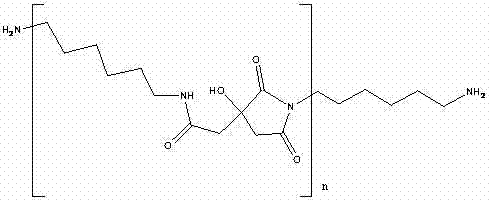

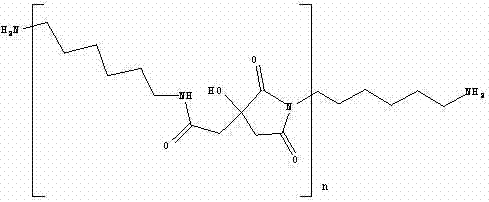

Fatty group polyamidoimide, preparation method and application thereof

A polyamide-imide and aliphatic technology, which is applied in the field of polymer compound preparation, can solve the problems of difficult processing and molding, high rigidity, etc., achieve simple and gentle synthesis process, improve softness and solubility, and overcome poor solubility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

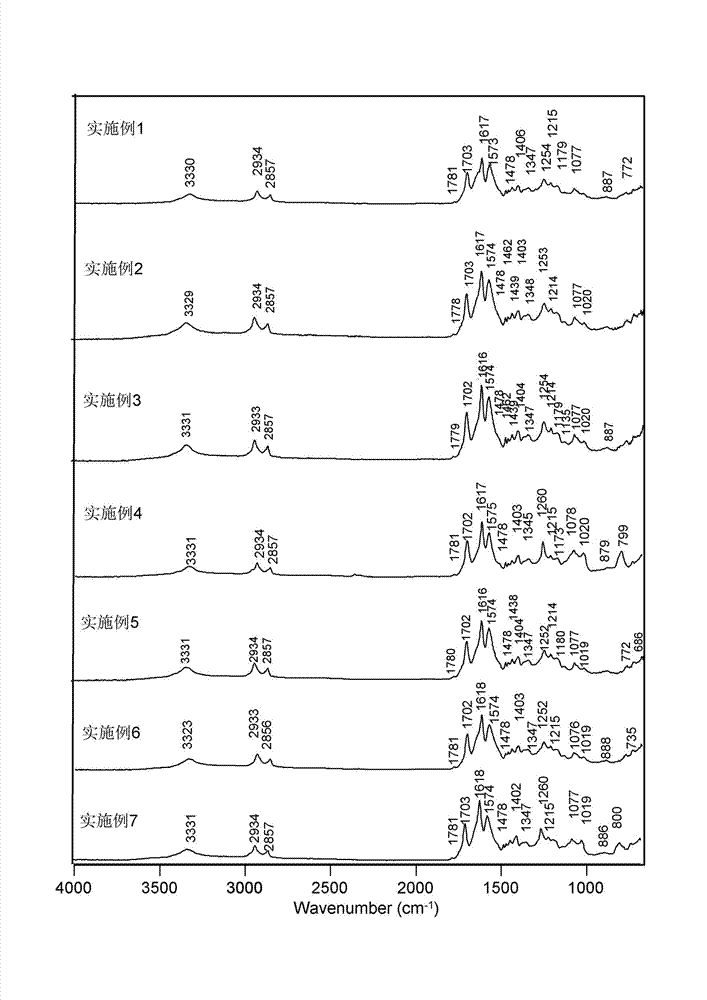

Embodiment 1

[0033] According to the molar ratio of reactant HDI and CA 3:2, weigh CA 1.9214 g, HDI 2.400 ml, add DMAc solvent 30.0 ml, add catalyst 4-dimethylaminopyridine 0.0126 g at 60 o C temperature was reacted for 12 hours, and the product was precipitated and filtered with a mixture of 45 ml of water and 15 ml of ethanol, and at 60 o After drying in a C oven for 12 hours, a solid soluble polyamide-imide was obtained. Yield 69%.

Embodiment 2

[0035] Method is the same as Example 1, but the reaction time is 6 hours. Yield 79%.

Embodiment 3

[0037] Method is with embodiment 2, but does not add catalyzer, and temperature of reaction is 70 o c. Yield 78%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com