Miniature projection liquid crystal on silicon (LCOS) optical engine

An optical engine and micro-projection technology, applied in optics, optical components, light sources, etc., can solve the problems of low optical utilization and power consumption, miniature projector structure reduction, violation of micro-projection, etc., and achieve low manufacturing cost and high optical quality. The effect of utilizing the utilization rate and improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

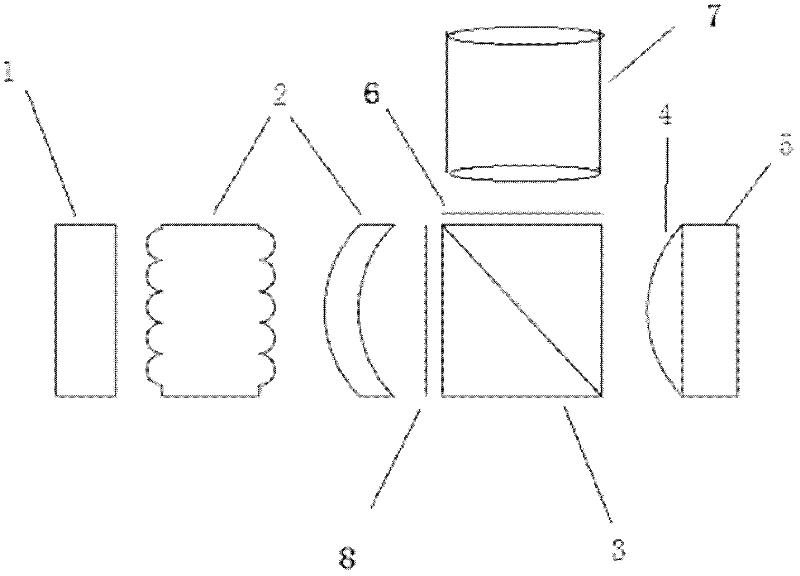

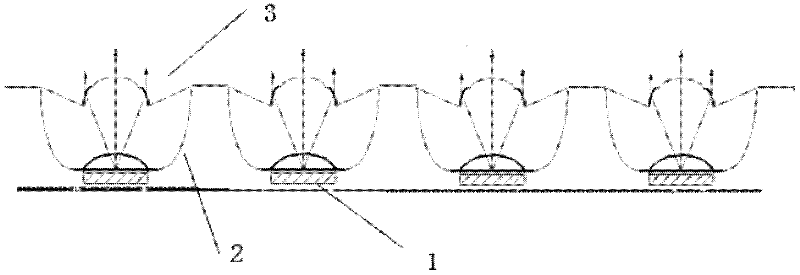

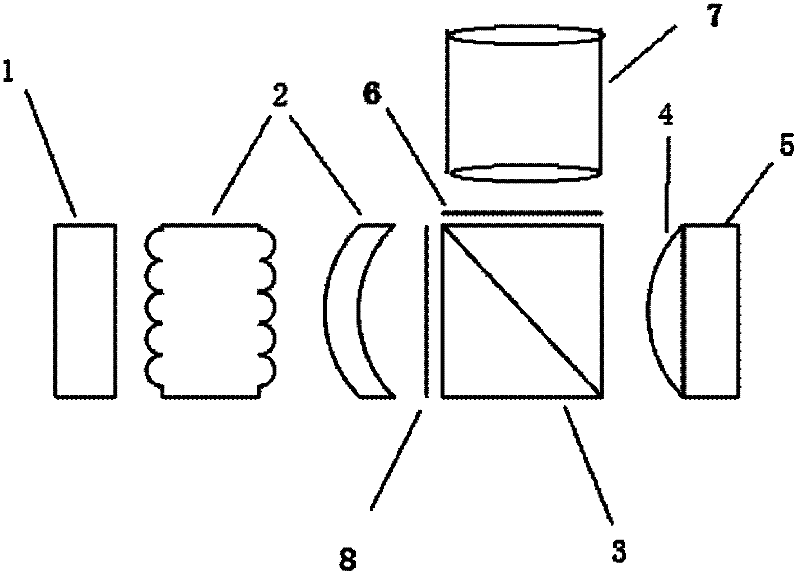

[0012] Embodiment one: if figure 1 The micro-projection LCOS optical engine system of the shown embodiment is provided with a surface light source module 1, an array lens combination 2, a PBS prism 3, a field lens 4, an LCOS chip 5, a polarizer 6, and a projection module 7 in sequence along the light propagation direction. , UV absorbing sheet 8. The surface light source module 1 uses a plurality of high luminous efficiency and low power white LEDs to form an array, such as figure 2 The structure diagram of the surface light source module shown in , and the structure diagram of the parabolic reflective bowl and the improved Fresnel lens shown in Figure 3. 2 in Figure 3 is a parabolic reflective bowl, which is coated with a cold reflective film inside, which can reflect visible light and pass through infrared and ultraviolet radiation, thereby reducing the amount of harmful radiation entering the optical system. The light with a large divergence angle is reflected by the ref...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com