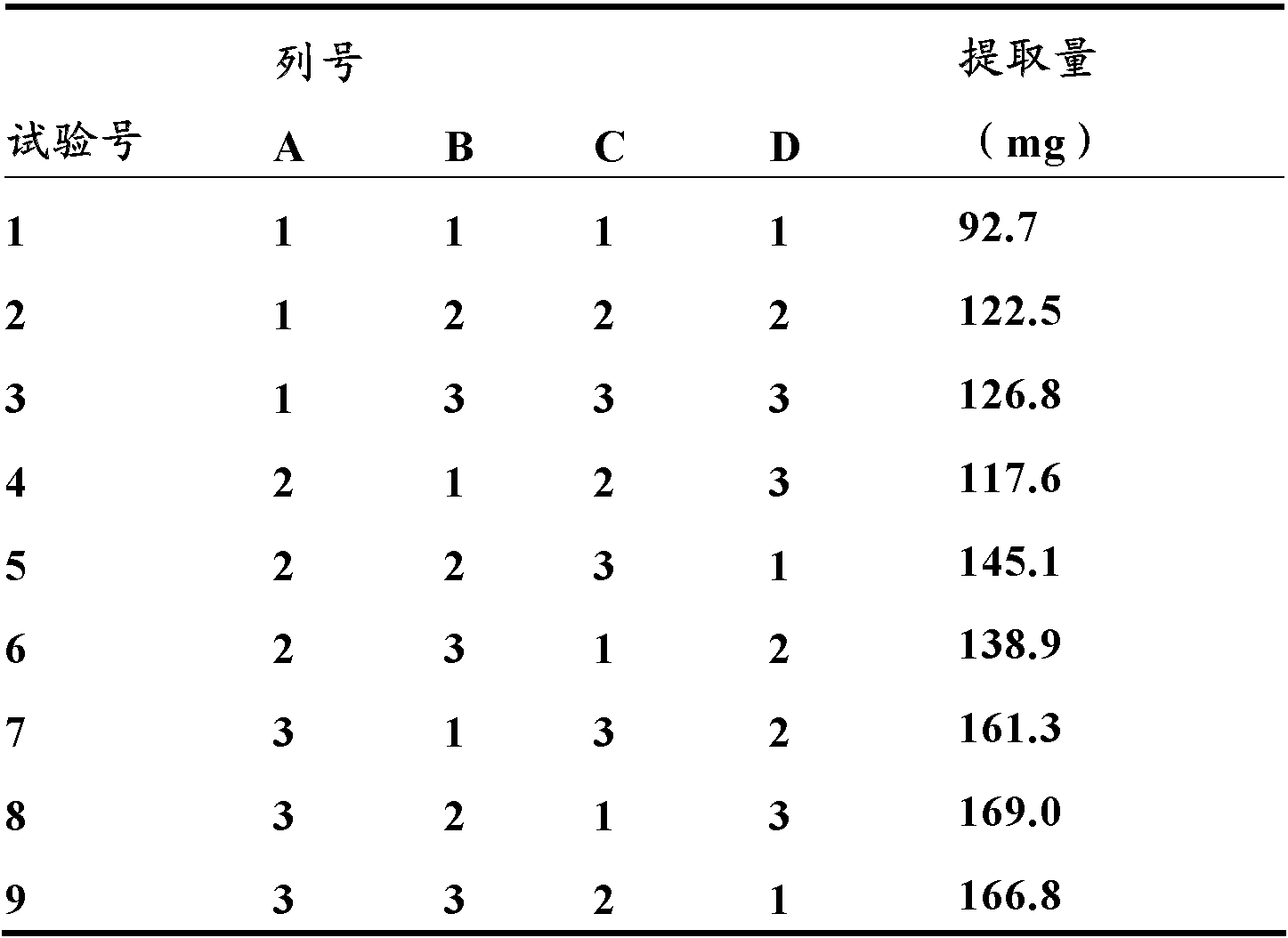

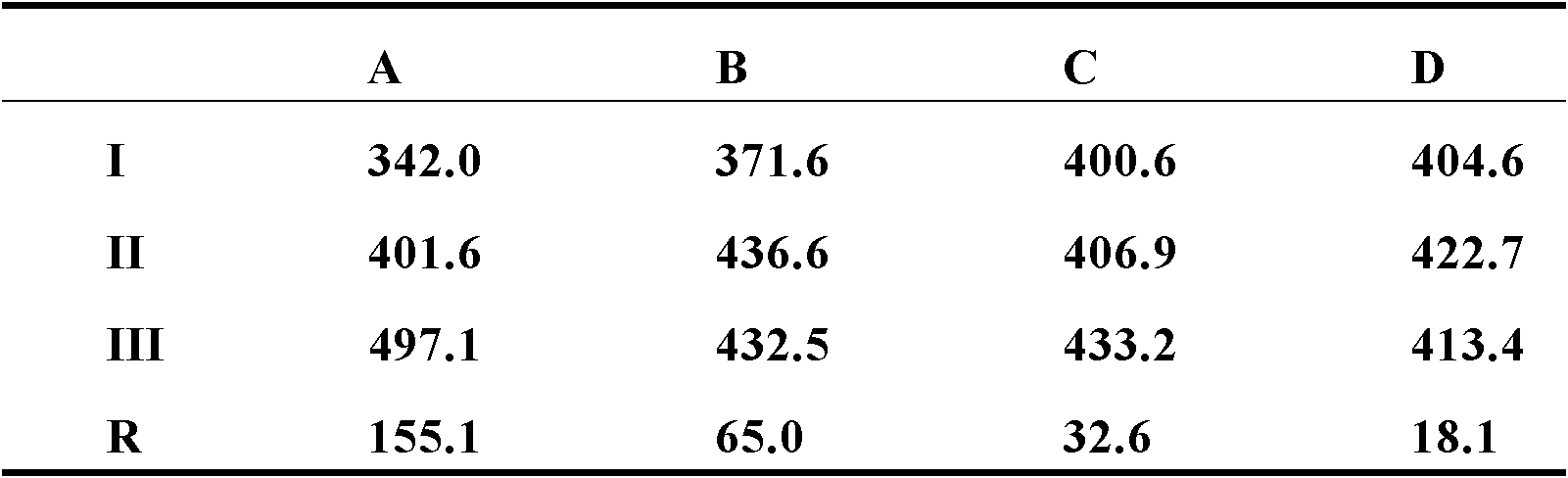

[0024] The optimization of embodiment 1 Bailing mushroom polysaccharide extraction conditions

[0025] (1) Determination of polysaccharide content

[0026] Accurately weigh 80.0 mg of anhydrous glucose dried at 105°C to constant weight, dissolve in distilled water and make up to 100 ml, then dilute 10 times to prepare a 0.08 mg / ml standard solution. Accurately draw 0.5ml, 1.0ml, 1.2ml, 1.5ml, 2.0ml of the standard solution, put them in dry test tubes respectively, add 2.0ml of distilled water, shake well, add 0.2% anthrone sulfate 4.0ml, shake well quickly. After 45 minutes, use 2.0ml of distilled water plus 4.0ml of chromogen as a blank, and measure at 625nm respectively. Draw a standard curve with the absorbance Y as the ordinate and the concentration as the abscissa X (mg / ml). Get the regression equation Y=14.73X-0.0186, r=0.99954

[0027] Anhydrous glucose has a good linear relationship in the range of 0.02-0.08mg / ml.

[0028] Take an appropriate amount of the dried Ba...

Embodiment 2

[0042] The preparation of embodiment 2 Bailing mushroom polysaccharide

[0043] Add 500 g of fresh Bailing mushroom, add 5 L of water, crush it with a tissue grinder, and extract it in a dynamic countercurrent cycle at 75 °C (TQ type dynamic cycle countercurrent extraction equipment, Zhejiang Erle Drying Equipment Co., Ltd.) for 1.0 hour. After centrifugation, the extract was continuously passed through two neutral alumina columns (100 mesh, Sinopharm Chemical Reagent