Method for determining content of free nicotine in tobaccos and tobacco products

A technology of tobacco products and determination methods, which is applied in the direction of measuring devices, material separation, instruments, etc., can solve the problems of environmental damage of free nicotine, and achieve the effects of accurate and reliable measurement results, accurate measurement results, and less use of solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The main reagents and instruments used

[0040] Nicotine: purity ≥ 99%;

[0041] n-Hexane: chromatographically pure, Fisher Company, USA;

[0042] 3R4F reference cigarette, University of Kentucky, USA;

[0043] Gas chromatography / mass spectrometry with headspace solid-phase microextraction autosampler, model 6890 / 5973, Agilent, USA;

[0044] ZB-624 elastic capillary column with 14% cyanopropylbenzene and 86% dimethyl polysiloxane, with a length of 30 m, an inner diameter of 0.32 mm, and a film thickness of 1.8 μm, Phenomenex, USA;

[0045] 65 μm polydimethylsiloxane / styrene solid-phase microextraction head, partially cross-linked, Supelco, USA;

[0046] Analytical balance, with a sensitivity of 0.1 mg;

[0047] Manual micro-sampling needle;

[0048] Brown volumetric flasks of various specifications;

[0049] 1. Establishment of standard working curve

[0050] 1.1 Preparation of blank samples

[0051] Grind 50 g of shredded tobacco into powder, add 1 L of 2% NaOH a...

Embodiment 2

[0092] Carry out according to embodiment 1, and make corresponding adjustments in the following aspects:

[0093] The 2002 Chongqing Wanzhou Burley tobacco sheet and the 2009 Qujinghong large sheet tobacco were respectively selected, and the above two samples were shredded to obtain shredded tobacco samples with a cutting width of 0.9 mm. Tobacco dust samples were obtained by grinding the shredded tobacco through a cyclone mill. The above six samples of tobacco sheet, shredded tobacco, and tobacco powder were respectively tested for free nicotine in the samples, and the results are shown in Table 5. The results show that the determination result of the tobacco powder is higher than that of other forms of tobacco products, so the method adopts the tobacco powder as the experimental object.

[0094]

Embodiment 3~5

[0096] Carry out according to embodiment 1, and make corresponding adjustments in the following aspects:

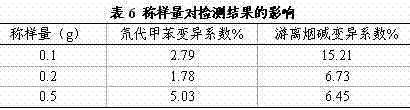

[0097] In order to investigate the impact of different sample weights on the test results, Example 3 adopted a 0.1 g sample weight, Example 4 adopted a 0.2 g sample weight, and Example 5 adopted a 0.5 g sample weight. Under different weighing conditions, 5 samples were processed in parallel, and the coefficient of variation of the test results of the samples was investigated. The test results showed that: when the weighing amount was 0.2 g, free nicotine and deuterated toluene met the analysis and test requirements, and the results are shown in Table 6. .

[0098]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com