High-aluminum aluminum bronze alloy solder machining method

A technology of bronze alloy and processing method, which is applied in the direction of metal processing equipment, manufacturing tools, welding/cutting media/materials, etc., can solve the problems of low production efficiency, high processing deformation hardening rate, environmental pollution, etc., and achieve processing cost reduction, Effect of improving corrosion resistance and reducing processing steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is further described below.

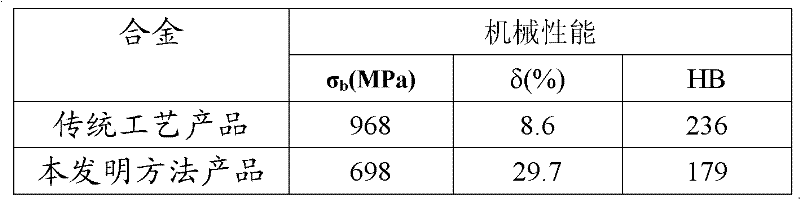

[0010] The processing method of high-aluminum aluminum bronze alloy brazing material is carried out according to the following steps: firstly, the alloy containing Al: 10.4-10.6%, Fe: 3.8-4.2%, Si: 0.06-0.08%, Pb: 0.004-0.01%, Mn: 0.45 -0.5%, the balance is the cast slab (diameter 8mm) of Cu to carry out heat treatment, heat 2 hours under the temperature of 600 degree in the furnace, cool to 200 degree in the furnace, move to room temperature and cool to room temperature; The second cold drawing, annealing and pickling, cold drawing from 8mm in diameter to 4mm in diameter, and finally the second cold drawing, annealing and pickling, cold drawing from 4mm in diameter to 1mm in diameter, to obtain the finished product.

[0011] Metal plasticity is the performance of the natural properties of metals in a certain state. It is affected by its chemical composition, processing process, organizational structure and other fact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com