Co., Ltd., 2mm in diameter, 25cm in height) for decolorization. Concentrate under reduced pressure (temperature 70-80°C, vacuum <-0.08MPa) to extract relative density 1.05, add ethanol until the alcohol content is 85% by volume, and produce white flocculent precipitate. After the precipitate was centrifuged, it was washed twice with 85 volume % ethanol and 95 volume % ethanol respectively to obtain 5.6 g of Bailing mushroom polysaccharide.

[0044] The extraction yield of Bailing mushroom polysaccharide is 1.12%...

Embodiment 3

[0045] The preparation of embodiment 3 Bailing mushroom polysaccharide

[0046]Add 2000g of fresh Bailing mushroom to 20L of water, crush it with a tissue grinder, and then extract it in a dynamic countercurrent cycle at 90°C for 1.5 hours. After centrifugation, the extract was continuously decolorized through two neutral alumina columns (100 mesh, 100 mesh, Sinopharm Chemical Reagent Co., Ltd. 3 mm in diameter and 50 cm in height). Concentrate until the relative density of the medicinal solution is 1.07, add ethanol until the alcohol content is 85% by volume, and produce white flocculent precipitate. After the precipitate was centrifuged, it was washed twice with 85 volume % ethanol and 95 volume % ethanol respectively to obtain 30.8 g of Bailing mushroom polysaccharide.

[0047] The extraction yield of Bailing mushroom polysaccharide is 1.54% by weight. The water content of the fruiting body of Bailing mushroom is about 80% by weight. Therefore, the extraction yield is ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com