Direct coal hydrogenation liquefaction catalyst and direct coal hydrogenation liquefaction method

A technology for hydrogenation and liquefaction and catalyst, which is applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., to achieve high liquefaction efficiency, low reaction temperature, and high catalytic activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

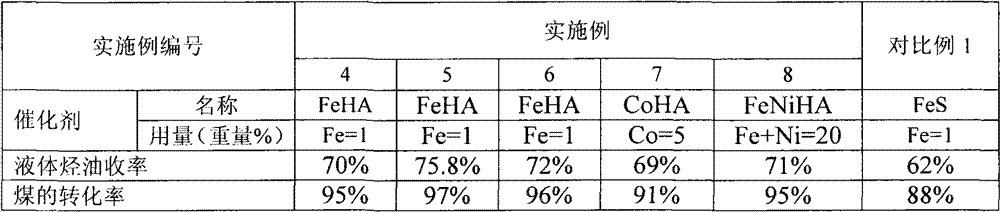

Examples

Embodiment 1

[0038] Take 100 grams of water, add 20 grams of FeSO 4 ·7H 2 O, stir and dissolve evenly, then add 30 grams of humic acid (Xinpeng Biological Engineering Co., Ltd.), stir evenly, control the temperature at 60-70°C, and blow air into it with a blower under stirring conditions, and add a concentration of 10% by weight % ammonia solution, control the pH value to become alkaline (about 8), react for 3 hours, then cool to room temperature, filter off moisture, dry and remove moisture at 100°C, grind into powder to obtain iron humic acid of the present invention (FeHA) catalyst 40.28 grams, wherein the content of iron element is 10% by weight.

Embodiment 2

[0040] Take 100 grams of water, add 15 grams of cobalt nitrate hexahydrate, stir and dissolve evenly, then add 40 grams of humic acid (Huozhou Jiayou Humic Acid Factory), stir evenly, control the temperature at 70-90 ° C, and stir , Blow in air with a blower, and add ammonia solution with a concentration of 15% by weight, control the pH value to be alkaline (about 9), react for 4 hours, then cool to room temperature, filter out moisture, and dry at 100 ° C to remove After moisture, it was ground into powder to obtain 40.4 grams of cobalt humic acid (CoHA) catalyst of the present invention, wherein the content of cobalt element was 5% by weight.

Embodiment 3

[0042] Take 150 grams of water, add 10 grams of FeSO 4 ·7H 2 O and 20 grams of sulfur hydrated nickel nitrate, stirred and dissolved evenly, then added 30 grams of humic acid (Huozhou Jiayou Humic Acid Factory), stirred evenly, controlled temperature at 80 ° C, under stirring conditions, feed oxygen, and Adding a concentration of ammonia solution of 20% by weight, controlling the pH value to become alkaline (about 10), reacting for 2 hours, cooling to room temperature, filtering off moisture, drying at 100°C to remove moisture, and grinding into powder to obtain this product 40.3 grams of the inventive iron-nickel humic acid (FeNiHA) catalyst, wherein the content of iron and nickel is 15% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com